State of Charge Adjustment

advertisement

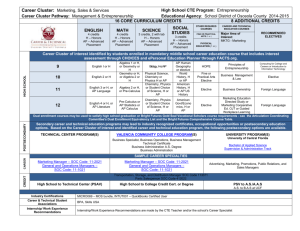

EVSTF-06-07e State of Charge Adjustment Preamble/Justification The EVS-GTR specifies test methodology for evaluating propulsion battery performance in vehicle crash tests and in various abuse conditions. In most of these tests, the performance criteria are that no fire or explosion shall occur. Li-ion based rechargeable electrical energy storage systems (REESSs) have demonstrated significantly decreased tolerance for abuse as state of charge (SOC) is increased. In regards to safety, selfpropagating thermal heating response is the most relevant failure mode and is strongly affected by the REESS SOC. As described in Figure 1, the peak heating rate of a cell in a thermal runaway event for REESS systems is stable at low SOC, but increases in a non-linear exponential rate as SOC nears 100%. Peak Heating Rate (W) 700 600 500 400 300 200 100 0 0 50 100 150 State of Charge (%) Figure 1. Peak heating rate (W) versus state of charge (Data acquired from 16 Ah production level pouch type LMO/NMC cells by Sandia National Laboratory for a NHTSA sponsored “Stranded Energy Project”) Experimental data shows that the onset temperature of thermal runaway of cells in a Li-ion based REESS is lower and enthalpy, and heat release rate in the event of a fault is greater at higher levels of SOC. For this reason, standardizing the SOC during safety testing is critical for relevant, reliable and repeatable test responses. Generally, Li-ion based REESS in electric vehicles operate in the stable range of SOC (where peak heating rates are low). However, there could be REESS designs with cells operating at higher range of SOC to increase energy capacity. Ideally, all testing should be conducted at the maximum SOC under normal use as specified by the manufacturer to fully evaluate the safety implications of the test. However, due to practical limitations for conducting the test, batteries and battery electric vehicles may have to be tested at a lower SOC. Though NHTSA recognizes that open circuit voltage is not a direct measure of SOC in Li-ion based REESS, for NHTSA’s crash tests of electric vehicles (EVs) and plug in hybrid electric vehicles (PHEVs); prior to testing the agency sought input from the manufacturer on the voltage at maximum SOC under normal use or the range of normal operating voltage. Table 1 shows the open circuit battery voltage measured following a completed charge cycle as specified under normal use by the manufacturer and the measured voltage at the time of conducting the crash test. These tests were conducted in 2011-2012 and no attempt was made to maintain a certain level of SOC. Nevertheless, the drop in voltage at the time of conducting the test from the manufacturer’s specified voltage at maximum SOC is less than 5 %. Table 1: Voltage at maximum SOC under normal use, pre-test SOC, and percentage drop in voltage of EVs and PEVs crash tested under 2011-2013 NCAP. Vehicle 2013 Ford C-Max Energi SEL 2013 Ford C-Max Energi SEL 2013 Ford C-Max Energi SEL 2013 Nissan Leaf Body Style Engine Type Max SOC (OEM) V Pre-Test SOC V % drop in voltage 345 337.4 2.2 345 340.7 1.2 345 334.7 3.0 5-Dr Hatchback Gas-Plug-In Electric Hybrid Gas-Plug-In Electric Hybrid Gas-Plug-In Electric Hybrid Electric 400 393.8 1.6 2013 Nissan Leaf 5-Dr Hatchback Electric 400 393.9 1.5 2013 Nissan Leaf 5-Dr Hatchback 400 393.5 1.6 2013 Ford Fusion SE Energi 4-Dr Sedan 345 338.5 1.9 2013 Ford Fusion SE Energi 4-Dr Sedan 345 338.7 1.8 2013 Ford Fusion SE Energi 4-Dr Sedan 345 330.5 4.2 2012 Mitsubishi i-MiEV 5-Dr Hatchback Electric Gas-Plug-In Electric Hybrid Gas-Plug-In Electric Hybrid Gas-Plug-In Electric Hybrid Electric 360 359.4 0.2 2012 Mitsubishi i-MiEV 5-Dr Hatchback Electric 360 359.4 0.2 2012 Mitsubishi i-MiEV 5-Dr Hatchback Electric 360 357.7 0.6 2012 Ford Focus Electric 5-Dr Hatchback Electric 350 349.3 0.2 2012 Toyota RAV4 EV 5-Dr SUV Electric 386 380.2 1.5 2012 Chevrolet Volt 2012 Mitsubishi i-MiEV Hybrid 2012 Chevrolet Volt Hybrid 5-Dr Hatchback Electric 390 389 0.3 5-Dr Hatchback Electric 360 359 0.3 5-Dr Hatchback Electric 390 379.5 2.7 2011 Chevrolet Volt 5-Dr Hatchback Electric 390 389.1 0.2 2011 Nissan Leaf 5-Dr Hatchback Electric 400 387 3.3 5-Dr Hatchback 5-Dr Hatchback 5-Dr Hatchback Independent contracted testing laboratories which have conducted New Car Assessment Program testing for NHTSA have indicated the relative simplicity in attaining and maintaining SOC at 95% of the maximum SOC under normal use as specified by the manufacturer for electric vehicles (EVs) and plug in hybrid electric vehicles (PHEVs)by charging the vehicle just prior to testing. For this reason, NHTSA recommends that for a vehicle with a REESS designed to be externally charged, the SOC when the vehicle is tested should not be less than 95% of the maximum SOC under normal use as specified by the manufacturer. For vehicles with no external charging capability such as hybrid electric vehicles (HEVs) and hydrogen fuel cell vehicles (HFCVs), the adjustment of SOC immediately before the crash test will not be possible as the fuel will be replaced with non-flammable materials. Therefore, for vehicles with a REESS designed to be charged only by an energy source on the vehicle, we agree with the Task Force 6 recommendation that the SOC when the vehicle is tested shall be no less than 90% of the highest SOC achievable under normal operation of the vehicle (as specified by the manufacturer). For component tests of REESS of HEVs, it may not be possible to charge the REESS when outside the vehicle. Therefore, we agree with the Task Force 6 recommendation that the initial SOC of the REESS which cannot control SOC by itself shall be no less than 95% of the highest SOC which is achievable under normal operation of the vehicle and that the SOC when the REESS component test is conducted shall not be less than 90% of its initial SOC. For other REESSs, we agree with Task Force 6 that the SOC when the component test is conducted shall be no less than 95 % of the highest SOC in accordance with the procedure specified by the manufacturer for normal use. We understand that determining SOC is specific to the REESS and may be dependent on a number of measured parameters, including temperature, voltage, current, and method of charging. For some REESSs, there may not be a direct relationship between open circuit voltage and SOC and so it may not be possible to use OCV-SOC curves for determining SOC. As a result, the manufacturer may need to provide a method of reading SOC from the CAN bus or provide levels of measured parameters and associated tables to determine maximum SOC in normal use, and pre-test SOC. NHTSA recommends Task force 6 to consider the feasibility of a common/standard method of SOC calculation or CAN reporting for determining pre-test SOC. NHTSA does not agree with the Task Force 6 recommendation to specify a time limit for when the test should be conducted (48 hours from the time of initial SOC measurement). While this specified time period may not be sufficient to significantly reduce SOC in some vehicles, it may be long enough to significantly lower SOC values in others below the minimum threshold. Additionally, for vehicles that can maintain SOC above minimum threshold levels for a long period of time (greater than 48 hours), the specified testing time may be overly restrictive for conducting the test. Therefore, we recommend not specifying a time limit for conducting the test. Instead, we recommend obtaining information from the manufacturer to determine maximum SOC under normal use and pre-test SOC. A battery pack maximum SOC depends on various factors including temperature, and type of charging and therefore need to be specified. Experimental data from a 6 Ah Li-ion battery tested at C/5 rate (Figure 2) shows that for a temperature range between 10 oC and 30 oC (20 oC ± 10 oC), the variation in maximum capacity in ampere-hour (Ah) is ±5%.1 1 From a JRC document – Initial condition of SOC in EVS-GTR test procedures. Figure 2. Maximum capacity versus temperature for a 6Ah lithium ion battery tested at C/5 rate. In order to avoid discrepancies due to differences in SOC at different temperatures, we agree with JRC’s proposal to use a narrow temperature range for testing REESS while taking into consideration practicality of conducting the tests. Since vehicle crash tests are often conducted outdoors where control of ambient temperature is not possible, a reasonable temperature variation of ±10 oC is recommended. On the other hand, for component tests (which can be conducted under controlled environmental conditions), a narrower temperature range of ±5 oC is recommended. Therefore, we agree with the Task Force 6 recommendation for conducting SOC adjustment at an ambient temperature of 20 ± 10 °C for vehicle-based tests and 22 ± 5°C for component-based tests. We also agree with the Task Force 6 recommendation that where different charging procedures are possible, the REESS shall be charged using the procedure which yields the highest SOC. Based on the above evaluation, NHTSA offers the following changes to the regulatory text developed by Task Force 6 for consideration. II. TEXT OF REGULATION The paragraph 6.1.5.2.1., amend to read 6.1.5.1.2.1. The SOC of the REESS shall be adjusted in accordance with the paragraph 6.2.1.2.. Insert a new paragraph 6.2.1 6.2.1. General procedures Renumber former paragraphs 6.2.1. to 6.2.1.1. 6.2.1.1. Procedure for conducting a standard cycle Insert new paragraphs 6.2.1.2-6.2.1.2.3., to read 6.2.1.2. Procedures for SOC adjustment 6.2.1.2.1. The adjustment of SOC shall be conducted at an ambient temperature of 20 ± 10 °C for vehicle-based tests [and 22 ± 5°C for component-based tests.] 6.2.1.2.2. The SOC of the tested-device shall be adjusted according to one of the following procedures as applicable. Where different charging procedures are possible, the REESS shall be charged using the procedure which yields the highest SOC. (a) For a vehicle with a REESS designed to be externally charged, the REESS shall be charged to the highest SOC in accordance with the procedure specified by the manufacturer for normal use until the charging process is normally terminated. (b) For a vehicle with a REESS designed to be charged only by an energy source on the vehicle, the REESS shall be charged to the highest SOC which is achievable with normal operation of the vehicle. The manufacturer shall advise on the vehicle operation mode to achieve this SOC. (c) In case that the REESS or REESS sub-system is used as the testeddevice, the tested-device shall be charged to the highest SOC in accordance with the procedure specified by the manufacturer for normal use until the charging process is normally terminated. Procedures specified by the manufacturer for manufacturing, service or maintenance may be considered as appropriate if they achieve an equivalent SOC as for normal use. In case the tested-device does not control SOC by itself, the SOC shall be charged to not less than [95 %] of the maximum normal operating SOC defined by the manufacturer for the specific configuration of the tested-device. 6.2.1.2.3. 6.2.1.2.3 After the adjustment of the SOC according to paragraphs 6.2.1.2.1. and 6.2.1.2.2. above, the test shall be started within 48 hours subject to taking all reasonable and practical steps to ensure the initial SOC (i.e. the SOC achieved at the end of the adjustment according to the paragraphs 6.2.1.2.1. and 6.2.1.2.2. above) is maintained, otherwise an appropriate verification shall be made to confirm that the SOC is maintained not less than 90 % of the initial SOC e.g. by checking the voltage-drop and using the OCV-SOC curve of the REESS, etc. When the vehicle or REESS subsystem is tested, the SOC shall be no less than 95 % of the SOC according to paragraphs 6.2.1.2.1. and 6.2.1.2.2. for REESS designed to be externally charged and shall be no less than 90 % of SOC according to paragraphs 6.2.1.2.1. and 6.2.1.2.2. for REESS designed to be charged only by an energy source on the vehicle. (Subject to confirmation by relevant TFs) The paragraphs 6.2.2.3.1.(b), 6.2.3.3.1.(b), 6.2.4.3.1.(b), 6.2.5.3.1.(b), 6.2.6.3.1.(b), 6.2.7.3.1.(b), amend to read 6.2.2.#.1. General test conditions: (b) at the beginning of the test, the SOC shall be adjusted in accordance with the paragraph 6.2.1.2.