Koval JVST SM

advertisement

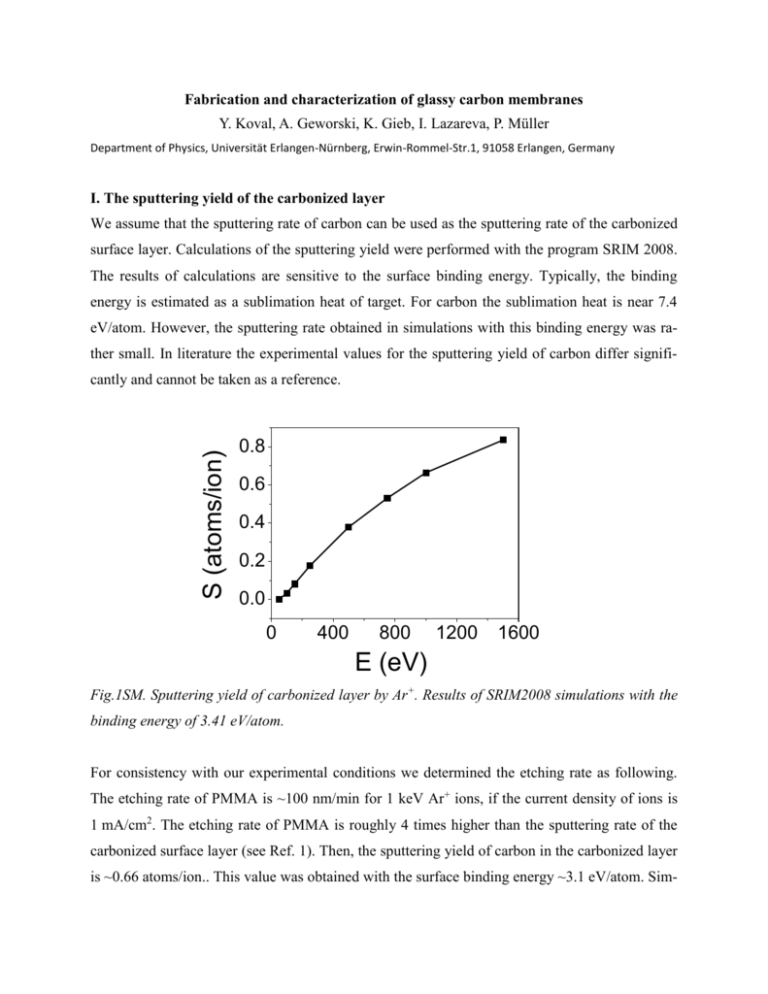

Fabrication and characterization of glassy carbon membranes Y. Koval, A. Geworski, K. Gieb, I. Lazareva, P. Müller Department of Physics, Universität Erlangen-Nürnberg, Erwin-Rommel-Str.1, 91058 Erlangen, Germany I. The sputtering yield of the carbonized layer We assume that the sputtering rate of carbon can be used as the sputtering rate of the carbonized surface layer. Calculations of the sputtering yield were performed with the program SRIM 2008. The results of calculations are sensitive to the surface binding energy. Typically, the binding energy is estimated as a sublimation heat of target. For carbon the sublimation heat is near 7.4 eV/atom. However, the sputtering rate obtained in simulations with this binding energy was rather small. In literature the experimental values for the sputtering yield of carbon differ signifi- S (atoms/ion) cantly and cannot be taken as a reference. 0.8 0.6 0.4 0.2 0.0 0 400 800 1200 1600 E (eV) Fig.1SM. Sputtering yield of carbonized layer by Ar+. Results of SRIM2008 simulations with the binding energy of 3.41 eV/atom. For consistency with our experimental conditions we determined the etching rate as following. The etching rate of PMMA is ~100 nm/min for 1 keV Ar+ ions, if the current density of ions is 1 mA/cm2. The etching rate of PMMA is roughly 4 times higher than the sputtering rate of the carbonized surface layer (see Ref. 1). Then, the sputtering yield of carbon in the carbonized layer is ~0.66 atoms/ion.. This value was obtained with the surface binding energy ~3.1 eV/atom. Sim- ilar binding energy were found in Ref. 2. With this binding energy the sputtering yield of carbon was calculated for different energies of Ar+ ions. The results of calculated carbon sputtering yields are shown in Fig. 1SM. The sputtering yield decreases monotonically with decreasing the energy of Ar+ ions. At 50 eV the sputtering becomes negligible. II. Thickness of the carbonized layer. Distributions of the density of the deposited energy in the steady state regime of etching were calculated for different Ar+ ions energies. The sputtering yields calculated with SRIM2008 (see Fig.1SM) were used to specify the speed of the etching. The results are summarized in Fig. 6. The distribution becomes narrower, and the maximum of the distribution decreases for lowerenergy ions. However, for the energies lower than 500 eV the maximum starts to increase. This is the consequence of a fast drop of the sputtering rate with decrease of the energy of ions. 200 3 (keV/nm ) 160 1500 eV 1000 eV 120 750 eV 500 eV 250 eV 80 40 0 0 2 4 6 depth (nm) Fig. 2SM. A steady state distribution of the density of the energy deposited in carbon by Ar+ ions. The thickness of the carbonized layer can be found as the depth, which corresponds to the threshold density of the deposited energy for carbonization. At higher the material can be considered as completely carbonized, and further increase of the deposited energy does not change the state of the surface layer. At lower the transformation is not complete, and the surface layer consists partially of cross-linked fragments. The threshold value used in Ref. 1 was 38 keV/nm3. In Fig. 3SM the dependence of the graphitized layer thickness vs. the energy of ions for this threshold value is shown. In Ref 3 the thickness of the graphitized layer was calculated by MD and determined experimentally for Ar+ ions with the energies 100-150 eV. The thicknesses of the graphitized layer found by Bruce et al. (Ref. 4) are slightly larger than ours. Alhough the discrepancy is small, in order to achieve better consistence we found the thicknesses for equal to 30 keV/nm3 and 20 keV/nm3 (see Fig. 3SM). In the following we use a value of 20 keV/nm3 which is in a good agreement with Bruce et. al. The thickness of the carbonized layer grows slower compared to the ion energy . E.g., an increase of the energy from 250 eV to 1500 eV leads to an increase of the thickness L by only a factor of ~2.5. 5 3 38 keV/nm 3 30 keV/nm 3 20 keV/nm L (nm) 4 3 2 1 0 400 800 1200 1600 E (eV) Fig. 3SM. Thickness of the graphitized layer vs. the energy of Ar+ ion. The thicknesses were found for three threshold densities of the deposited energy: 38 keV/nm3 (circles); 30 keV/nm3 (triangles), and 20 keV/nm3 (squares). III. Calculation of the temperature distribution. If the heat transfer by thermal conductance is the dominating mechanism for cooling, the maximum temperature increase T in the middle of a rectangular shaped membrane, can be estimated analytically as: 𝐸𝑖𝑜𝑛 × 𝑗 𝐿2 ∆𝑇 = ∙ 2𝜅 × 𝑡 4 where Eion is the ion energy in eV, j is the ion current density in A/cm2, - is the heat conductivity of the membrane in Wm-1K-1, t and L are the thickness and the length of the membrane in m, respectively. T does not depend on the width of the membrane. For complex membrane shapes and in case of high temperatures, where thermal emission is no longer negligible, the equation 4 ) 𝜕 2 𝑇 𝜕 2 𝑇 𝑝 2𝜎(𝑇 4 − 𝑇𝑒𝑛𝑣 + + − =0 𝜕𝑥 2 𝜕𝑦 2 𝑡 𝑘·𝑡 has been solved numerically by means of finite differencing, in order to calculate the temperature distribution. In this equation 𝑝 is the power density, 𝑡 the thickness of the membrane, and 𝑘 the thermal conductivity. Two boundary conditions were used: - Open: No heat transfer (beside thermal irradiation) - Closed: The border is in contact with the environment and pinned to a constant temperature. Variations in the thickness and the weak temperature dependence of 𝑘 were neglected. The equation is solved by a computer program in two steps. First, the radiation part is neglected and the linear part is computed with a linear decomposition approach5. After this, a relaxation approach6 is used to calculate the temperature distribution for the full equation. The program (windows executable) along with an usage description can be downloaded from our web page www.pi3.uni-erlangen.de/mueller/mebrane-tempdistr.zip. References 1 Y. Koval, J. Vac. Sci. Technol. B 22, 843 (2004). 2 W Jacob, C Hopf and M Schlüter, Phys. Scr. T 124 32–36 (2006). 3 J. J. Végh, D. Nest, D. B. Graves, R. Bruce, S. Engelmann, T. Kwon, R. J. Phaneuf, G. S. Oehr- lein, B. K. Long, C. G. Willson, J. Appl. Phys. 104, 034308 (2008). 4 R. L. Bruce, S. Engelmann, T. Lin, T. Kwon, R. J. Phaneuf, G. S. Oehrlein, B. K. Long, C. G. Willson, J. J. Végh, D. Nest, D. B. Graves, A. Alizadeh, J. Vac. Sci. Technol. B 27, 1142 (2009). 5 W.H. Press, A. Teukolsky, W.T. Vetterling, B.P. Flannery, Cambridge University Press, (2007). 6 J. M., Ortega; W. C., Rheinboldt, Philadelphia, PA: Society for Industrial and Applied Mathe- matics (SIAM) 30, (2000).