Simulation of Ethylene glycol Extraction with 1

advertisement

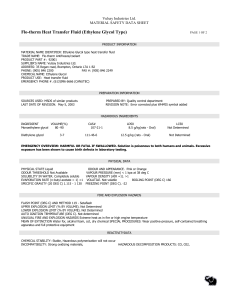

Third International Symposium on Environmental and Water Resources Engineering 2-3 June 2015, Tehran , Iran Simulation of Ethylene glycol Extraction with 1-Heptanol as Solvent to prevent infiltration to groundwater H. Ghazvini Nazmabad*, H. Ghanadzadeh, A. Ghanadzadeh Department of Chemical engeeniring, University of Guilan, Rasht, Iran Hadiseh.ghazvini@yahoo.com 1. INTRODUCTION ethylene glycol (EG) is an organic compound primarily used as a raw material in the manufacture of polyester, fibers and fabric industry, and polyethylene terephthalate resins (PET) used in bottling. A small percent is also used in industrial applications like antifreeze formulations and other industrial products [1,2]. Ethylene glycol is a high production volume chemical, it breaks down in air in about ten days, and in water or soil in a few weeks. It enters the environment through the dispersal of ethylene glycol containing products, especially at airports where it is used in deicing agents for runways and airplanes. ethylene glycol is a teratogen. Based on rather extensive database, it induces in rats and mice by all routes of exposure [3,4]. In this study, extraction of ethylene glycol from aqueous solution was studied usig 1-Heptanol as a solvents at T = 25 ºC, and atmospheric pressure. 2. SIMULATION 2.1 Problem definition The feed is a mixture made up of 80 mole% of water and 2 mole% of EG, with a flow rate of 80 kg/hr. The flow diagram for EG extraction process is shown in Fig 1. The extraction column was optimized at 6 plates and data for distillation column is shown in Table 1. 1 Third International Symposium on Environmental and Water Resources Engineering 2-3 June 2015, Tehran , Iran Figure 1. Flow diagram of Ethylene glycol separation process Table 1. Initial input data for distillation column Number of stages Feed stage Reflux ratio Distillat ratio 13 5 1.5 0.9 2.2 Property packeg Computer simulation using commercial process simulators is a useful tool to predict qualitatively the influence of the operating variables on the column performance, provided that the interaction binary parameters for the studied mixture are available in their own databank. The accuracy of the simulated results is strongly dependent on the quality of the binary parameters from the liquid phase activity coefficient models for this simulation, UNIQUAC activity model was chosen because it was the best model to study the phase behaviour of Liquid-Liquid Equilibrium (LLE), Vapour–Liquid Equilibrium (VLE) [5].It should be noted that, in this table temperature unit is oC. Mass fraction of components in streams are presented in Table 2. Table 2. Mole fraction of components in streams Stream ID Water Ethylene glycol Recycle Water 0.915 Trace 0.941 C2 H6O2 0.069 1.000 0.051 C8 H18O3 0.016 130 ppm 0.007 2 Third International Symposium on Environmental and Water Resources Engineering 2-3 June 2015, Tehran , Iran 2.3 Extractive distillation Extractive distillation has the inherent disadvantage of introducing a third component into the system (the solvent) that will appear in the product streams, which necessarily have to be recovered. So, the extractive system must show significant economic advantages over the pressure-swing system to make it the process of choice. 3. SELECTIVITY FACTOR Separation factor is defined as the ratio of distribution coefficients of phosphoric acid (D2) to water (D1) (Eq. (1)): S D2 w23 w21 D1 w13 w11 (1) w11, and w21 are the mass fractions of water and EG in the aqueous phase, respectively and listed in Table 3. w13, and w23 are the mass fractions of water and PA in the organic phase, respectively and listed in Table 3. The separation factors for the organic solvent are greater than one (S>>1) for the system, which means that the simulation of WEG extraction using 1Heptanol is possible. That the distribution coefficients and the separation factors for the system at T=25oC are listed in Table 3. Table 3. Mass fractions of organic phase in column extraction and distribution coefficients of water (D1) and EG (D2) and separation factors (S). w13 w23 D1 D2 S 0.0001 0.9999 0.0001 5.2351 52351.0000 4. CONCLUSIONS The separation of substances by distillation or other methods that have high energy consumption and are harmful to the environment, are not environmentally and economically useful. Solvent extraction method has been proposed to be a promising method with its high distribution coefficient, simplicity, and low energy demand. The simulation of processes with a commercial software program (Aspen plus) used appropriately is a very powerful tool to analyze the separation EG of the aqueous mixtures with 1-Heptanol. The thermodynamic equations used here are UNIQUAC equations. The selectivity factors for this solvent were calculated and the high value of this factor (s>>1), is reason for be suitable of the solvent for 3 Third International Symposium on Environmental and Water Resources Engineering 2-3 June 2015, Tehran , Iran extraction of EG in aqueous solution. 5. REFERENCES [1] H. C.Fuller, Ethylene Glycols, Products & Technology American chemistry council , Ethylene Glycol _ Its properties and uses, Indtitute of industrial research,Washington.D.C. [2] Y. Kakimoto, Y. Oka, Method for production of ethylene glycol, US 6417411 B2, (2001). [3] Statement of the Science Report for Ethylene Glycol, (2013-2014). [4] J. M. Hollis, F. J. Lovas, P. R. Jewell, L. H. Coudert, Interstellar Antifreeze: Ethylene Glycol, The Astrophysical, (2002). [5] Garcia-Flores BE, Galicia-Aguilar G, Rincon RE, Trejo A. Fluid Phase Equilib. 185 (2001) 275-293. 4