Self-Assessment Tool - BRC Global Standards

advertisement

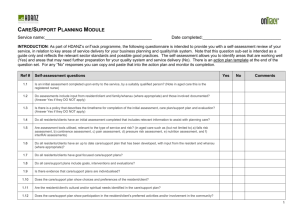

Self-Assessment Tool BRC Global Standard for Consumer Products Issue 3 Welcome to the BRC Global Standards Self-Assessment tool We hope that you will find this useful when preparing your site for an audit against the BRC Global Standard for Consumer Products issue 3. How to use the BRC Global Standards Self-Assessment tool This tool is a checklist designed to help you assess your operation against the requirements of the Standard and help to highlight any gaps so that you can prepare for your certification audit. The checklist covers each of the requirements of the Standard and may be used to check your site’s compliance with each of these requirements. The checklist also allows you to add comments or identify areas of improvement in the empty boxes provided in each section. Remember that it is not necessary to meet the requirements of all of the clauses unless you have a site making Group 1 products. The clauses are shaded so that you can easily identify if they are relevant to your Product Group. At the end of the self- assessment tool there is a copy of the decision trees used to determine which Product group is appropriate for the site (see also The Standard pp11-15 for further detail on this topic). It is recommended that sites study this carefully and are clear about which Product Group they are using before they use the self-assessment tool While we hope that this tool is useful in helping you prepare for your audit it should not be considered as evidence of an internal audit and will not be accepted by auditors during an audit. Training The BRC Training Academy has courses available to improve the understanding of the requirements for the BRC Global Standard for Consumer Products issue 3 and may be useful for the person using the BRC Global Standards Self-Assessment Tool. For further information on the courses available please visit www.brctrainingacademy.com Further Information If you have any further questions about the BRC Global Standards Self-Assessment Tool or the BRC Global Standard for Consumer Products issue 3 please do not hesitate to contact the BRC Global Standards team Email – enquiries@brcglobalstandards.com Telephone – +44 20 7854 8939 CP030 Released 1/8/2012 Self-Assessment Tool Page 1 Section 1 Senior Management Commitment and Continual Improvement Fundamental Clause The company's senior management shall demonstrate that they are fully committed to the implementation of the requirements of the Global Standard for Consumer Products (referred to as The Standard). This shall include provision of adequate resources, effective communication, systems of review, and actions taken to identify and effect opportunities for improvement. Requirement Comments Clause Prod Group 1.1 All The company's senior management shall ensure that product safety and quality objectives are established, documented, monitored and reviewed at least annually. 1.2 All 1.3 All The senior management review process shall be documented and shall include an evaluation of: Internal, customer, and external (third party) audits; previous management review documents, corrective action plans, and timeframes; customer performance indicators, complaints, and feedback; incidents, non-conforming materials and corrective actions; an assessment of process performance; a review of the product risk assessment system; a review of the results of monitoring and testing; developments in legal requirements or scientific information associated with the products in scope; resource requirements. The decisions and actions agreed shall be effectively communicated to appropriate staff and the actions implemented within the agreed timescales. Records should be updated to show when actions have been completed. 1.4 All CP030 Released 1/8/2012 The company's senior management shall provide the human and financial resources required to implement and improve the processes of the quality management system, the product risk assessment plan, and to address legal, product safety, and product quality matters. Self-Assessment Tool Page2 1.5 All There shall be clear communication and regular reporting of the functioning of, and compliance with, the Standard to senior management by the staff responsible. This shall include suggestions for improvement. 1.6 All The company shall have a current, original copy of the Standard available on site. 1.7 1&2 Where required by legislation, the site shall be registered with or approved by the appropriate government agency and evidence of this shall be available. Section 2 Risk Management Fundamental Clause The company shall have a management process in place to assure product safety, legality and quality, based on risk assessment principles. Sites must be aware of and refer to up-to-date legislation, product standards, codes of practice, and developments in science or technology that may impact risk concerning their products and packaging where these exist in the regions of intended sale. Product Scope and group determination 2.1 2.1.1 All The company shall identify the range of products it wishes to include in the scope of certification and the countries/states or regions for which the products are to be made available for sale. 2.1.2 All The company shall establish and document the product group(s) assigned to the products in scope, derived from application of the questions indicated in the decision tree (see The Standard Section II, 3.4). CP030 Released 1/8/2012 Self-Assessment Tool Page3 2.2 Legislative and safety requirements The company shall have and use a system, which may comprise internal and/or external resources, to demonstrate knowledge of all legislation, product standards, product safety issues, scientific and technical developments, and industry/customer codes of practice in the regions of intended sale relevant to the products in scope. 2.2.1 All 2.2.2 All If the company relies on information concerning product safety, quality, and legality provided by their customer or related party, it shall validate the information received and document the validation process. 2.2.3 All A documented process shall exist for incorporating changes in legislation, standards, etc. into the company’s procedures in a timely fashion, which shall be before any official implementation date of the relevant change. 2.2.4 All Copies of applicable legislation, standards, codes of practice, and similar documents shall be available to relevant staff. 2.3 2.3.1 CP030 Released 1/8/2012 Risk assessment - prior to production All A design specification covering each product shall be documented, dated, and authorized. This shall include all relevant information. As a guide, this may include the following, although this is not an exhaustive list: composition, size, color; bills of materials; assembly diagrams; primary packaging; intended shelf life; warnings or instructions for use; use, misuse, usage patterns; productions volumes. Any changes to the product design shall be documented and dated. Self-Assessment Tool Page4 2.3.2 All The company shall determined and list the legal statutes and mandatory standards applicable to each product and to the materials from which it is made, relevant in the regions of intended sale. 2.3.3 All 2.3.4 All The company shall ensure that a product hazard and risk assessment is available and clearly identifies: the hazards, the risk level for each hazard and whether the risk is acceptable; the person responsible for the assessment; the date performed and the evidence (for example, sample drawings, computer graphics) from which the assessment was derived. This risk assessment may be provided by internal or external resources. If the product requires modification, a new risk assessment shall be completed on the modified design. No products deemed to present an unacceptable risk by the assessment described in clause 2.3.3 shall be produced. 2.4 Verification of the Product Risk Assessment 2.4.1 All The company shall ensure that risk assessments have been carried out by competent staff (internal or external) and shall document the way in which this is assessed. 2.4.2 All The risk assessment shall be regularly, and at least annually, reviewed (while the products are still in production) to ensure that the assessment remains up to date, takes account of complaints or incidents with the product or similar products, and reflects any changes in legislation. 2.4.3 1&2 The risk assessment shall be carried out before production begins, and completion shall be verified by a designated responsible person. If customer sign-off is part of the contract of sale, this shall be obtained. CP030 Released 1/8/2012 Self-Assessment Tool Page5 2.4.4 1&2 Where there is legal requirement to do so or when it is necessary to confirm its safety or legality, a representative product should be submitted for testing to a suitably qualified and accredited laboratory (internal or external). The results of the test should form part of the risk assessment. 2.4.5 1&2 2.4.6 1&2 Aspects of the product design/materials that are critical to safety and which must be maintained in production shall be established with the risk assessment provider and the control limits set on these features or materials. Where legally required, the identity, qualifications, and/or license of the person producing the safety review or risk assessment shall be documented and verified. Management System Section 3 3.1 Policy statement 3.1.1 All 3.1.2 All 3.2 3.2.1 Statement of Intent CP030 Released 1/8/2012 The policy shall state the company's intention to produce safe and legal products to the specified quality (and to meet its responsibility to its customers). This shall include the commitment for review and continual improvement. The company's senior management shall ensure the policy statement is communicated to and understood by all staff involved with activities relating to product safety, legality, and quality. General Documentation requirement Documentation Control The company's senior management shall ensure that all documents records, and data critical to the management of product safety, legality and quality are in place and effectively controlled. Self-Assessment Tool Page6 3.2.1.1 All All documents in use shall be the current versions, authorized and dated, and a procedure shall be in place to ensure that obsolete documentation is removed from use. 3.2.1.2 All Documents shall be clearly legible, unambiguous, in appropriate languages, and sufficiently detailed to enable their correct application by staff. They shall be readily accessible to relevant staff at all times. 3.2.1.3 All Changes or amendments to documents shall be authorized and dated and the reason for the change recorded. Record Completion and Maintenance 3.2.2.1 All 3.2.2.2 All The records shall be legible, genuine, appropriately authorized, and retained in good condition for a period which takes account of the product lifetime and is consistent with the legal requirements in the country of manufacture or sale. Customer-specific requirements relevant to record retention shall be respected. The company's senior management shall ensure that procedures are operated for the collation, review, maintenance, storage, and retrieval of all records relating to product safety, legality, and quality. 3.2.2.3 All 3.2.2 3.2.3 Statement of Intent 3.2.3.1 CP030 Released 1/8/2012 All Any alterations to records shall be visible and authorized, and the justification for alterations shall be recorded. Specification & Technical information dossiers The company shall ensure that specifications exist for raw materials, components, and bought-in components including packaging, intermediate/semi-processed, and finished products and any product or service that could affect the integrity of the finished product. A technical folder shall be established for each product. Specifications shall be adequate and accurate, and shall ensure compliance with relevant safety, legislative, and customer requirements. They shall be accessible to relevant staff. Self-Assessment Tool Page7 3.2.3.2 All 3.2.3.3 1&2 3.2.3.4 1&2 3.3 Companies shall maintain a technical folder containing all relevant data (or details of where such data is located) to ensure that products meet the requirements of the Standard. For example: detailed product specification (see clause 2.3.1); bill of materials; safety data sheets on all chemicals used where relevant to the safety, legality, or quality of the product; risk assessment(s); description of the conformity assessment procedure; test reports, inspection reports; list of the legislation, product standards with which the products are manufactured to comply; production control procedures and charts; approvals by any government body (if applicable); declarations of conformity to legal requirements (if applicable). The company shall seek formal agreement of specifications with relevant parties. Where specifications are not formally agreed, then the company shall be able to demonstrate that they have taken steps to seek formal agreement. There shall be a documented procedure for the amendment and approval of specifications for all parts of the process including regular reviews to ensure adequacy and status. Organizational structure, responsibility, and management authority Statement of Intent The company shall have a clearly defined and documented organizational structure that ensures the awareness of job function, responsibilities, and reporting relationships of key staff. 3.3.1 All 3.3.2 All 3.3.3 All A named individual with relevant experience and qualifications shall be responsible for the management of the legal, quality, and safety requirements laid out in this Standard. This responsibility should not present a conflict of interest with any other responsibilities. 3.3.4 All There shall be appropriate documented arrangements in place to cover for the absence of key staff. CP030 Released 1/8/2012 The company shall have an organization chart demonstrating the structure of the company. Documented, clearly defined responsibilities shall exist and be communicated to key staff with responsibility for product safety, legality, product quality, and management systems. Self-Assessment Tool Page8 3.3.5 All 3.4 The company's senior management shall ensure that a description of general duties or work instructions is in place and communicated to all staff involved with activities relating to product safety, legality, and quality. Internal Audit Statement of Intent The company shall audit the management system to ensure that it is complied with and appropriate. Internal audits shall cover all aspects associated with the Standard. They shall be scheduled and their scope and frequency shall be established commensurate with the risks associated with the activity. Audits of aspects that directly affect safety, legality, or quality shall be conducted at least annually. Exceptions resulting in audit intervals of more than one year shall be justified by documented risk assessment. 3.4.1 All 3.4.2 All Internal audits shall be carried out by competent auditors, who shall be independent of the area of operation being assessed. Auditors shall not audit their own work. 3.4.3 All 3.4.4 All Corrective actions shall be formally agreed by the person responsible for the action and implemented within appropriate and agreed timescales. A record of all programmed internal audits and associated corrective actions shall be maintained with both conformity and nonconformity with the requirements documented. All corrective actions shall be verified to ensure satisfactory completion. 3.5 Statement of Intent CP030 Released 1/8/2012 Purchasing, Supplier Approval and performance Review The company shall control all purchasing processes which are critical to product safety, legality, and quality to ensure that procured products and services conform to defined requirements. In this context suppliers shall include subcontractors and home workers. Self-Assessment Tool Page9 3.5.1 All 3.5.2 All 3.5.3 All 3.6 All 3.7 Fundamental Clause CP030 Released 1/8/2012 The procedure shall identify whether the use of unapproved suppliers is acceptable under any emergency or unusual situations. If this is the case, the procedure shall define how exceptions are recorded and how they are handled to maintain safety, legality, and quality of the products. Customer supplied property Statement of Intent 3.6.1 The site shall have a documented supplier-approval procedure, including a list of approved suppliers for products, materials, and services impacting product safety, legality, or quality. Procedures shall be established which include clear criteria for ongoing assessment and the standards of performance required. Ongoing assessment may take the form of monitoring performance through one or more of the following, although there may be other acceptable methods: in-house checks; certificates of analysis; certificate of conformity; supplier audits; traceability checks. Records of this monitoring shall be retained for at least the lifetime of the product. The company shall review the performance of new suppliers against defined criteria within a specified "trial" period and thereafter at a specified frequency to decide the level of ongoing supplier performance monitoring. The company shall exercise care customer property (including intellectual property) while it is under the company's control or is being used by the company. The company shall identify, verify, protect and safeguard customer property including software, intellectual property, tooling, fixtures, test equipment and products. If any customer property is lost, damaged or otherwise found to be unsuitable for use, this shall be reported to the customer and records maintained. Corrective and Preventive Action The company's senior management shall ensure that procedures exist to record, investigate, analyze, and correct the cause of nonconforming products or failure to meet standards, specifications, and procedures which are critical to product safety, legality, and quality. Self-Assessment Tool Page10 3.7.1 All The company shall operate an effective system for the capture, recording, and timely investigation of nonconformities or matters reported as possible nonconformities critical to product safety, legality, or quality. 3.7.2 All 3.7.3 All 3.7.4 All Customer complaints concerning actual or potential product nonconformity shall be included in the system. An appropriate staff member shall be identified and allocated the responsibility and accountability for each corrective action. This shall be documented. The company shall ensure that effective corrective actions are taken to prevent recurrence of the problem and shall monitor and record their completion within an appropriate timescale. 3.7.5 All 3.8 Fundamental Clause 3.8.1 All 3.8.2 All 3.8.3 All 3.8.4 All CP030 Released 1/8/2012 The company shall review its processes at least annually, incorporate industry best practice, and adopt preventative measures as they become available. Traceability The company shall have a system to identify and trace product lots/batches including raw materials, components, and packaging materials and follow this from the source of the incoming material through all stages of processing to supply of the product to the primary customer, and vice versa, in a timely manner. ( Materials identified as low risk to the safety, legality, or quality of the final product may be exempted from lot traceability) Companies shall be able to identify the immediate source of all raw materials, components, and packaging materials. The products that constitute a lot/batch shall be defined and documented. This shall include products made by continuous production methods. Identification of lots/batches of raw materials including packaging, processing aids, intermediate/semi-processed products, part-used materials, finished products and materials pending investigation, shall be adequate to ensure traceability. Final products shall be suitably marked, at least on their outer packaging, to allow adequate identification and traceability. Self-Assessment Tool Page11 3.8.5 All Traceability must, in all cases, be available for each lot/batch from source of raw material to supply to the primary customer. 3.8.6 All The traceability system shall be maintained when rework or any reworking operation is performed. 3.8.7 All The company shall test the traceability system to ensure traceability can be determined from raw-material receipt to finished product and vice versa. This shall occur at a predetermined frequency, at least annually, and results shall be retained. The time taken to complete the exercise shall be measured and recorded. 3.8.8 All When the same component or raw material is sourced from more than one supplier, the traceability system shall ensure that the lots/batches from each supplier can be identified if the component/material is identified as critical to safety, quality, or legality. 3.8.9 All Changes in materials, processes, or components shall be traceable if they could affect the safety, quality, or legality of the product and formally agreed by the customer if contractually required. 3.8.10 All Subcontracted manufacture of products or components (including homeworking) must be traceable to a level appropriate to the risk. 3.8.11 1&2 The need for further traceability through the chain should be established, based on the risk assessment and any legal or specific customer requirements. 3.8.12 1&2 For continuous production processes, methods of defining traceability levels must be documented and based on the risk assessment. CP030 Released 1/8/2012 Self-Assessment Tool Page12 3.9 Management of Product withdrawal and product recall Statement of Intent The company shall have a plan and system in place to effectively manage product withdrawal and product recall procedures. 3.9.1 All The company shall have a product recall procedure in place to effectively manage product withdrawals and recalls. Procedures shall exist to ensure that customers are notified immediately on issues of significance to the customer or consumer in terms of product safety, quality, or legality. 3.9.2 All The company shall have written agreements in place with distributors and other parties in the supply chain where these are necessary to ensure effective withdrawal/recall. 3.9.3 All In the event of a product recall, the certification body issuing the current certificate and the appropriate enforcement authorities shall be informed in a timely manner. The company shall be aware of and adhere to any legal reporting obligations in the countries of sale. 3.9.4 1&2 3.9.5 1&2 3.10 Statement of Intent CP030 Released 1/8/2012 The product recall and withdrawal procedures shall be documented and regularly tested, at least annually, in a way that ensures their effective operation. Results of the test shall include timings of key activities and shall be retained. The company's senior management shall ensure that results of this test shall be used to implement improvements as necessary? Management of incidents and business continuity The company shall have procedures in place to identify methods of ensuring business continuity in the case of incidents and/or informing their customers when incidents occur. Self-Assessment Tool Page13 3.10.1 All 3.10.2 1&2 3.10.3 1&2 The procedures shall include as a minimum: identification of key staff constituting the incident management team and their key responsibilities; an up-to-date list of key contacts, with details of agencies providing advice and support. Contract review and customer focus Statement of Intent The company's senior management shall ensure that processes are in place to determine any customer requirements and expectations with regard to product safety and quality, and ensure that these are fulfilled. Customer requirements shall be documented, reviewed, and confirmed on a suitable predetermined frequency. Any resulting changes shall be documented and communicated to relevant departments. 3.11 The company shall provide written guidance to relevant staff regarding the type of event that would constitute an incident or emergency situation that impacts product safety, legality, or quality, and a documented reporting procedure shall be in place which shall include informing their customers in a timely manner. The company shall develop contingency planning for business continuity in the event of major incidents such as: disruption to key services - e.g. water, energy, staff availability; events such as flood, fire, or natural disaster; malicious contamination or sabotage. 3.11.1 All 3.11.2 All In the case where customers have set particular performance indicators to be monitored, these requirements shall be communicated, adhered to, and reviewed at least annually. 3.11.3 1&2 3.11.4 1&2 The company shall clearly identify those individuals responsible for communication with customers and shall have an effective system for communication. Performance indicators relating to customer satisfaction shall be established and communicated to relevant staff, and performance reviewed against these targets. Complaint handling 3.12 Statement of Intent CP030 Released 1/8/2012 The company shall operate an effective system for the capture, recording, and investigation of product complaints. Self-Assessment Tool Page14 3.12.1 All A system shall be in place to capture, record, and investigate all complaints relating to product safety, legality, and unusual or critical quality defects, and the results of the investigation shall be recorded. 3.12.2 All Where complaints are investigated externally on behalf of the company, the responsibilities of the parties shall be defined and the process shall be documented. Companies shall seek to obtain the results of any investigations carried out by such parties. 3.12.3 All 3.12.4 1&2 Actions appropriate to the seriousness and frequency of the problems identified shall be carried out promptly and effectively by trained staff. Complaint data shall be analyzed and used to implement ongoing improvements to product safety, legality, and quality, and to avoid recurrence. This analysis shall be made available to relevant staff. Site Standards Section 4 4.1 Location, Perimeter and Grounds Statement of Intent 4.1.1 All 4.1.2 All 4.1.3 4.1.4 All All 4.1.5 All 4.2 CP030 Released 1/8/2012 Sites used for manufacturing, storage or distribution shall be of suitable size, location, construction and design to facilitate maintenance, prevent contamination, and enable the production of safe and legal products. The site to be included in the audit shall be clearly defined, and shall be located and maintained so as to allow the production of safe and legal products. Consideration shall be given to local activities and the site environment, which may have an adverse impact on product integrity. Measures adopted at the site to protect the product from any potential contaminants shall be regularly reviewed to ensure that they continue to be effective. The external areas and surroundings shall be maintained in good order. External traffic routes that are under site control shall be maintained in good repair to avoid contamination of the product. There shall be no evidence of facility damage due to inadequate drainage. Internal Site: Factory layout, Product Flow and Segregation Self-Assessment Tool Page15 Fundamental Clause 4.2.1 All 4.2.2 All 4.2.3 4.2.4 All All 4.2.5 All 4.2.6 1&2 4.3 Statement of Intent 4.3.1 CP030 Released 1/8/2012 All Premises and plant shall be suitably designed, constructed, and maintained so as to control the risk of product contamination and to comply with all relevant legislation. The building shall be maintained to minimize potential for product contamination. The machinery and equipment shall be positioned to allow an efficient product flow from incoming to outgoing and shall be arranged to minimize the risk of product contamination and damage. A process flow diagram shall be available. Premises shall allow sufficient working space and storage capacity to enable all operations to be carried out under safe and, if necessary, hygienic conditions. There shall be effective segregation to minimize the risk of product crosscontamination taking into account the flow of product, nature of materials, equipment, personnel, waste, airflow, air quality, and utilities. When critical to product safety, legality, quality, or customer requirements, controls shall be in place to ensure that raw materials, work in progress, rework, packaging, and finished products of different specifications are not inadvertently mixed. The location of facilities and services, including toilets, cleaning facilities, and catering facilities, shall not jeopardize the integrity of the product. Building interiors The internal site, buildings, and facilities shall be suitable for the intended purpose. All utilities to and within the production and storage areas shall be designed, constructed, maintained, and monitored to effectively control the risk of product contamination. The quality and finish of site buildings and facilities, including drainage when required, shall be suitable for the intended purpose with due regard to the risk of product safety, legality, and quality, and shall be maintained to an appropriate standard. This shall include: A clean, tidy and clutter-free factory; adequate lighting; suitable and sufficient removal of any byproducts and contaminants; impervious floors, in good repair, and able to withstand cleaning procedures. Self-Assessment Tool Page16 4.3.2 1&2 4.3.3 1&2 4.3.4 1 Walls, floors, ceilings, pipework, and overhead structures shall be designed, constructed, finished, and maintained to reduce condensation and mold growth, and shall have access to facilitate cleaning. 4.3.5 1 All water used as an ingredient of the products or preparation of the products where it may come into direct contact with the product shall be potable (as defined in the region of intended product sale), or suitably treated to prevent contamination, and shall be regularly monitored. 4.3.6 1 Water in the form of water, ice, or steam used for cleaning or in connection with any operation in the manufacture of products shall comply with legal requirements in the country of use and present no risk to the safety, legality, or quality of the products. 4.4 Staff Facilities Statement of Intent 4.4.1 All 4.4.2 1&2 4.4.3 1&2 CP030 Released 1/8/2012 Potential contamination risk from buildings and overhead structures, including building voids, shall be controlled through regular documented inspections, and corrective action shall be taken to prevent the risk of production contamination. The site shall be assessed for any particular requirements relevant to the products being produced, such as temperature, humidity, electrostatic discharge. Any identified requirements shall be adopted, documented, monitored, and regularly reviewed. Staff facilities shall be sufficient to accommodate the required number of personnel, and shall be designed and operated to minimize the risk of product contamination. Such facilities shall be maintained in good and clean condition. Staff facilities such as washrooms, canteens, and break areas shall be designed and operated so as to minimize the risk of product contamination. Where smoking is allowed under national law, designated controlled smoking areas shall be isolated from production areas to an extent that ensures smoke cannot reach the product. Adequate arrangements for dealing with smokers' waste shall be provided both internally and externally. Storage facilities of sufficient size to accommodate all reasonable personal items shall be provided for all personnel who work in areas where they are unable to keep possessions with them. Self-Assessment Tool Page17 4.4.4 1 Where specific workwear is required, designated changing facilities shall be provided for all personnel: staff, visitor, or contractor. These shall be sited to allow direct access to the production, packing, or storage areas without recourse to any external area. Where this is not possible, a risk assessment shall be carried out and procedures implemented accordingly. 4.4.5 1 4.4.6 1 Outdoor clothing and other personal items shall be stored separately from workwear within the changing facilities. Suitable and sufficient hand-cleaning facilities shall be provided at access to, and at other appropriate points within, production areas. Information on how to clean hands shall also be provided near hand-cleaning points. 4.4.7 1 4.5 Cleaning procedures Fundamental Clause 4.5.1 All 4.5.2 All 4.5.3 All 4.5.4 All CP030 Released 1/8/2012 All food brought into manufacturing premises by staff shall be stored in a clean and hygienic state. No food shall be taken into storage, processing, or production areas. Housekeeping and cleaning systems shall be in place which ensure that adequate standards of cleanliness and tidiness are maintained at all times and the risk of contamination is minimized. Cleaning practices shall be completed so as to minimize risk of contamination. Cleaning and, where necessary, disinfection procedures shall be revalidated following building or maintenance work, changes to equipment, or introduction of new product types. Cleaning, pest control, and process-aid chemicals shall be suitably identified and controlled to prevent the risk of product contamination. They must be clearly labelled and no chemicals shall be decanted unless into properly labelled and identified containers. Adequate storage facilities shall be provided and sited so as not to compromise the safety, legality, and quality of the product. If cleaning services are outsourced, the service providers shall have signed a contract which identifies the scope and frequency of the work, and a logbook shall be maintained as a record of work done. A defined company representative shall be responsible for ensuring that the work is carried out satisfactorily. Self-Assessment Tool Page18 4.5.5 1&2 4.5.6 1&2 4.5.7 1 4.6 Waste/Waste disposal Statement of Intent 4.6.1 All 4.6.2 All 4.6.3 All 4.6.4 All 4.6.5 All 4.7 CP030 Released 1/8/2012 Documented cleaning procedures shall be in place and maintained for the building, utilities, plant, and all equipment. Cleaning procedures shall included the following information as a minimum: responsibility for cleaning; item/area to be cleaned; frequency of cleaning; method of cleaning; cleaning materials to be used; cleaning records and responsibility for verification. Cleaning and housekeeping shall be carried out by trained personnel in accordance with documented procedures, and records shall be maintained. The effectiveness of cleaning and sanitation shall be verified and documented. Corrective actions shall be documented. Cleaning procedures shall be revalidated following building work, maintenance, changes to equipment or new product introduction. There shall be adequate systems for the collection, collation, and disposal of waste material. Systems shall be in place to prevent the accumulation of waste in production areas, and to prevent the use of unfit or defective materials. Waste shall be categorized according to legislative requirements based on the intended means of disposal, segregated if necessary, and collected in suitably designated waste containers. Where legally necessary, it shall be removed by identified, licensed contractors, and records of disposal shall be maintained by the company. Products which are to be disposed of on safety grounds, as the result of a recall or withdrawal, or as substandard trademarked materials, shall be disposed of securely. This may be delegated to a specialist in secure waste disposal. Records of such material destruction or disposal shall be maintained. Waste materials shall be suitably quarantined and routed to ensure that they are not reintroduced into non waste production flows. External waste collection containers and compactors shall be managed in such a manner as to minimize risk to the product if necessary. Pest control Self-Assessment Tool Page19 Statement of Intent The company shall be responsible for minimizing the risk of pest infestation on the site. The company shall be responsible for identifying and controlling the risk of pest infestation and shall operate pest control procedures. If no pest control is conducted the company shall have a full justification for its absence, including its customers’ acceptance. The justification shall be reviewed at least annually. (NOTE: If there is a justified absence of pest control then the other clauses in this section are not applicable) 4.7.1 All 4.7.2 All 4.7.3 All 4.7.4 All In the event of infestation, immediate action shall be taken to eliminate the hazard and this shall be documented. Action shall be taken to identify, evaluate, and authorize the release of any product potentially affected. 4.7.5 All 4.7.6 All Full material safety data sheets (MSDS) for all chemical pest control agents used must be available to relevant staff at all times and kept in a designated place. Bait stations shall be robustly constructed, operational, and effective in killing the target pests, and be positioned to avoid potential contamination of materials and products. 4.7.7 All When necessary, materials or products shall be fumigated, and records of this process shall be kept. Fumigated goods may not be supplied to customers without full professional safety clearance and correct clearance documentation. All fumigation operations shall be controlled by staff with appropriate professional qualifications. 4.7.8 4.7.9 1 1 Drains should be fitted with screens and traps to prevent pest entry. Fly-killing devices and/or pheromone traps shall be correctly sited and be operational. The design and location of flying insect detectors, killers, and traps used shall not cause contamination of products in production. 4.7.10 1 4.8 Bait stations shall be tamper resistant. Product transport, storage and distribution CP030 Released 1/8/2012 Self-Assessment Tool Page20 The company shall either have a clearly defined contract with external contractors which reflects the activities of the site, or have trained staff. Written procedures and inspection documentation for pest control shall be maintained including a logbook of work completed. Statement of Intent All facilities used for the storage and transportation of product, movement around the site, and dispatch of finished product shall be suitable for the purpose and maintained in good repair. 4.8.1 All The company shall ensure that the transport and storage of products is within its control, from delivery of raw materials and components to finished product. Dispatch shall be undertaken in such a way as to prevent the risk of contamination and damage. 4.8.2 All 4.8.3 All 4.8.4 All 4.8.5 All Where storage is necessary, at any stage, all items shall be securely protected from contamination, deterioration, and damage. All transportation shall be in good repair and in a clean/hygienic condition as necessary depending on the product group. Where the product transported is susceptible to weather damage, vehicles shall be loaded and unloaded so as to protect the product. Where the product needs specific environmental requirements to prevent degradation, the appropriate conditions shall be documented, maintained, and monitored. 4.8.6 All When products are susceptible to hazards arising from transport conditions or subject to transport restrictions, the required conditions of transport shall be documented, implemented, and subject to regular review. Any necessary product labelling shall be documented and monitored. 4.8.7 All Where the company employs third-party contractors, there shall be an agreement between the company and the contractor. All the requirements specified in this section shall be clearly defined in the contract. 4.9 Site Security Statement of Intent 4.9.1 All 4.9.2 All CP030 Released 1/8/2012 Security shall be maintained to prevent access of unauthorized persons to production and storage areas. Access to the site by employees, contractors, and visitors shall be controlled and a visitor-reporting system shall be in place. Contractors involved in maintenance or repair shall be qualified or supervised, and a nominated staff member shall be responsible for their activities with regard to potential effects on the safety, legality, or quality of products. Self-Assessment Tool Page21 4.9.3 1&2 Staff shall be trained in site security procedures and encouraged to question or report unidentified or unknown visitors. Product Control Section 5 5.1 Preproduction reference samples Statement of Intent 5.1.1 All 5.1.2 All 5.1.3 All 5.1.4 All 5.1.5 All 5.1.6 All 5.2 CP030 Released 1/8/2012 Documented procedures shall be in place for the selection, handling, storage, approval, and use of reference samples as well as for component samples and samples of subcontracted work where relevant. The company shall document a process to identify, select, and categorize reference samples. If customers have a defined system of sealed samples referring to different stages of sample approval, the customer procedure shall be documented and followed. As a minimum, a sample of the product which has been approved by the customer or, if customer approval is not possible, a sample representative of the agreed specification, shall be retained. Procedures shall be in place to record the selection, use, approval, and storage of reference and/or component samples. Reference samples shall be held and stored in suitable environmental conditions to maintain their original status. A secure and tamper-evident system shall be in place for the storage of samples. Temporary removal of samples must be documented and authorized by a designated responsible person. Records shall be maintained of reference samples supplied to other parties, including the date supplied and details of the sample. Exceptions to the need to store samples shall be made when such storage is impractical, provided that an alternate means of achieving the same objective is documented, justified, and maintained. Chemical formulation control Self-Assessment Tool Page22 Statement of Intent The chemical composition of products and chemicals used in the manufacture or processing of products shall be identified, monitored, and recorded as required by legislation in the country of sale and/or manufacture. Where approvals for use need to be obtained, these shall be in place. 5.2.1 All Where companies use materials or preparations for which the supplier does not wish to divulge confidential formulations, they must have a procedure in place to ensure the safety and legality of such materials (for example, through an independent third-party review) and must assure themselves that any information which may be legally required will be made available to the authorities in a timely fashion. 5.2.2 All Companies shall review, document, and justify the use of any substances classified as dangerous or of very high concern in the country of sale. 5.2.3 All Written (and/or diagrammatic), authorized procedures for the handling of chemicals shall be available at the point of use. 5.2.4 1&2 5.3 Statement of Intent 5.3.1 All 5.3.2 All 5.3.3 All 5.3.4 All CP030 Released 1/8/2012 Companies shall identify and document the use of any nanomaterials. Product packaging materials Product packaging materials shall be suitable for the intended use and stored under conditions to minimize the risk of contamination and deterioration. Product packaging shall conform to an agreed and documented specification and shall meet the legal requirements of the regions of sale with regard to composition, recyclability, and minimizing excessive use of packaging material. Packaging shall be assessed for fitness for purpose and found suitable with regard to: protecting the product from damage; maintaining the integrity of the product; protecting the consumer from injury; preventing contamination. Packaging materials shall be effectively protected before being returned to storage. Where staples or other metal closures are used for packaging, appropriate precautions shall be taken to prevent the risk of contamination, damage, or injury to the product or consumer. Self-Assessment Tool Page23 5.3.5 1 5.4 Where there is a risk of product contamination from transit packaging that could compromise product safety, legality, and quality, such packaging shall be removed from production areas. Control on nonconforming materials Statement of Intent 5.4.1 All 5.4.2 All 5.5 Statement of Intent The company shall ensure that nonconforming materials, components, and products are clearly identified, labeled, quarantined, investigated, and documented. Clear procedures for the control of nonconforming materials and products, including rejection, segregation, acceptance by concession, or re-grading for an alternate use, shall be in place and understood by all authorized personnel. The company shall have a procedure in place for the secure disposal of nonconforming products and their packaging according to the nature of the problem and/or the specific requirements of the customer and any legal requirements. Handling requirements for specific materials Where materials or products require special handling procedures to be in place, these shall be maintained to ensure product safety, quality, and legality are not compromised. 5.5.1 All 5.5.2 1&2 The company shall determine whether allergenic or sensitizing materials are used (or likely to be contaminants of materials used) and shall identify any such materials used on site. 5.5.3 1&2 Documented policies shall exist for the handling of allergenic or sensitizing materials including: physical or time segregation from other products; use of identified, dedicated equipment if necessary; adequate labelling of final products. Stock Control and product release 5.6 CP030 Released 1/8/2012 Materials and products requiring segregation procedures (e.g., materials intended for different geographical regions) shall have control procedures in place to ensure that product integrity is maintained. Self-Assessment Tool Page24 Statement of Intent The company shall ensure that the finished product is not released unless all agreed procedures have been followed and the release is suitably controlled. 5.6.1 All A procedure shall be in place to ensure that only products conforming to specification are dispatched. If no such control is conducted, the company shall have a full justification for its absence, which shall be reviewed at least annually. Procedures may include, but are not limited to: positive final release by authorized staff; online test methods; automatic rejection process (which must be validated and monitored). 5.6.2 All 5.6.3 1&2 Companies shall ensure that work carried out by homeworkers or subcontracted off-site shall be included in procedures described in clause 5.6.1. Controls shall be in place to ensure correct stock rotation and that materials and products are used in the correct order and within the allocated shelf or usage life if applicable. 5.6.4 1&2 Section 6 6.1 Fundamental Clause CP030 Released 1/8/2012 Procedures shall be in place for disposal of excess stock or obsolete inventory where such situations routinely occur. If such disposal is an isolated instance, measures taken shall be documented. Product Conformity Assessment Product Analysis/Testing A suitable, sufficient, and validated testing regime shall be in place to ensure the safe, legal production of products to the required conformance of safety, legality, and quality. Results from the program shall be recorded, reviewed, and stored securely. Self-Assessment Tool Page25 6.1.1 All 6.1.2 All 6.1.3 All 6.1.4 All Testing shall be undertaken by the company, the subcontractor, a competent third party, a laboratory designated by government authorities, or the customer’s designated testing laboratories, as agreed. 6.1.5 All For tests which are critical to product safety or legality, the laboratory used shall have gained recognized laboratory accreditation against ISO 17025 for the tests to be carried out. If accredited facilities are not used, the laboratory conducting the tests must be able to provide verifiable evidence that it is complying with the requirements of ISO 17025. 6.1.6 All 6.1.7 All Procedures shall be in place to ensure the security of samples and test results. Where testing is submitted to third parties, the required testing shall be clearly defined including, for example, reference to the number, date, and version of the test standard or method to be used. In cases where the company relies on the expertise of third-party testing organizations to determine appropriate test requirements, the company shall ensure that the third party receives a clear written briefing on the purpose of the test and that the testing program is formally agreed and documented. CP030 Released 1/8/2012 Companies shall adopt a product-testing program based on information such as: the outcome of the risk assessment procedure including any defined control points; any legal requirements for testing in the regions(s) of intended sale; customer requirements regarding supply of test reports or other information; their own requirements for demonstrating the production of safe products; information needed to confirm composition of materials; historical data on problems or complaints. In cases where it is established that no testing is required, this shall be justified, documented, and reviewed at least annually. (Note: If there is a justified absence of testing then the other clauses in this section are not applicable.) The company shall identify the different stages (for example, preproduction, production) at which testing is to be performed. A documented sampling plan, testing program, and test specification, including the pass or fail criteria, shall be produced for each product or product type as required. Testing procedures carried out as a result of a complaint, product failure, or other ad hoc reason shall be clearly documented. Self-Assessment Tool Page26 6.1.8 All For tests other than those specified in clause 6.1.5, procedures shall be in place to ensure validity of all test results: use of documented, validated test methods; use of correctly calibrated and maintained test equipment; incorporation of quality control checks in the tests; use of systems such as proficiency testing to verify the accuracy of results where available; use of suitably qualified and/or trained staff, competent to carry out the analyses required. 6.1.9 All Test results which are outside the defined specification shall be reviewed in a timely manner by the nominated person responsible for safety, legality, and quality, and the need for corrective action assessed, documented, and carried out as necessary. 6.1.10 1&2 6.2 Inspections Statement of Intent 6.2.1 CP030 Released 1/8/2012 Where testing laboratories are present on a manufacturing site, they shall be located, designed, and operated to eliminate potential risks to product safety. Controls shall be documented, implemented, and shall include consideration of the following: design and operation of drainage and ventilation systems; access to and security of the facility; movement of laboratory personnel; protective clothing arrangements; processes for obtaining product samples; disposal of laboratory waste. All When product inspections are deemed necessary to assure delivery of a safe, legal product of the required quality, they should be carried out following defined procedures that are documented, reviewed, and authorized. Companies shall assess the need for product inspections, which, if required, shall have a defined purpose and operate to a defined list of parameters to be examined, with defects and defect types clearly identified. In cases where it is established that no inspections are necessary, this shall be justified, documented, and reviewed at least annually. (Note: If so, then the other clauses in this section are not applicable.) Self-Assessment Tool Page27 6.2.2 All Sampling procedures shall be defined, documented, and justifiable. The appropriateness must be demonstrable and based on considerations of risk, type of product, inspection frequency, statistical rationale, etc. 6.2.3 All Sampling plans, where required, shall be documented and approved and reviewed when changes in production methods or materials occur. They shall include as a minimum: the sample size to be taken; the acceptance/rejection criteria; defined acceptable quality limit (AQL); the defect classification; the actions to be taken in the case of rejection. 6.2.4 All 6.2.5 All Inspections shall be conducted at a level and/or frequency to assure product quality is at an AQL level that is acceptable to the customer. The company shall have a defined policy and procedure covering the handling of inspected goods; for example: policy on returning inspected goods to production; repacking requirements; disposal. 6.2.6 All Procedures shall be in place to ensure inspections are carried out in suitable conditions and with sufficient space and lighting to avoid the introduction of hazards into the products. 6.2.7 All 6.2.8 All Personnel undertaking inspections shall be suitably qualified and/or trained, and shall be competent to carry out the work required. When external contractors are used for inspections, they shall be subjected to the usual supplier/subcontractor approval processes. 6.2.9 All Product claims 6.3 Statement of Intent 6.3.1 CP030 Released 1/8/2012 Inspection results which are outside the defined acceptance level shall be reviewed in a timely manner by a competent person and the need for corrective action assessed, documented, and completed. All The company shall have procedures in place to validate and declared product information or claims made for the products and monitor compliance with such claims if necessary. Where necessary the company shall operate a quantity control system which conforms to legal requirements and/or specified customer requirement in the region where the product is available for sale. Self-Assessment Tool Page28 6.3.2 All 6.3.3 All 6.3.4 1&2 Where quantity checking is required, the frequency and methodology used shall meet the minimum requirements of any legislation governing quantity verification. Any claims about a product, e.g., a weight limit for a trampoline or sun protection factor on a cream, shall be fully validated to ensure that products meet the stated claim. The company shall undertake product-in-use evaluations, testing and/or reliability trials, and/or shelf-life evaluations to validate and verify that production of a safe and legal product is maintained, taking account of the category of consumers at risk. Process Control Section 7 7.1 Control of operations Fundamental Clause 7.1.1 All 7.1.2 All 7.1.3 All 7.1.4 All 7.1.5 All 7.1.6 1&2 CP030 Released 1/8/2012 The company shall be able to demonstrate effective control of all operations undertaken, to ensure product safety, legality, and quality and ensure that the processes and equipment employed are capable of producing consistently safe and legal product with the desired quality characteristics. The company shall conduct a risk assessment of hazards potentially introduced during the production, packaging, or storage processes. The company shall establish precise process flow(s) established and a control plan which identifies the critical control points (if any), control limits, monitoring points and the records required. The company shall define how changes to the control plan are approved and implemented. Preproduction meetings shall be conducted prior to new or substantially changed products being produced, to evaluate and approve the processes. Process monitoring shall be established and adequately controlled to ensure products are produced within the required process specification. Corrective action shall be taken in the event of deviation of the process from specification. This shall be recorded. The company shall have a fully implemented and maintained process risk assessment system, based on established principles. Self-Assessment Tool Page29 7.1.7 1&2 7.2 In circumstances where process parameters are controlled by in-line monitoring devices, these shall be linked to a suitable failure alert system and routinely tested. Control of incoming components and raw materials Fundamental Clause 7.2.1 All 7.2.2 All 7.2.3 All 7.3 The company shall have procedures to specify, validate, and approve incoming materials, which shall include any testing, inspection, or review of certificates of analysis. Raw materials or components critical to product safety, legality, or quality shall have documented approval procedures to assure conformance to agreed specifications and requirements and documented positive batch release. The requirement for documented approval procedures as described in clause 7.2.1 shall also apply to subcontracted work or work performed outside the site being audited. The company shall have a documented procedure to ensure that materials or components used by homeworkers (when used) are approved. (See also homeworker requirements in clause 5.6.2) Equipment & equipment maintenance Statement of Intent Equipment shall be suitably designed for the intended purpose and shall be maintained and used so as to minimize the risk to product safety, legality, and quality. 7.3.1 All All equipment shall be properly specified before commission, and operating parameters for production equipment and tooling shall be determined, validated, and implemented as part of the control plan. Validation records pertinent to safety or legality shall be kept for the lifetime of the equipment. 7.3.2 All In the case of equipment failure or deviation of the process from specification, procedures shall be in place to establish the safety status of the product prior to release. CP030 Released 1/8/2012 Self-Assessment Tool Page30 7.3.3 All A documented system of planned maintenance shall be in place, covering all items of equipment and plant which are critical to product safety, legality, and quality. This shall include, but not be limited to, records of: periodic maintenance schedules and completion; preventative maintenance; required safety checks; spare-parts listings and replacements; contingency plans for failure of essential equipment. 7.3.4 All 7.3.5 All Materials (for example, lubricating oils and paints) used for equipment and plant maintenance shall be assessed to establish whether they pose a risk by direct or indirect contact with raw materials, intermediate products, and finished products. If necessary, they shall be suitably identified for the intended use and controlled. Engineering workshops shall be controlled to prevent contamination risks to the product and be organized, clean, and tidy to allow safe, efficient, and good-quality work. 7.3.6 All 7.3.7 1&2 7.3.8 1 Certificates of conformity or other evidence to confirm suitability for use shall be available for equipment in direct contact with products, raw materials, and work in process. 7.3.9 1 On completion of any maintenance work, machinery and equipment shall be clean and free from contamination hazards. A documented hygiene clearance procedure shall exist. 7.4 Foreign body detection and control Statement of Intent 7.4.1 CP030 Released 1/8/2012 When possible, equipment shall be positioned so as to give access beneath, inside, and around it for ease of cleaning and servicing. In addition to any planned maintenance program, where there is a risk of product contamination by foreign bodies arising from equipment failure, the equipment shall be inspected at predetermined intervals, inspection results documented, and any necessary corrective action taken. All Where deemed necessary by the documented risk assessment, the company shall have systems for foreign-body detection in place to ensure its effective operation. The company shall ensure that all necessary steps are taken to identify and prevent the risks of foreign-body contamination as identified by risk assessment. This shall include any contamination potentially introduced by the packaging. Self-Assessment Tool Page31 7.4.2 All Tools and other sharp objects used in production shall be controlled. Methods such as, but not limited to, the following may be used: snap-offblade knives prohibited; tools permanently attached to benches; items controlled by a listing and registration procedure; needle policy where all parts of broken needles have to be returned prior to new issue. 7.4.3 All Where a metal or foreign-body detector is required or specified by the customer, the company shall establish documented procedures specifying its use, location, critical limits for detection, and recording of results. 7.4.4 1&2 Except when used as part of the product, the presence and location of all glass, ceramic, and brittle-plastic material in raw material handling, preparation, processing, and packing and storage areas shall be listed in a register. Checks of the condition of these materials should be carried out at a specified frequency and the results recorded. 7.4.5 1&2 Where they constitute a risk to the product, a management system that shall include written procedures shall be in place for all glass, brittle plastics, and ceramics to ensure the necessary precautions are taken. Breakages shall be recorded and records retained. 7.4.6 1 7.5 Statement of Intent 7.5.1 All 7.5.2 All CP030 Released 1/8/2012 Except when used in the product, the use of wood within raw-material handling, preparation, processing, packing, and storage areas shall be eliminated except for wooden pallets, where any risks should be evaluated and controlled. Calibration and control of measuring and monitoring devices Measuring equipment used to monitor product safety, quality, and legality shall be identified. The identified measuring equipment shall be calibrated to a recognized national or international standard. Where a traceable calibration is not possible, the company shall verify the basis by which calibration is declared. The company shall identify equipment used to make measurements relevant to product safety, legality, and quality. The equipment used in accept-or-reject activity shall be calibrated to a specified accuracy and precision at a defined frequency (or before use). Self-Assessment Tool Page32 7.5.3 All The calibration of identified equipment shall be traceable to a recognized national standard. Where such a standard does not exist, the basis by which calibration is declared shall be verified. 7.5.4 All Records of the results of calibration and verification shall be maintained for a suitable period, taking account of the life of the products being produced. 7.5.5 All 7.5.6 All 7.5.7 All Identified equipment shall be prevented from being adjusted by unauthorized staff and shall be marked to show the calibration status and period of validity. The company shall define suitable test pieces and operate a defined monitoring and testing procedure to identify any failure of metal/foreign body detectors (if used). Procedures shall be in place for actions to be taken if equipment is found not to be operating within specified tolerances and/or limits. Retained production samples 7.6 Statement of Intent 7.6.1 All 7.6.2 All 7.6.3 All 7.7 Statement of Intent CP030 Released 1/8/2012 The company shall ensure the adequate and secure retention of production samples to assist in the investigation of complaints and to verify that production is in conformity with the agreed specification. The company shall retain a fully representative production sample of each product as received by the customer (including the packaging). Exceptions may be made for products that are impractical to store, provided the information usually provided by a production sample can still be identified. A designated person shall authorize retained production samples and/or component samples (see also requirements in 5.1 'Preproduction reference samples'). Procedures shall be in place to determine the retention time of retained samples. This should normally be the foreseeable lifetime of the product unless otherwise justified. Retained samples shall be securely held and stored in suitable conditions to maintain their original status. Final product packing and control The company shall establish a procedure for the packing of products to ensure that products are supplied which meet relevant safety criteria, taking account of legal requirements and customers' specific Self-Assessment Tool Page33 requirements. 7.7.1 All The company shall define and validate the packing procedure for products taking particular account of customer requirements. That shall include methods of ensuring that the correct product(s) and components are correctly packaged with and placed in the correct outer packaging. 7.7.2 All Quantity markings on the product or pack should be accurate, verified, and in accordance with the legal requirements in the country of sale. 7.7.3 All The company shall verify that information shown on primary (consumer) package labels and outer cartons is correct and meets the regulatory and safety requirements of the region of intended sale. Personnel Section 8 8.1 Training and competency Fundamental Clause The company shall ensure that personnel performing work that affects product safety, legality, and quality are demonstrably competent to carry out their activity, through training, work experience, or qualification. 8.1.1 All The company shall ensure that all employees are able to demonstrate competence with regards to their activity. The company shall: identify the need for training; document training procedures and records to demonstrate that training is effective and regularly reviewed; ensure that training includes both general information on the company and specific job training. 8.1.2 All Employees having direct effect on the safety, quality, or legality of products shall be trained to ensure understanding of risk assessment procedures or outcomes as necessary for their activity. Those conducting or participating in risk assessments shall be adequately trained in risk assessment methods. CP030 Released 1/8/2012 Self-Assessment Tool Page34 8.1.3 All 8.2 Protective clothing Statement of Intent 8.2.1 All 8.2.2 1&2 8.2.3 1&2 8.2.4 1&2 8.3 Statement of Intent 8.3.1 1&2 8.3.2 1&2 8.3.3 1 8.3.4 1 8.3.5 1 8.3.6 1 CP030 Released 1/8/2012 Training records should be stored such that privacy of personnel is protected and legal compliance with data protection laws in the country of operation are respected whilst also allowing auditors access to necessary information. Training shall be traceable to an individual employee. The company's standards shall be documented and adopted by all personnel, including contractors and visitors to the production facility. Where a need for protective clothing has been identified by the risk assessment, this shall not pose a contamination risk to the product. Based on the assessment of risk to the product, suitable footwear shall be worn within the factory environment if necessary. Protective clothing, where provided, shall be effectively laundered at an appropriate frequency. Disposable protective clothing, if used, shall be subject to adequate control to avoid product contamination. Hygiene practices Standards of hygiene shall be formulated with due regard to the risk of product contamination. Where metal foreign-body detection is in place, detectable plasters shall be used and shall be regularly tested through the detector. The company shall have a policy to control the wearing of jewellery so that it poses no risk of product contamination. All cuts and grazes on exposed skin shall be covered by contrasting coloured plasters that are company issued and monitored. Hand-cleaning shall be performed at a suitable frequency to maintain hygienic conditions. No eating, drinking, or smoking shall be permitted within production or packaging areas. All head and facial hair shall be fully contained to prevent product contamination. Self-Assessment Tool Page35 8.3.7 1 The company shall be vigilant concerning employees, including temporary employees, when they may be suffering from or have been in contact with any relevant infectious disease or condition. The company should have a procedure for the notification by employees where this is legally allowable. 8.3.8 1 Where the company becomes aware of a person who has entered the premises suffering from a relevant infectious disease, steps shall be taken to minimize any risk to product safety. 8.3.9 1 Where there may be risk to product safety, and where legally allowable, visitors and contractors shall be required to complete a health questionnaire prior to entering the raw-material, preparation, processing, packing, and storage areas. If necessary, these persons shall undergo medical screening before permission is granted to enter the raw-material, preparation, processing, packing, and storage areas. 8.3.10 1 Fingernails shall be kept short, clean, and unpolished. False fingernails are not permitted. CP030 Released 1/8/2012 Self-Assessment Tool Page36 Product Group Decision Tree - Manufacturer Is this product defined as a pharmaceutical or cosmetic. Is it used invasively* or contain nanomaterials? Product Group 1 Does the product have product specific legislation requiring hygienic manufacture (e.g. GMP)? Product Group 1 Is there potential for contamination of the product which could cause major injury* or harm? Biological Radiation Product Group 1 Chemical Physical Product Group 2 Does the product have any product specific legal requirements concerning safety or harmonised* or mandatory* standards? Product Group 2 Does the product require risk or safety warning on the product packaging, labeling or instructions? Product Group 2 Is the product on contact with skin* during foreseeable use? Is the product subject to mandatory labelling of ingredients or components Product Group 2 Can this product type cause death or major injury* if it fails during foreseeable use? Physical, Chemical, Electrical, Flammability, Magnetism, Acoustics, Radiation Product Group 2 Is the product designed or clearly intended for vulnerable* or very vulnerable* user groups? Product Group 2 Product Group 3 Product Group Decision Tree – Assembly Packer