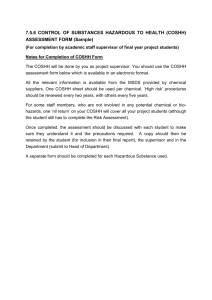

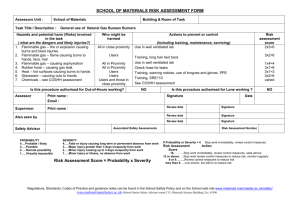

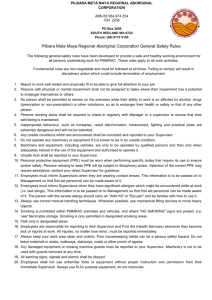

Health and Safety Policy

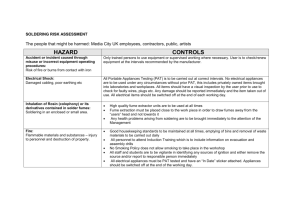

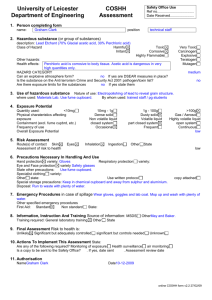

advertisement