Employ a Contract Packager for Seasonal Flex Demands

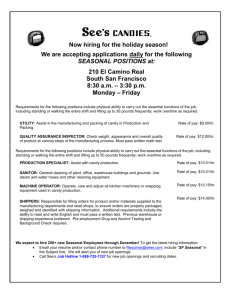

advertisement

Employ a Contract Packager for Seasonal Flex Demands “OEM manufacturers and accessory parts suppliers can drastically reduce internal labor and equipment cost during high-demand seasonal periods by partnering with a full service contract packaging firm such as Fapco,” states President and Founder of Fapco, Larry Gardiner. Many OEMs and their major parts suppliers handle parts fulfillment just fine during the steady parts flow periods but fail to meet the demands of seasonal flex periods. Fapco is ready to assist in seasonal, high-volume parts and accessory contract packaging needs for manufacturers’ seasonal products. From snowmobile, wood stove, snowplow and snow blower, to boating, RV and outdoor recreational products in the summer months, the fall and spring are high volume packaging and fulfillment months for many of these OEMs. As the legions of consumers prep the snowmobile for winter runs or tune up the mower for the season, parts requirements increase. In a tough economy, consumers may also be holding onto older equipment longer, thus increasing the need for maintenance parts. Scott Sloniker, Operations Manager for Fapco, explains why companies need the services of a contract packager during these peak periods. “There are a lot of OEMs that are very seasonal. They don’t want to add to their own workforce in-house, or invest in higher volume packaging equipment, so they come to us for a wide variety of contract packaging needs to handle these peak periods. Agricultural equipment is a perfect example of seasonal demand for parts. Spring and fall are busy periods as farmers repair and maintain equipment. We often work with our ag OEMs to create maintenance kits that include parts that are commonly replaced each season,” he says. Sloniker states that planning ahead is key. “Typically the lead time for this type of fulfillment starts three to five months ahead of the peak season. For example, if you are talking about supporting spring planting for the ag business, January and February are the months to prepare for the March, April and May increase in parts demand. In the boat business on the other hand, companies prepare for winter maintenance in the late summer and early fall.” When bringing on a new customer for flex packaging, the Fapco team provides close support as the program ramps up. “We provide software and systems integration to the exacting demands of each customer,” elaborates Sloniker. “Do they want us on their system? What kind of firewall do they want? We are capable of doing whatever the customer needs in these areas and have worked with some of the most sophisticated logistics software on the planet with major automotive makers.” “Once the system is up and running, we have to stay on top of the program to get it running true. We typically meet with the customer once a week and have numerous conference calls. We dedicate specific plant managers and customer service teams to each customer to make sure the process is under continuous improvement. It’s important to us that we exceed each new customers’ expectations,” Sloniker concludes. Begin the Process of Partnering with a Contract Packager for Seasonal Flex Demand 1. Make a thorough review of your supplier base—Simply put, is your supply base ready to help you meet your flex parts fulfillment needs? This involves gauging how much inventory is out there, how much inventory you want in the network coming through the fulfillment house and how much product is in the pipeline to replenish the contract packager to support the campaign. 2. Assess your current parts packaging/distribution/warehouse system. Do you currently have a parts distribution warehouse system? If not, where can you build in efficiencies using the full range of services from your contract packaging and fulfillment supplier? You may want to consolidate all your suppliers to ship, warehouse and fulfill through your full service contract packager during these peak periods. 3. Are there procurement opportunities with your contract packaging partner that can expedite the supply chain? Well-established, full service contract packagers such as Fapco can actually procure the parts directly from your supply base during peak demand periods. This can expedite the supply chain dramatically. In this scenario, parts are ordered and purchased by the contract packager. Once received parts are packaged and shipped or warehoused based on historical peak demands. 4. Work with the full-service contract packager to streamline and customize your packaging needs. How does this flex demand packaging usually ship and is there a better way? Is it in bulk boxes, point of purchase or point of sale materials—from clamshells to blister packs for rack hanging? The team at Fapco will work closely with your flex demand campaign managers to make sure the packaging is right to save you time and lower your costs. Whatever your packaging and display guidelines and specifications, Fapco works to make them better and less costly. 5. How is the product coming in and what is the plan to fulfill? Is the product coming in raw in an overseas container? Will Fapco be purchasing some components directly? Once this is determined what will the flex program actually be? Many manufacturers ship specific numbers of seasonal parts to distribution centers or dealerships based on previous years’ demand. Others support the launch of new products, equipment or vehicles with estimated seasonal bundles. Fapco has the experience with a wide variety of OEMs to help your company work through this seasonal program in the most efficient manner. Sloniker sums up the OEM contract packaging partnership process for new seasonal demand customers. “As we ramp up a new flex demand customer, we ask, ‘Can your parts suppliers get the product to us? How do you want them packaged? Where do you want them shipped? How quickly do you want the parts distributed?’ That’s basically what we find out very quickly on the front end and then proceed with the seasonal flex program,” he concludes. From working with your marketing department to bundle and kit parts and design the right packaging for seasonal point-of-purchase displays, to taking the hassles away from your purchasing department with direct supplier procurement, followed by parts packaging, warehousing and strategic fulfillment, Fapco is your full-service, seasonal flex-demand contract packaging partner.