SUPPORT INFO-CEsteves-Self-replenishing of

advertisement

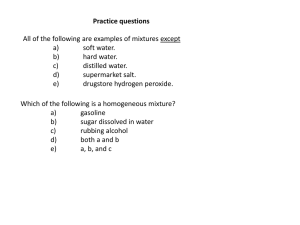

Self-replenishing ability of cross-linked low surface energy polymer films investigated by a complementary experimentalsimulation approach A.C.C. Esteves1*; K. Lyakhova1; J.M. van Riel1; L.G.J. van der Ven1,2; R.A.T.M. van Benthem1,3; G. de With1* SUPPORTING INFORMATION SIMULATIONS Parameterization: Parameterization of the coarse grained DPD beads is described in detail in ref.[1] Beads of the same type repulsion parameter was taken a ij 25 (in units k B T ).[2] The excess repulsion between beads was calculated using Flory-Huggins interaction parameters . The relations between a ij and a ii is aij aii 3.49 [2]. The Flory-Huggins parameters ij were calculated via solubility parameters ij V0 ( i j ) 2 / RT , where V 0 is the molar volume of the solvent and i and j are self-solubility parameters. Solubility parameters i were obtained from group molar contributions[3]. For calculation of solubility parameters Molecular Modelling Pro package was used[4]. The interaction between the artificial ‘void’ bead (V bead) and other beads was taken aVi 60 in order to insure the separation between polymer film and ‘air’ phase. The interaction between CL-H beads and C-beads was taken a CL H ,C 10 in order to increase probability of cross-linking. 1 SM-TABLES Table SM-1 Tri-functional polyester precursors (TMP-PCLx) and respective characterization. TMP-PCLx x n Mn Mn (3n) (DP) H1NMR g/mol GPC PDI GPC Mw/Mn Mn MALDI g/mol DSC Tg (°C) DSC Tm (°C) g/mol TMP-PCL18 18 6 1590 2468 1.18 1650 -74 21 TMP-PCL24 24 8 2230 2480 1.19 2455 -72 35 TMP-PCL36 36 12 2892 4533 1.14 2683 -72 36 TMP-PCL48 48 16 3890 6428 1.11 3826 -71 41 Table SM-2: Polymeric dangling chains (F17C8-PCLy) and respective characterization. y F17C8-PCLy (DP) Ther. Mn Mn Mn H1NMR g/mol GPC PDI GPC Mw/Mn Mn MALDI g/mol DSC Tg (°C) DSC Tm (°C) g/mol F17C8-PCL8 8 1400 1648 2818 1.13 1415 -65 47 F17C8-PCL12 12 1800 1924 3191 1.17 2101 -66 50 F17C8-PCL16 16 2300 2042 3804 1.06 2329 -65 50 F17C8-PCL22 22 2800 2192 3781 1.12 2443 -64 50 Self-replenishing efficiency (SRE) calculation based on F/C and CA measurements: errors consideration and estimation. The unexpected increase of the F/C atomic ratios after damage may be explained by a possible contribution from cross-contamination during the cryo-microtoming or XPS measurement. In order to reduce this effect, the data points (and related error bars for sample standard deviation) 2 shown in Figure 4 a, are an average of the measurements collected at four different spots on three film replicas. For the CA measurements, several other aspects have also to be taken in consideration. The caprolactone based systems, as used in this study, have been reported to have large CA hysteresis due to surface-rearrangements[5]. Once the surfaces are damaged (at cryogenicconditions) they are exposed to some water upon returning to room temperature (from condensation) which may induce changes on the surface composition or permanent damages on the network, e.g. by hydrolyses of the ester bonds. In fact the receding CA recovery was considerably lower than for the advancing (about 40 to 60 %, not shown). Moreover, although the cryo-microtoming procedure should produce surfaces with a limited roughness and no surface defects[6], the introduction of roughness, possible indentations of the knife and crosscontamination cannot be discarded as an additional source of errors. The self-replenishing efficiency based on the F/C and CA experimental data calculated using Equation 2 and 3, respectively. The error associated with these calculations was estimated using Equation 4 and 5, respectively. Estimated errors for SRE: ∆SRE 2 ( SRE ) = ( ∆SRE 2 ( SRE ) = ( ∆(FC after cut) 2 FC after cut ∆(CA after cut) 2 CA after cut ∆(FC original) 2 ) +( FC original ) ∆(CA original) 2 ) +( CA original ) Eq. 4 Eq. 5 References [ 1] Travis K.P. BM, Good K., Owens S.L. J ChemPhys 2007;127. [ 2] Groot RD and Warren PB. J Chem Phys 1997;107:4423-4435. 3 [ 3] van Krevelen DW. "Properties of Polymers", 2nd ed. Amsterdam: 2nd edition , Elsevier, 1990. [ 4] Molecular Modeling Pro, Norgwyn Montgomery Software Inc., 1992. [ 5] Esteves ACC, Lyakhova, K, van der Ven, L. G. J.; van Benthem, R. A. T. M.; de With, G. Macromolecules 2013;46:1993-2002. [ 6] Dikic T, Ming W, van Benthem RATM, Esteves ACC, and de With G. Adv Mater 2012;24:3701-3704. SI-FIGURE original after (60 µm) damage 0.32 0.28 0.24 0.20 0.16 F/C atomic ratio 0.12 0.08 a) 0.04 0.32 original after damage 0.28 0.24 0.20 0.16 0.12 0.08 0.04 b) 16 20 24 28 32 36 40 44 48 TMP-PCLx Figure SM-1. Experimental (a) and simulation (b): Fluorine/Carbon (F/C) atomic ratio as a function of the length (DP) of the polymer network precursor (TMP-PCLx, x = 3·n CL units). F17C8PCL16 dangling chains and 2 wt % of fluorine were used in the formulation. Errors bars represent the sample standard deviation. 4