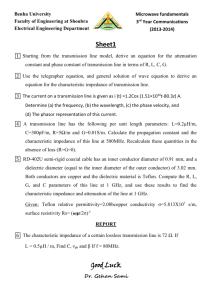

Impedance Tube - part 2

advertisement

CUA

THE CATHOLIC UNIVERSITY OF AMERICA

School of Engineering

Department of Mechanical Engineering

620 Michigan Ave.

Washington DC 20064

Acoustic Metrology

Chapter 4

Impedance Tube - part 2.

Characteristic impedance, wavenumber and porous material design

Diego Turo, Joseph Vignola and Aldo Glean

June 28, 2012

http://mason.gmu.edu/~dturo/collaborations/CUA_Lecturer_ME_661.html

Impedance tube – part 2

DETERMINATION OF THE ACOUSTIC CHARACTERISTIC IMPEDANCE AND WAVENUMBER ................................... 3

TWO-CAVITY METHOD (UTSUNO ET. AL., 1989) .............................................................................................................................................. 3

TWO-THICKNESS METHOD .................................................................................................................................................................................... 4

SURFACE IMPEDANCE OF A MULTILAYERED MEDIUM ....................................................................................................................................... 6

COMPLEX WAVENUMBER: ATTENUATION COEFFICIENT AND PHASE SPEED ................................................................................................. 7

POROSITY ............................................................................................................................................................................................. 8

HOW TO MEASURE POROSITY (ZWIKKER AND KOSTEN, 1949; CHAMPOUX ET AL., 1991). ..................................................................... 8

BERANEK METHOD ................................................................................................................................................................................................. 9

CHAMPOUX ET AL. METHOD.................................................................................................................................................................................10

FLOW RESISTIVITY .......................................................................................................................................................................... 11

FLOW RESISTIVITY OF A MATERIAL WITH STRAIGHT CYLINDRICAL PORES .................................................................................................11

HOW TO MEASURE FLOW RESISTIVITY ..............................................................................................................................................................12

SIMPLE MODELS OF SOUND PROPAGATION IN POROUS MEDIA ..................................................................................... 13

DELANY-BAZLEY MODEL (DELANY AND BAZLEY, 1970) .............................................................................................................................13

ASSIGNMENTS ........................................................................................................................................................................................................14

REFERENCES ...................................................................................................................................................................................... 17

MATLAB CODES ................................................................................................................................................................................ 18

CHARACTERISTIC IMPEDANCE AND WAVENUMBER MEASUREMENT: TWO THICKNESS METHOD ............................................................18

CHARACTERISTIC IMPEDANCE AND WAVENUMBER MEASUREMENT: TWO CAVITY METHOD ...................................................................19

Determination of the acoustic characteristic impedance and

wavenumber

Two-cavity method (Utsuno et. al., 1989)

In the figure below, a layer of porous material is placed in an impedance tube and an air gap of depth L is left

behind it.

Figure 1. Impedance tube setup for two-cavity method measurements.

The acoustic impedance at the reference surface, Z 0 , can be related to the characteristic impedance Z c of the

porous material, the propagation constant (wavenumber) k inside the porous material, the acoustic impedance

behind the porous material, Z1 , and the material thickness d , as follows

- jZ1 cot ( kd ) + Zc

Z coth ( jkd ) + Zc

Z0 = Zc

= Zc 1

Z1 - jZc cot ( kd )

Z1 + Zc coth ( jkd )

Z1 coth ( jkd ) + Zc

Z cosh ( jkd ) + Zc sinh ( jkd )

= Zc 1

Z1 + Zc coth ( jkd )

Z1 sinh ( jkd ) + Zc cosh ( jkd )

Z 0 éë Z1 sinh ( jkd ) + Z c cosh ( jkd )ùû = Zc éë Z1 cosh ( jkd ) + Z c sinh ( jkd )ùû

Z0 = Zc

e jkd - e- jkd

2

- jkd

e + e jkd

cosh ( jkd ) =

2

Z 0 Z1 ( e jkd - e- jkd ) + Z 0 Z c ( e- jkd + e jkd ) = Z c Z1 ( e- jkd + e jkd ) + Z c2 ( e jkd - e- jkd )

sinh ( jkd ) =

(Z Z + Z Z

0

1

0

c

- Zc Z1 - Z 2 ) e jkd = ( Z 0 Z1 - Z 0 Z c + Z c Z1 - Z c2 ) e- jkd

( Z 0 - Zc ) ( Z1 + Zc ) e jkd = ( Z 0 - Zc ) ( Z1 + Zc ) e- jkd

which yields to

Z0 + Zc Z1 - Zc

= e 2 jkd

Z0 - Zc Z1 + Zc

since the right-hand side of the above equation does not change with the depth of the air gap L , one can

perform a second surface impedance measurement with a different air gap L ' and write

Z 0 + Zc Z1 - Zc Z0 '+ Zc Z1 '- Zc

=

Z0 - Zc Z1 + Zc Z0 '- Zc Z1 '+ Zc

where Z 0 ' and Z1 ' are the new surface impedances associated to the air gap L ' .

Solving the previous equations for Z c and k gives

1

é Z Z ' ( Z - Z ') - Z Z ' ( Z - Z ') ù2

1 1

0

0

Z c = ±ê 0 0 1 1

ú

êë

úû

( Z1 - Z1 ') - ( Z0 - Z0 ')

Z Zc Z1 Zc

1

ln 0

2 jd Z0 Zc Z1 Zc

where Z1 and Z1 ' can be estimated with

k

Z1 = - jZair cot ( kair L)

Z1 ' = - jZair cot ( kair L')

and the sign of the Z c is chosen so that the real part of Z c is positive.

Two-thickness method

A further method to evaluate the characteristic impedance and the wave number of a porous material is to use

two samples of the same material having one the thickness double of the other.

In the figure below, a layer of porous material is placed in an impedance tube and a rigid back is left behind it.

Figure 2. Impedance tube setup for two-thickness method.

Measurement are performed on two samples. The first sample has a thickness equal to d and its surface

impedance is equal to

Z1 jZc cot kd

The second sample has thickness equal to 2d and its surface impedance is equal to

Z2 jZc cot 2kd

The characteristic impedance and the propagation constant can then be evaluated as follows

Zc Z1 2Z 2 Z1

1

2

1ù

é

ê æ 2Z 2 - Z1 ö 2 ú

÷ ú

ê1+ ç Z

1

è

ø ú

1

k=

ln ê

1

ú

2 jd ê æ

2

ö

ê1- ç 2Z 2 - Z1 ÷ ú

ê è Z

ø úû

ë

1

where expression of Z c is derived from the trigonometric identity

()

()

( )

(

)

1+ coth 2 x = 2coth x coth 2x

from which

Z2

Z Z

1+ 12 = 2 1 2

Zc Zc

Zc

Z c2 + Z 12 = 2Z1Z 2

Z c2 = 2Z1Z 2 - Z 12 = Z1 2Z 2 - Z1

(

)

1

2

Z c = éëZ1 2Z 2 - Z1 ùû

and expression of k is derived from the trigonometric identity

coth x +1 2 x

=e

coth x -1

()

()

in fact

Z1

Z

+1 1+ c

coth jkd +1 Z

Z1

= c

=

Z

coth jkd -1 Z1

-1 1- c

Zc

Z1

( )

( )

1

æ 2Z - Z ö 2

1

÷÷ so

from the expression of Z c we have Zc = Z1 çç 2

è Z1 ø

1

æ 2Z - Z ö 2

1

1+ ç 2

÷

Z

è

ø

1

Zc

Z1

=

= e 2 jkd

1

Zc

æ 2Z - Z ö 2

11

÷

Z1 1- ç 2

è Z1 ø

1+

from which

1ù

é

ê æ 2Z 2 - Z1 ö 2 ú

÷ ú

ê1+ ç Z

1

è

ø ú

1

k=

ln ê

1

ú

2 jd ê æ

2

ê1- ç 2Z 2 - Z1 ö÷ ú

ê è Z

ø úû

ë

1

In Figure 3 and Figure 4 characteristic impedance and wavenumber measured from a rockwool sample have

been plotted.

4

air

Re[Z ()/Z ]

3

c

2

1

0

-1

200

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

1

c

air

Im[Z ()/Z ]

0

-1

-2

-3

-4

200

Figure 3. Complex characteristic impedance ratio of rockwool measured with two-thickness method. Top curve is the real part and bottom curve is

the imaginary part.

60

-1

Re[k()] (m )

50

40

30

20

10

0

200

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

0

Im[k()] (m-1)

-5

-10

-15

-20

-25

-30

200

Figure 4. Complex wavenumber of rockwool measured with two-thickness method. Top curve is the real part and bottom curve is the imaginary

part.

Surface impedance of a multilayered medium

The impedance of a multilayered medium can be easily evaluated applying the translation theorem layer by

layer. Let’s solve the case when the porous medium is made out of two layers only as shown in Figure 5.

Starting from a known impedance at x = x2 , Z ( x1 ) is evaluated with

( )

( )

( )

Z x1 = - jZc2 w cot éëk2 w d2 ùû

or directly measured in an impedance tube experiment. Then, Z ( x1 ) can be used as know impedance for the

next layer so that Z ( x1 ) can be evaluated as follows

Z ( x0 ) = Zc1 (w )

- jZ ( x2 ) cot éëk1 (w ) d1 ùû + Zc1 (w )

Z ( x2 ) - jZc1 (w ) cot éëk1 (w ) d1 ùû

which can measured in an impedance tube too. However, what is really interesting and important about these

equations is that there is no need to perform any experiment for predicting acoustic behavior of a multilayered

medium with different layer thickness once characteristic impedance and wavenumbers of each layer are know.

The design of a new acoustic absorbing media can take place.

Figure 5. Surface impedance of a multilayered medium.

Complex wavenumber: attenuation coefficient and phase speed

When a plane sound wave is travelling in a fluid or in a porous media, viscous and thermal effects make the

wave amplitude changing (in a porous media phase changes too) with the travelled distance. For plane waves

travelling in air, these effects are very small and often negligible. However, for plane waves travelling in porous

media, these effects are extremely strong and knowledge of this parameter is very important when designing

highly acoustically absorbing walls, i.e. anechoic chamber walls, bunker walls, airplane fuselage etc.

Acoustic attenuation x (w ) is an exponential decay of the sound amplitude with the distance and it is described

by the following equation:

P ( x2 ) = P ( x1 ) e

- x (w ) x2 -x1

where P ( x2 ) and P ( x1 ) are acoustic pressures at locations x2 and x1 respectively.

Plane wave travelling in a porous media can be expressed by

jéwt-k (w ) xùû

P ( x,t ) = A (w ) e ë

= A (w ) e jwt e

- jk (w ) x

= A (w ) e jwt e

- jéëRe{k(w )}+ j Im{k(w )}ùûx

where k (w ) = Re {k (w )} + j Im {k (w )} = e (w ) + jx (w ) so

jéwt-e (w ) xù x w x

û ( )

P ( x, t ) = A (w ) e jwt e ( ) e ( ) = A (w ) e ë

e

It is now clear that attenuation coefficient is the imaginary part of the complex wavenumber. Remember that

wavenumber in air is a real quantity only because viscous and thermal effects are considered negligible.

Real part of the wavenumber is accounting for the change of the speed of sound in the medium. In fact

w

e (w ) = Re {k (w )} =

c (w )

- je w x x w x

( )

where c w is the phase speed in the medium and is frequency dependent.

In Figure 6 phase speed and attenuation coefficient measured from a rockwool sample have been plotted

250

c() (m/s)

200

150

100

50

0

200

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

Attenuation coefficient (m-1)

0

-5

-10

-15

-20

-25

-30

200

Figure 6. Phase speed and attenuation coefficient of rockwool measured with two-thickness method.

Porosity

Materials such as fiber-glass and plastic foam with open bubbles consist of an elastic frame which is surrounded

by air. Packing of sand, gravel and metallic foam are rigid frames surrounded by air. The porosity f is the ratio

of the air volume Vair to the total volume of porous material V . It is therefore defined as

f=

Vair

V

If Vframe is the volume occupied by the frame in V , then the quantities Vair , Vframe and V are related by

Vair +Vframe = V

Only the volume of air which is not locked within the frame must be considered in Vair and thus in the

calculation of the porosity. The latter is also known as the open porosity or the connected porosity. For instance,

a closed bubble in a plastic foam or in a metal foam is considered locked within the frame, and its volume

therefore belongs to Vframe . For most of the fibrous materials, plastic foams and metallic foams, the porosity lies

very close to 1.

How to measure porosity (Zwikker and Kosten, 1949; Champoux et al., 1991).

The most simplistic way to measure porosity of “impermeable” rigid frame porous media is to fill its pores with

a fluid (like water) of known density (here the word impermeable is used to describe a pores-network which

does not change geometry when wet). Then empty the porous frame and measure the mass of the fluid. Dividing

this mass by its density leads to the open-pores volume if no fluid is left within the frame. Porosity is given by

the ratio of the open-pores volume and the porous media volume.

This method is obviously not applicable to all porous media since only a few of them are “impermeable”, i.e.

packing of rigid spheres, rocks or gravel and metallic foams. Whereas most of the widely used sound absorbing

materials are “permeable”, i.e. glass wool, carpets and plastic foams.

Another very simple method for measuring porosity is based on the knowledge of the frame density r frame . In

fact if r frame is known, one can write

V

M

/r

Vair V -Vframe

=

=1- frame =1- frame frame

V

V

V

V

where the frame volume Vframe can be easily measured. It is given by the weight of the sample divided by its

density. In order to reduce the error due to the material voids at the boundary, the use of bulk sample is

suggested.

More elaborated methods for measuring porosity of porous material were proposed by Leo Beranek (1942),

Champoux et al. (1991), Umnova et al. (2005) and Panetton et al. (2012) (just to mention a few of them). Here

we explore in more details the methods proposed by Beranek and Champoux. However a more invasive but

very simple method for measuring porosity was suggested by Leonard (1948) where water was used to fill pores

of an impermeable rigid frame material and its volume used to estimate porosity of the medium (R. W. Leonard,

‘‘Simplified porosity measurements,’’ J. Acoust. Soc. Am., 20, 39–41, 1948).

f=

Beranek method

Beranek, “Acoustic Imedanceof Porous Materials”, J. Acoust. Soc. Am., 13, 1942

<< … The acoustical material of volume Vt is contained in a rigid chamber of volume V . The ambient

temperature is held constant. Initially, the stopcock is closed and one side of the manometer elevated until the

levels have changed from h to h1 and h2 , respectively. The pressure change Dp0 in centimeter of water equals

h2 - h1 and the reduction of volume of air DVa in the chamber equals ( h1 - h) S , where S is the area of cross

section of the connecting tube. The heights h and h1 are observed for accuracy by a cathetometer while

( h2 - h) may be read accurately enough on a graduated scale. The porosity is given by

p0 DVa

V

+1Vt Dp0

Vt

where p0 is atmospheric pressure and equals approximately 1035 cm of water. …>>

f=

The equation used by Beranek can be easily derived from the ideal gas law which, in case of isothermal

transformation, can be written as follows

pV = nRT = const

dpV + pdV = 0

dpV = -pdV

One can therefore write

Dp0 (V -Vframe ) = -p0 DVa

where Vframe is the volume occupied by the frame of the porous medium and if Dp0 > 0 then DVa < 0 . So if one

observes that Vframe = Vt (1- f ) then can write

p0 DVa

Dp0

which leads to the equation

p DV

V

f = 0 a +1Vt Dp0

Vt

V -Vt (1- f ) =

Champoux et al. method

Champoux et al., “Air-based system for the measurement of porosity”, J. Acoust. Soc. Am., 89, 1991

This method, like that of Beranek, is based on the ideal gas law.

<<… A sample of porous material, occupying a total volume Vt , is situated in a sealed chamber. Within the

connected pore spaces of the sample, a volume Va is air-filled; hence, completely encapsulated pockets of air

are not included. The volume fraction of air, in the material, is the porosity f ,

f=

Va

Vt

The total volume of air in the measurement chamber is V ' = V0 +Va , where V0 is the residual volume in the

sample chamber outside of the sample.

Initially, the chamber pressure is atmospheric pressure p0 . If the volume is caused to increase by an amount

DV , through movement of a piston, the pressure will change by an amount Dp' . For an isothermal expansion of

the assumed ideal gas in the chamber,

p0V ' = ( p0 + Dp') (V '+ DV )

Then, measurement of the pressure change Dp' , knowing p0 and DV , allows the total volume V ' of air to be

determined using

p0 + Dp'

DV

Dp'

The air content Va of the sample is then

Va = V '-V0

V'=-

and the porosity f can be calculated using its definition. …>>

Flow resistivity

Flow resistivity is defined by the ratio of the pressure differential across a sample of the material to the normal

flow velocity through the material. The flow resistivity σ is the specific (unit area) flow resistance per unit

thickness. Flow resistivity is one of the most important parameters governing the absorption of a porous

material.

A sketch of the set-up for the measurement of the flow resistivity σ is shown in the figure below.

The material is placed in a pipe, and a differential pressure induces a steady flow of air. The flow resistivity σ is

given by

(p - p )

s= 2 1

vh

in this equation, the quantities v and h are the mean flow of air per unit area of material and the thickness of

the material, respectively. In MKSA units, σ is expressed in N × m-4 × s .

Fibrous materials, however, are generally anisotropic (Attenborough 1971, Burke 1983, Nicolas and Berry

1984, Allard et al. 1987, Tarnow 2005). Fibers in the material generally lie in planes parallel to the surface of

the material. The flow resistivity in the normal direction is different from that in the planar directions. In the

former case, air flows perpendicularly to the surface of the panel while in the latter case it flows parallel to the

surface of the layer. The normal flow resistivity s N is usually much larger than the planar flow resistivity s P

and therefore it is important accounting for this phenomenon when designing sound absorbing walls or sailings.

Flow resistivity of a material with straight cylindrical pores

Suppose that the porous material has N cylindrical pores with radius r . According to the above equation, flow

resistivity is given by

(p - p )

s= 2 1

vf h

where v is mean velocity in a single pore. This equation can be derived as follows. Suppose that the sample

cross-section is A and that the single pore cross-section is An . Using Bernoulli equation one can write

vA = å vn An

n

where vn is particle velocity in the nth-pore. Because pores are assumed to be all equal then vn = v and

An = p r so that

åv A

= Nv ( p r ) . Therefore v = v

N (p r 2 )

= vf .

A

From the Newton equation for stationary flow ( w = 0 ) in a cylindrical pore, v is equal to

r 2 æ ¶p ö

v = ç- ÷

8h è ¶x ø

and therefore flow resistivity is given by

8h

s= 2

rf

2

n

n

n

2

How to measure flow resistivity

See MY Project at the University of Salford and

BS EN 29053 “Acoustics — Materials for acoustical applications. Determination of airflow resistance”, 1993

Tortuosity

Let’s consider a porous layer having pores of radius r lying in two directions symmetrical with respect to the

normal of the surface (as shown in the figure below).

The thickness of the layer is h , the length of the pores is L , and the differential pressure is p2 - p1 . The

velocities in the two pores, averaged over the cross-sections, are v1 and v2 . With N pores per unit area of

surface, the porosity f is given by

Np r2

f=

cosq

where q is the angle between the axes of the pores and the surface normal. The pressure gradient in the pores is

p2 - p1 p2 - p1

=

cosq

L

h

The flow resistivity s in the x direction is

p2 - p1

8h

s=

=

2

N v p r h N p r 2 cosq

(

)

where v is the modulus of the average velocities v1 and v2 . The flow resistivity s can be finally written as

8h

s= 2 2

f r cos q

which differ from the equation evaluated for straight cylindrical pore only by the factor of a¥ =1/ cos2 q . This

factor is called tortuosity because it accounts for the tortuous (non-straight) path that the sound wave has to

travel in order to go through the material. It is always equal or greater than one. Flow resistivity can therefore be

expressed by

8ha¥

s=

fr2

which is a more general expression for tubular pores with uniform radius equal to r .

How to measure tortuosity

Fellah Z.E.A. et al., “Measuring the porosity and the tortuosity of porous materials via reflected waves at

oblique incidence”, J. Acoust. Soc. Am., 113, 2424-33, 2003

Umnova O. et al., “Deduction of tortuosity and porosity from acoustic reflection and transmission

measurements on thick samples of rigid-porous materials”, Applied Acoustics, 66, 607–624, 2005

Simple models of sound propagation in porous media

Delany-Bazley model (Delany and Bazley, 1970)

The complex wave number k and the characteristic impedance Zc have been measured by Delany and Bazley

(1970) for a large range of frequencies in many fibrous materials with porosity close to 1. According to these

measurements, the quantities k and Zc depend mainly on the angular frequency w and on the flow resistivity s

of the material. A good fit of the measured values of k and Zc has been obtained with the following expressions:

Z c 0 c0 1 0.0571X 0.754 j 0.087 X 0.732

1 0.0978 X 0.7 j0.189 X 0.595

c0

where r 0 and c0 are the density of air and the speed of sound in air, and X is a dimensionless parameter equal

k

to X =

r0w

2ps

Delany and Bazley suggest that X has to be 0.01< X <1.0 in order for their laws to be valid. These boundaries

can be seen as frequency limits for a given material.

These single relations do not provide a perfect prediction of acoustic behavior of all the porous materials in the

frequency range previously defined. Nevertheless, the laws of Delany and Bazley are widely used and can

provide reasonable orders of magnitude for Z c and k . With fibrous materials the flow resistivity must be

measured in the direction of propagation for waves travelling in either the normal or the planar direction.

Several authors suggested slightly different empirical expressions of Z c and k for specific frequency ranges

and for different materials (Dunn and Davern 1986, Miki 1990).

In Figure 7 and Figure 8 Delany and Bazley model has been used as fitting function to predict the flow

resistivity of a rockwool sample

4

air

Re[Z ()/Z ]

3

c

2

1

0

-1

200

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

1

c

air

Im[Z ()/Z ]

0

-1

-2

-3

-4

200

Figure 7. Complex characteristic impedance ratio of rockwool measured with two-thickness method (blue line) and Delany-Bazley model (dotted

red line). Top curve is the real part and bottom curve is the imaginary part.

60

-1

Re[k()] (m )

50

40

30

20

10

0

200

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

400

600

800

1000

1200

Frequency (Hz)

1400

1600

1800

2000

0

Im[k()] (m-1)

-5

-10

-15

-20

-25

-30

200

Figure 8. Complex wavenumber of rockwool measured with two-thickness method (blue line) and Delany-Bazley model (dotted red line). Top curve

is the real part and bottom curve is the imaginary part.

Assignments

1. Estimate and measure the reflection coefficient of a multilayered medium.

2. Interchange the layers. Does the acoustic performance of the medium change? Why?

Answer: Yes it does. It can be demonstrated using the translation theorem. Let’s overlay two media

only: medium 1 with Z c1 k1 d1 and medium 2 with Z c2 k2 d2 , respectively. Let’s assume that medium

1 is backed by medium 2 which is backed by a rigid wall so that surface impedance of this absorber is

given by:

Z coth ( jk1d1 ) + Zc1

Z1 = Zc1 2

Z 2 + Zc1 coth ( jk1d1 )

however, because medium 2 is rigid backed, the above relationship can be written as follows

Zc2 coth ( jk2 d2 ) coth ( jk1d1 ) + Zc1 Zc1Zc2 coth ( jk2 d2 ) coth ( jk1d1 ) + Zc12

Z1 = Zc1

=

Zc2 coth ( jk2 d2 ) + Zc1 coth ( jk1d1 )

Zc2 coth ( jk2 d2 ) + Zc1 coth ( jk1d1 )

on the other hand, if we swap the layers, surface impedance of the absorber is now given by

2

Z Z coth ( jk2 d2 ) coth ( jk1d1 ) + Zc2

Z 2 = c1 c2

Zc2 coth ( jk2 d2 ) + Zc1 coth ( jk1d1 )

From these above equations it is clear that difference between the two configurations can be notice only

if characteristic impedances Z c1 and Z c2 of the media are different and it does not depend on

wavenumber of each layer. However, if the multilayered medium has more than two layers, the last

statement is not valid anymore.

This is shown in Figure 9 and Figure 10 where reflection and absorption coefficients of 2 different

multilayered media have been predicted using Delany-Bazley model.

3

In Figure 9 medium 1 has flow resistivity 1 20, 000 kg / s m and medium 2 has flow resistivity

2 15, 000 kg / s m3 and both have thickness equal to d1 d2 0.025 m . Because flow resistivities

of media 1 and 2 are not very different, their characteristic impedances are so too and differences in

performance between the 2 configurations (medium 2 at front medium 1 at back and vice versa) can be

barely detected.

Reflection Coefficient, R

1

Multi 2-1

Single 1

Multi 1-2

Single 2

0.8

0.6

0.4

0.2

0

500

1000

1500

2000

2500

3000

Frequency, Hz

3500

4000

4500

5000

Absorption Coefficient,

1

0.8

0.6

0.4

Multi 2-1

Single 1

Multi 1-2

Single 2

0.2

0

500

1000

1500

2000

2500

3000

Frequency, Hz

3500

4000

4500

5000

Figure 9. Comparison between reflection and absorption coefficients of 2 different multilayered media obtained using Delany-Bazley model. Dotted

blue lines are performances of a single layer of medium 1, dotted red lines are performances of a single layer of medium 2, solid blue lines are

performances of a multilayer medium composed by medium 2 at front and medium 1 at back, solid red lines are performances of a multilayer

3

3

medium composed by medium 1 at front and medium 2 at back. Medium 1 has 1 20,000 kg / s m , medium 2 has 2 15,000 kg / s m ,

both have thickness d1 d2 0.025 m .

3

In Figure 10 medium 1 has flow resistivity 1 50, 000 kg / s m and medium 2 has flow resistivity

2 15, 000 kg / s m3 and both have thickness equal to d1 d2 0.025 m . Because flow resistivity of

the medium 1 is more than 3 times of that of medium 2, characteristic impedances of those materials are

very different too.

Reflection Coefficient, R

1

Multi 2-1

Single 1

Multi 1-2

Single 2

0.8

0.6

0.4

0.2

0

500

1000

1500

2000

2500

3000

Frequency, Hz

3500

4000

4500

5000

Absorption Coefficient,

1

0.8

0.6

0.4

0.2

0

500

Figure 10.

Multi 2-1

Single 1

Multi 1-2

Single 2

1000

1500

2000

2500

3000

Frequency, Hz

3500

4000

4500

5000

Comparison between reflection and absorption coefficients of 2 different multilayered media obtained using Delany-Bazley

3

3

model. Legend as Figure 9. Medium 1 has 1 50,000 kg / s m , medium 2 has 2 15,000 kg / s m , both have thickness

d1 d2 0.025 m

Flow resistivity is a measure of how much resistance a porous material offers to the passage of air for a

given gradient of pressure and it is proportional to the amount of energy that is dissipated from viscous

effects. It is therefore clear that material with higher flow resistivity has also higher absorption

properties. The multilayer with medium 1 (higher absorption) placed at the back performs better than the

other one in terms of absorption.

3. Using available materials in the lab, find the material with the highest attenuation coefficient at 1 kHz.

References

[1] British Standards, “Acoustics — Determination of sound absorption coefficient and impedance in

impedance tubes —Part 1: Method using standing wave ratio”, BS EN ISO 10534-1, 2001.

[2] British Standards, “Acoustics — Determination of sound absorption coefficient and impedance in

impedance tubes —Part 2: Transfer-function method”, BS EN ISO 10534-2, 2001.

[3] Allard, J.F. and Atalla, N., “Propagation of Sound in Porous Media: Modelling Sound Absorbing

Materials”, Second Edition, Wiley, 2009.

[4] Chung et al., “Transfer function method of measuring in-duct acoustic properties. I. Theory”, J. Acoust.

Soc. Am., 68, 907-913, 1980.

[5] Chung et al., “Transfer function method of measuring in-duct acoustic properties. II. Experiment”, J.

Acoust. Soc. Am., 68, 914-921, 1980.

[6] Utsuno et al., “Transfer function method for measuring characteristic impedance and propagation constant

of porous materials”, J. Acoust. Soc. Am., 86, 637-643, 1989.

[7] Smith C. D. and Parrott T. L., “Comparison of three methods for measuring acoustic properties of bulk

materials, J. Acoust. Soc. Am., 74, 1577-82, 1983

[8] Song B. H. and Bolton J. S., “A transfer-matrix approach for estimating the characteristic impedance and

wave numbers of limp and rigid porous materials”, J. Acoust. Soc. Am., 107, 1131-52, 2000.

[9] M. E. Delany, E. N. Bazley, “Acoustical properties of fibrous absorbent materials”, Applied Acoustics, 3,

105-116, 1970.

[10] Dunn, I. P. and Davern, W. A., “Calculation of acoustic impedance of multilayer absorbers”, Applied

Acoustics, 19, 321-34, 1986.

[11] Miki, Y., “Acoustical properties of porous materials – Modifications of Delany–Bazley models”, J. Acoust.

Soc. Japan, 11, 19-24, 1990.

[12] Fellah Z.E.A. et al., “Measuring the porosity and the tortuosity of porous materials via reflected waves at

oblique incidence”, J. Acoust. Soc. Am., 113, 2424-33, 2003.

[13] Umnova O. et al., “Deduction of tortuosity and porosity from acoustic reflection and transmission

measurements on thick samples of rigid-porous materials”, Applied Acoustics, 66, 607–624, 2005

[14] Turo D. and Umnova O., Flow resistivity rig: Project at the University of Salford, 2010.

[15] BS EN 29053 “Acoustics — Materials for acoustical applications. Determination of airflow resistance”,

1993.

[16] Attenborough, K. “The prediction of oblique-incidence behaviour of fibrous absorbents”, J. Sound Vib., 14,

183–91, 1971.

[17] Attenborough K., ‘‘Acoustical characteristics of porous materials’’ Phys. Rep., 82, 179-227, 1982

[18] Burke, S. “The absorption of sound by anisotropic porous layers”. Paper presented at 106th Meeting of the

ASA, San Diego, CA, 1983

[19] Nicolas and Berry 1984,

[20] Allard, J.F., Bourdier, R. & L’Espe ́rance, A., “Anisotropy effect in glass wool on normal impedance in

oblique incidence”, J. Sound Vib., 114, 233–8, 1987.

[21] Tarnow, V., “Dynamic measurement of the elastic constants of glass wool”, J. Acoust. Soc. Am., 118, 36723678, 2005.

[22] Champoux et al., “Air-based system for the measurement of porosity”, J. Acoust. Soc. Am., 89, 1991.

[23] Beranek L. L., “Acoustic Imedance of Porous Materials”, J. Acoust. Soc. Am., 13, 248-260, 1942

[24] R. W. Leonard, ‘‘Simplified porosity measurements,’’ J. Acoust. Soc. Am., 20, 39–41, 1948

Matlab codes

Characteristic impedance and wavenumber measurement: two thickness method

% Characteristic impedance measurement

% Define constants:

freq = [];

rho = 1.21;

c = 343;

s = 0.1;

Zair = rho*c;

k = (2*pi*freq)/c;

d = ?;

% frequency vector (Hz)

% density of air (kg/m^3)

% speed of sound in air at 23 Celsius (m/s)

% microphone spacing (m)

% characteristic impedance of air (kg/m^2/s)

% wavenumber in air (m^-1)

% sample thickness (m)

% Characteristic impedance

Zc = sqrt(Zs1.*(2.*Zs2 - Zs1));

% Zs1 is surface impedance of the sample “d” meters thick

% Zs2 is surface impedance of the sample “2d” meters thick

Q = sqrt((2.*Zs2 - Zs1)./Zs1);

kc = 1/2/j/d.*log((1+Q)./(1-Q));

figure(1)

subplot(2,1,1)

plot(freq,real(Zc),'b','LineWidth',2)

xlim([0 1600])

title('Characteristic Impedance - Real part','FontSize',12)

xlabel('Frequency (Hz)')

grid on

subplot(2,1,2)

plot(freq,imag(Zc),'b','LineWidth',2)

xlim([0 1600])

title('Characteristic Impedance - Imaginary part','FontSize',12)

xlabel('Frequency (Hz)')

xlim([0 1600])

grid on

figure(2)

subplot(2,1,1)

plot(freq,real(kc),'b','LineWidth',2)

xlim([0 1600])

title('Wavenumber – Real part','FontSize',12)

xlabel('Frequency (Hz)')

grid on

subplot(2,1,2)

plot(freq,imag(kc),'b','LineWidth',2)

xlim([0 1600])

title('Wavenumber – Imaginary part','FontSize',12)

xlabel('Frequency (Hz)')

grid on

Characteristic impedance and wavenumber measurement: two cavity method

% Characteristic impedance measurement

% Define constants:

freq = [];

rho = 1.21;

c = 343;

s = 0.1;

Zair = rho*c;

k = (2*pi*freq)/c;

L1 = ?;

L2 = ?;

% frequency vector (Hz)

% density of air (kg/m^3)

% speed of sound in air at 23 Celsius (m/s)

% microphone spacing (m)

% characteristic impedance of air (kg/m^2/s)

% wavenumber in air (m^-1)

% air gap 1 depth (m)

% air gap 2 depth (m)

% Air gap surface impedance

Z1_1 = -j*Zair*cot(k.*L1);

Z1_2 = -j*Zair*cot(k.*L2);

% Characteristic impedance

Zc = sqrt( ( Z0_1.*Z0_2.*(Z1_1-Z1_2) - Z1_1.*Z1_2.*(Z0_1-Z0_2) )./( (Z1_1-Z1_2) - (Z0_1-Z0_2) ) );

% Z0_1 is surface impedance of the sample with air gap 1

% Z0_2 is surface impedance of the sample with air gap 2

kc = 1/2/j/d.*log( (Z0_1+Zc)./(Z0_1-Zc).* (Z1_1-Zc)./(Z1_1+Zc) );

figure(1)

subplot(2,1,1)

plot(freq,real(Zc),'b','LineWidth',2)

xlim([0 1600])

title('Characteristic Impedance - Real part','FontSize',12)

xlabel('Frequency (Hz)')

grid on

subplot(2,1,2)

plot(freq,imag(Zc),'b','LineWidth',2)

xlim([0 1600])

title('Characteristic Impedance - Imaginary part','FontSize',12)

xlabel('Frequency (Hz)')

xlim([0 1600])

grid on

figure(2)

subplot(2,1,1)

plot(freq,real(kc),'b','LineWidth',2)

xlim([0 1600])

title('Wavenumber – Real part','FontSize',12)

xlabel('Frequency (Hz)')

grid on

subplot(2,1,2)

plot(freq,imag(kc),'b','LineWidth',2)

xlim([0 1600])

title('Wavenumber – Imaginary part','FontSize',12)

xlabel('Frequency (Hz)')

grid on