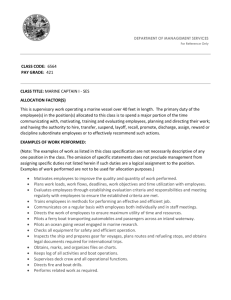

x2 construct

advertisement

Submaran – An Autonomous Unmanned Marine Vessel An Autonomous Unmanned Marine Vessel: Low-Cost In-situ Information Gathering on the World’s Oceans with Ultra-Long Range and Endurance Ocean Aero, Inc. May 2013 1 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Contents Introduction………………………………………………………………………………… 3 The Need for a Highly Persistent Maritime Sensor Platform…………………………. 3 The Unmanned Vehicle as an Ocean Observation Platform………………………… 4 The Ocean Aero USV/UUV Solution – The UUSV……………………………………. 6 Unmanned Vehicle Utility and Merit Comparison……………………………………… 7 UUSV Technical Description…………………………………………………………….. 7 Specifications…………………………………………………………………….. 7 Wingsail…………………………………………………………………………… 8 Vessel Platform………………………………………………………................. 9 Vessel Control and Communications………………………………………….. 9 Energy Production and Storage.……………………………………………….. 9 UUSV Modes of Operation……………………………………………………………… 10 Surface………………………………………………………............................. 10 Semi Submerged……………………………………………………….............. 11 Submerged………………………………………………………....................... 11 Development Plan……………………………………………………………………….. 12 Summary………………………………………………………………………………..… 14 Appendix A – Unmanned Vehicle Utility and Merit Comparison Data……………… 16 Appendix B – Management and Technical Team…………………………………..… 18 2 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Introduction The purpose of this paper is to introduce Ocean Aero’s highly innovative autonomous unmanned marine vessel, propelled only by wind and sun that is both a surface and subsurface vessel. There is currently a strong demand within the commercial, scientific and government communities for long-term information gathering on the world’s oceans, both along coastlines and out to sea. Available systems, such as space satellites, manned ships, and manned/unmanned aircraft are expensive and/or offer unsatisfactory performance. Most satellites can make surface-water or very shallow-water measurements only and are incapable of marine biological monitoring or sampling. Manned ships are expensive to operate, limited to short terms and only make small area observations. Manned/Unmanned aircraft are expensive, limited to short terms and/or offer insufficient marine data collection capabilities. The present in-situ ocean observation/data base is largely incomplete, less than 5% of our oceans have been explored. Zdenka Willis, Director of NOAA’s IOOS Program Office has stated, “We know more about the surface of Mars than we do about this planets ocean”. Little is understood about the sea’s roll in global climate change and better data collection is becoming increasingly critical. Ocean Aero is developing "Submaran" - an innovative low-cost solution that among some of its key features promises long range, endurance and utility with reduced risk to personnel and impact on budgets. The Ocean Aero “Submaran” is a hybrid-unmanned vehicle that integrates the key functional and operational capabilities of a submarine and a surface sailing vessel. The Submaran is a compact, eight feet in length, 160-pound man portable vessel, powered solely by the wind and sun for propulsion, data collection and communications, with on board energy storage via lithium ion batteries. The vessel’s small size makes it is difficult to detect while operating on the ocean’s surface and nearly impossible to discover without sophisticated sensors when fully submerged. One of the vessel’s most unique and important operational capabilities is the ability to completely submerge during rough surface storm conditions, a tactic which enhances its survivability and durability. The “Submaran” is a resilient sea-surface and subsurface sensor platform that can self-deploy and operate to any global maritime location. The vessel will be able to collect valuable information from close in coast to the wide-open ocean, from the ocean’s surface down to depths of hundreds of feet. Ocean Aero has the expertise to develop this vessel based on its key engineering personnel’s experience in robotic sailing vessel technology, aerospace unmanned vehicle design and systems engineering. Their expertise, together with a team of business professionals familiar with marketing in the commercial and defense robotics industries will enable successful completion of development within cost and schedule parameters. Ocean Aero’s personnel include: Eric Patten – Over 30 years of maritime experience, including 25 years as US Naval Officer and surface and subsurface surveillance Helicopter pilot. Most recently Eric was the Director of Defense and Intelligence Marketing with ESRI. 3 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Ken Childress – Over 25 years of executive business experience in development and management of high-technology businesses. Ken has been involved in various projects ranging from product development and manufacturing to finance and merger. Mark Ott – 23 years’ experience in wind powered marine vessel engineering, engineering management, fabrication, including autonomous unmanned wind powered vessel research and development. Vance E. McClure PhD – Over 30 years’ experience in Aero Space engineering R&D. Vance has worked on many programs ranging from stealth technology to numerous manned and unmanned air and space vehicles. Patrick Wright Over 25 years of experience designing, building and testing advanced air vehicles, both manned and unmanned systems. Exemplified by engineering Project Management for Burt Rutan’s company; Scaled Composites and Paul MacCready’s AeroVironment. The Need for a Highly Persistent Maritime Sensor Platform The demand for coastal and open-ocean observation, research and Intelligence, Surveillance and Reconnaissance (ISR) is increasing throughout the world. The constant need for information by; scientists, oil and gas industry, defense, law enforcement and security in real time of what is occurring on or below the ocean surface has never been more important. The Submaran can address these needs, particularly in the following areas: Scientific Research The prohibitive cost of manned-ship scientific research and surveys in an era of shrinking government budgets will result in fewer vital scientific studies and ocean surveys being conducted. This research enables understanding of the complex interactions of our oceans with regards to critical global climate change, man-made pollution, food cycle production, overfishing, marine mammal observation, and ocean warming and acidifying. The rising cost of large ship maintenance and operations is having a significant impact on this vital research. The Submaran can do ocean surface/subsurface environmental monitoring, bathymetry, ocean chemical/biological and pollution sampling/analysis to name a few specific missions for Scientific Research at a lower cost, etc. Oil & Gas Industry The oil and gas industry spends on average $20,000 per square nautical mile for hydrographic, seismic reflection and other necessary surveys performed by expensive ships with high operational overheads. Localized ocean currents and other environmental data such as salinity, pollutants and hydrocarbons must be collected over long periods of time to aid in the engineering, construction and maintenance of offshore platforms. The Submaran can do sonar ocean floor mapping for exploration/construction, offshore platform/pipeline survey and maintenance and offshore platform/pipeline security for the oil and gas industry at 10 – 20 percent the cost of current methods and practices. 4 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Defense Navies perform ocean observation throughout the world, for missions such as mine warfare, anti-submarine warfare, oceanography and ISR (Intelligence, Surveillance and Reconnaissance). These Navy missions all require persistent maritime sensors, which are currently delivered using expensive manned ships and/or space assets. For example, foreign and potentially hostile navies are increasing their production of cheap, highly effective mines. According to the Navy’s 2009 report, “21st Century U.S Navy Mine Warfare; Ensuring Global Access and Commerce,” there are more than 300 types of sea mines produced by 30 countries and more than a quarter-million sea mines are held in the inventories of 50 navies around the world. Even more worrisome is the US militaries diesel/electric submarine threat requirement. Navy officials contend that an undersea arms race already has begun in the western Pacific. China is steadily increasing its diesel/electric fleet and now other Pacific Asian countries such as North Korea, Malaysia and Indonesia are following suit. In the Middle East, Iran threatens international access to strategic coastal areas and shipping lanes with floating mines & submarines capable of interrupting the flow of commerce throughout the region. The Submaran can address these types of issues be providing stealthy, selfprotected, network capable over large area eyes and ears to the Navy at reduced cost that completely removes sailors from danger.. Law Enforcement and Security In addition to utilizing surface vessels, organized crime has transitioned to transporting tons of illicit cargo (drugs and weapons) using fully submersible submarines. These vessels are increasingly difficult to detect, making them the preferred method for moving large amounts of illegal cargo. In addition to their submersibles, organized crime continues to smuggle drugs, weapons and human cargo across the oceans – often done during periods of low observation (i.e. between patrols etc.). Unregulated illegal poaching of fisheries by commercial fishing vessels have severely depleted the world’s fish stocks, which have been steadily declining since 1980. Blue-fin tuna stocks, a favorite of Japanese consumers, are collapsing globally at an alarming rate and scientists argue it may already be too late to save the species from extinction. Vital infrastructure like commercial ports, offshore oil platforms, pipelines, communication lines, as well as coastal nuclear power plants are high-risk targets and as a result increased water security is essential. Piracy has continuously increased for the past 12 years and is spreading outward from Somalia throughout the Middle East and into the Asian Pacific regions. Maritime piracy is estimated to cost the international economy $7 to $12 billion per year. The Submaran can help address these issues by providing real time monitoring of human activities utilizing its water transmitted sound as well as day or night optical sensors. 5 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel The Unmanned Vehicle as an Ocean Observation Platform The current state of unmanned vehicles serving as ocean observation platforms includes the following: Unmanned Air Vehicles Unmanned Surface Vessels Unmanned Underwater Vehicles This variety of unmanned vehicles is currently used to perform coastal and open ocean ISR. A number of unmanned aircraft designs perform the role of “eyes in the sky” at altitudes ranging from hundreds of feet to tens of thousands of feet above ground. Unmanned surface vessels are being developed for a myriad of tasks including; environmental monitoring and sampling, bathymetry, mine hunting, anti-submarine, bottom mapping and communications relay missions. These unmanned underwater vehicles have been in development since 1957, and now perform a number of military, commercial and scientific data gathering missions. All these systems prevent people from being put in harm's way and have varying degrees of cost savings. Unmanned Air Vehicles (UAVs) are the most well-known intelligence gathering robots due to their successful use by the United States military in the recent wars in Iraq and Afghanistan. Outfitted with cameras, electro optics, infrared and other sensors, they are proven ISR platforms. UAVs greater challenge is locating targets over vast expanses of ocean in all types of weather and sea conditions (i.e. hurricanes). To avoid this weather, these aircraft must be able to fly high enough to get above storms making it difficult for the sensors to see useful images of smaller objects on the surface in rough conditions. In addition, the higher the UAV’s flight ceiling and effective sensor capability, the more expensive the technology becomes. Moreover, with the need to patrol large expanses of ocean, UAV’s are challenged by their ability to carry enough fuel to loiter long enough (sometimes days or weeks) or patrol areas large enough to provide the ability to meet mission requirements. Unmanned Surface Vehicles (USVs) are in the early stages of development in comparison to their aerial counterpart (UAVs). Most designs simply modify or adapt a manned vessel to become a robot. Most of the current USV designs use either gas or diesel marine engines, making their mission duration times limited to a maximum of a few days and hundreds of miles at best. Unmanned automatic refueling station designs are now being produced but this approach raises a number of questions, including “Who is responsible for refueling the unmanned fuel stations?” Over the last decade, less than two-dozen different USV designs have emerged and only a few have been operationally deployed, including Israel’s Navy’s “Protector” USV, a standard 30 ft. rigid-hulled inflatable boat. “Protector” is used as a security asset for port and ship protection, carrying cameras, surface radar and a 50-caliber machine gun. It is diesel powered and therefore limited in range and on station time. In addition to the Protector, Liquid Robotics (LR) has deployed a long range and persistent USV. The LR Wave Glider is unique in the USV environment using a long umbilical cord attached to the propulsion unit that uses wave power for propulsion. Though this type of propulsion provides long range and persistence, it is significantly limited to a maximum of ~1.5 knots without other forms of additional propulsion. The speed and configuration puts significant restrictions on how and where the vessel can be deployed. Overall, USVs are well suited in providing an ocean observation platform and can efficiently 6 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel move through the water at both high and low speed with tradeoffs for power and endurance. Unmanned Underwater Vehicles (UUV) have been in development for over 50 years and hundreds of designs have emerged. There are two basic types of UUV’s, engine driven or buoyancy driven, the later more commonly known as “gliders”. Underwater vehicles have the advantages of being able to effectively use SONAR to listen for sound transmitted thru the water at varying depths making them good platforms to locate and identify surface vessels as well as submarines and conduct sea bottom observation. Outfitted with specialized payloads such as compact acoustic and magnetic mine sensors, they can locate and neutralize tethered or buried mines on the sea floor. UUVs are unaffected by adverse weather conditions, as they normally operate below the frequently turbulent water surface. Similar to manned submarines, they are also extremely difficult to detect, therefore well suited for covert missions. The principal engineering challenges for UUVs, especially the gliders, are that they typically travel at very low speeds (between one to three knots), making navigation in stronger ocean currents difficult. Engine driven UUV’s have very limited space for fuel and/or stored electrical energy, mission duration times are measured in hours rather than days burdening them with high manned operational requirements and expenses. Solutions to these limitations are being sought by designing much larger or scaled up vehicles, storing more batteries or fuel to produce greater propulsion and endurance. The Ocean Aero USV/UUV Solution – The UUSV Over the last six years, members of the Ocean Aero Team built autonomous unmanned wind powered surface vessels for the Navy. These implemented designs were operated in winds ranging from 2 to 50 knots. These vessels autonomously sailed multiple waypoint courses over 9 nautical miles long in six-foot seas and 30 knots of wind, producing cross track errors of less than 3.5 meters. Submaran wingsail deployed deck view 7 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel During this six year developmental period, repeated interest was expressed by several potential government and commercial customers in an easily transportable small primarily wind driven USV concept. Our Ocean Aero “Submaran” solution is in response to customer needs for low unit and operational costs. By enabling reduced costs, Ocean Aero aims to open up the technology to a broader market and allow for deployment of USV’s in large networking groups, or “swarms”, over wide areas to perform specialized tasks. Ocean Aero identified that one of the more significant challenges in engineering a small USV design was to be able to maintain stability and seaworthiness in harsh surface conditions during storms. Since a small vessel is vulnerable to capsize or damage by breaking waves and high sea states, Ocean Aero determined through design analysis that a vessel could spend more time trying to right itself in heavy seas than continuing to perform its mission, or worse, be damaged by wave action. This led our company to conclude that the best way for the vessel to effectively deal with larger waves was for it to have the ability to partially or fully submerge beneath waves depending on real-time conditions. This ability to submerge also increases mission areas and allows for wider tactical applications. UUSV Technical Description Specifications Length: 8 ft. Height: 7 ft. (wingsail up) Draft: 32 in (maximum – keel deployed) Platform weight: 125 lbs. Payload: up to 35 lbs. Total Weight: 160 lbs. Payload Power: 300 watts, peak Unmanned Underwater Surface Vehicle is broken down into four major components: 1. Wing sail 2. Vessel Platform 3. Vessel Control and Communications 4. Energy Production and Storage Wingsail The wingsail assembly is a hard surface, all composite airfoil similarly shaped to airplane wings standing vertically erect on the boat. The assembly is fabricated entirely from composite materials and engineered to withstand the harsh conditions of waves breaking over the top of it. Composites, impervious to salt water and corrosion, strong, lightweight and engineered to have low electromagnetic and visual cross sections. The wingsail assembly has a symmetrical main leading wing that creates thrust from the wind. Trailing behind the main wing, mounted on control arms is a symmetrical flap airfoil. The flap can be cambered either left or right of the main wing creating a higher lift coefficient depending upon port of starboard point of sail. A round mast section supports the wingsail assembly from top to bottom. At the wingsail’s base control belts link to a hydraulically operated motor, which precisely controls the direction of the main wing, therefore regulating the amount of thrust the wingsail assembly produces directly from the wind. The wingsail assembly is balanced about the rotational axis of the mast, so it spins easily even in light winds. 8 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel The entire wingsail is fully cantilevered and rotates 360 degrees independently of the vessels hull. The wingsail is mounted on composite bearings and the mast is affixed to the folding mechanism, which can lower the entire wingsail assembly backward 90 degrees into a slot on the vessels deck. This unique feature effectively hides the wingsail from overpowering winds and assures that the vessel has low hydrodynamic drag during underwater operations. The wingsail stands six feet high when erect with a VHF communication antenna, anemometer, LED navigation light and a 360-degree Electro Optical and Infrared camera mounted on top. Submaran surface operation configuration Vessel Platform The composite hull of the UUSV is eight feet long with an overall platform width of 19 inches, drafting only 32 inches and having a designed total displacement weight of 160 lbs. Buoyancy changing water ballast systems are located at the bow and stern of the hull. Precise distribution of the UUSV’s center of buoyancy by shuttling water back and forth between fore and aft tanks will enable underwater propulsion termed “gliding.” A horizontal glider style airfoil is mounted to the vessels deck amid ship to provide the thrust necessary during underwater operations. Both the deck and the upper portion of the glider wing will be covered with one square meter of solar cells. Located inside the hull are twin redundant hydraulic control rams that simultaneously lower the sailing bulb keel and raise the wingsail assembly. The bulb keel will provide vessel fore and aft 9 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel stability, supply a counterforce to the wingsail’s side thrust component and provide vessel self-righting capability during rough sea sailing conditions; twin redundant steering rudders are located at the stern of the vessel that control directional heading during surface and subsurface operations. Vessel Control and Communications A hydraulic motor, located inside the hull, is positioned next to the wingsail assembly. The angle of attack of the flap airfoil is also controlled with the hydraulic motor coupled to a slave servo mounted inside the wingsail at its base. The UUSV’s processor controls the wingsail by input from a solid-state sonic anemometer mounted at the top of the wing as well as from data supplied by Global Positioning System and Inertial Navigation Sensor (INS). The INS units mounted inside the hull near the vessel’s center of gravity monitors the vessel’s roll, pitch, yaw and acceleration/deceleration. The masthead anemometer supplies the processor with data concerning wind speed and direction combined with a sonic sensor that measures boat speed through the water. This control architecture assures that the wingsail will never over or under power the vessel based on commanded speeds and preset vessel safety parameters. The platform is steered by twin rudders working in unison but driven independently by hydraulic servos located inside hull. This rudder arrangement provides redundancy for a critical vessel control function. Twin redundant electrically driven jet drive systems, with vectoring thrust for auxiliary surface and underwater propulsion, are located inside the hull at the stern. The hull also contains the following: wingsail/keel mechanical folding mechanism, water ballast systems, energy storage and power management, low pressure hydro/electric pump, hydro/electric distribution valve body processors, VHF radio, Iridium phone, INS/GPS, passive hydrophones and payload sensor bays. A VHF antenna is located at the top of the wingsail’s mast and an Iridium satellite antenna is mounted on deck. A Controller Area Network (CAN) wiring bus is used for the electronics system architecture because of its standardized, robust simplicity. 10 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Submaran bottom view Energy Production and Storage With no on board fossil fuels, the key to the UUSV’s high degree of mission persistence is its ability to collect and scavenge energy from the surrounding environment and use it for propulsion or store it in its batteries. The UUSV’s wingsail will efficiently convert wind energy directly into thrust allowing the vessel to sail up to one half of the true wind speed – with an engineered maximum speed of 6 knots. The vessels platform provides 1 square meter of mounting area for solar cells of which more than half can be exposed to the sun all the time. Assuming an average solar incidence angle for the un-occluded panels of 45 degrees, the effective normal area is approximately over one third meter squared. During a five hour day of insolation, high-quality gallium indium phosphide (GaInP) solar cells will be able to add a 440 Watt hr/day charge to the batteries on the surface decreasing with depth to about 15 Watt hr/day in 29 ft. of clear water. State of the art Lithium Ion batteries in the hulls will total at least 5 Kw / hr at an energy density of 700 W/hr/Liter. Increased battery capacity is easily accommodated since battery mass helps provide ballast for subsurface operations. 11 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Submaran deck solar panel areas UUSV Modes of Operation The vessels modes of operation are: 1. Surface 2. Semi Submerged 3. Fully Submerged Surface When the vehicle is in surface mode it can sail prolonged periods of time from energy supplied by the wind alone. The UUSV will travel at approximately one half of the speed of the wind up to a top speed of 6 knots. Higher speeds, although attainable, will be governed to create a safety margin. If no wind is present, the vessel can hold station or maneuver using its auxiliary electric water jet drives. As previously discussed, the vessels roll, pitch, yaw, acceleration/deceleration are monitored by the INS/GPS and course can be adjusted to increase stability or take advantage of wave energy. The ballast system can be used to increase the stability of the vessel while sailing. The anemometer on top of the wingsail continuously analyzes the wind speed and direction and allows the processor to adjust and optimize the wingsail’s thrust; precisely maintaining set commanded courses and speeds. The INS/GPS unit supplies exact location and speed allowing for the UUSV’s to have a cross track error of less than three meters while in surface sailing mode. 12 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel UUSV Surface Configuration Semi-Submerged In semi-submerged mode, the vessel’s hull is partially flooded by the water ballast systems so that the UUSV can sink to a controlled depth of 1 to 3.5 feet. In this state, the vessel becomes substantially more stable when encountering rough surface conditions and has low visibility if required. As the ballast systems take on water and the UUSV starts to submerge, the wingsail is held in position down the centerline of the vessel presenting as low a drag profile to the water as possible. Only the mast top 360degree view camera, environmental sensors and antennas project above the surface in semi-submerged mode. The solar cells, being tuned to the blue-green light spectrum, will remain fully functional in semi-submerged mode as well. Fully Submerged As the UUSV continues to take on water ballast and submerge below 4 feet, the wingsail is folded down towards the stern and locked in this position by its lowering and lifting control ram. As the control ram is lowering the wingsail, the keel is simultaneously pivoted in a scissoring motion upward. The lowering of the wingsail and pivoting of the keel reduces the hydrodynamic drag of the vessel while in fully submerged mode, enhancing maneuverability and conserving energy. The rudders act as elevons and in conjunction with the ballast system, and the underwater glider wing control the boats underwater pitch, roll and yaw attitudes. The rudders also regulate the vessel’s underwater heading and by supplying vectored thrust from the jet drives underwater maneuvering can be enhanced. The vessel will have a top speed fully submerged of 13 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel two knots in glider mode and four knots using the auxiliary jet drive. The UUSV’s initial designed operational depth will be 75 feet (generation 1) with a subsequent version’s capable of 650 feet (200 meters). In fully submerged mode the boat will be able to completely avoid harsh storm conditions and be virtually undetectable from the surface. The UUSV’s ability to go from surface to fully submerge in less than one minute will provide a self-defense mechanism from attack, piracy or being overrun by larger vessels. With the technological evolution of solar panels that are able to collect energy down to 29 feet and by employing glider UUV buoyancy changing technology, the vessel’s subsurface operations time will be exceptionally long. Persistent underwater station keeping coupled to passive sonar will provide highly effective subsurface and surface vessel detection capability while the UUSV remains completely hidden . UUSV in Submerged configuration 14 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Solution Implementation Plan Ocean Aero is implementing a structured engineering methodology to develop our Submaran solution. The four key phases of our methodology include: Design and create full scale build to print drawings Build and begin testing first prototypes utilizing COTS radio controlled equipment Advanced testing in varied conditions up to and including predicted operational limits Analyze prototype testing, modify design as need be to meet all requirements then design build and test pre-production prototype Applying best practices of project management; Ocean Aero has established a planning baseline that includes a Requirements Specification, WBS Schedule, Critical Path Analysis, Basis of Estimates, Budget, Roles and Responsibilities Matrix, Risk Assessment, Performance Metrics, and Monthly Project Reviews. Our basis of estimate includes cost optimization by integrating into the first prototype unit off-the-shelf radio controlled model sailing and submarine equipment and initially conducting tests in an enclosed pool environment. Phase I - Full-Scale Prototype. This will begin with an engineering study of all the vessels major control components and subsystems. A complete 3D Computer Aided Design (CAD) of the UUSV will be generated taking into account an overall vessel weight budget as well as aero/hydrodynamics which will dictate the hull wingsail glider foil and rudder foils shape and areas necessary to achieve performance predictions. Build to print engineering drawings will be developed from the CAD program. The timeline for Phase I is estimated below: Engineering Task Generate Baseline Requirements, Concept Engineering (platform), Design Full Scale Prototype Days to Complete 60 Build to Print Engineering Drawings 15 Generate Baseline Requirements, Concept Engineering (wingsail), Design Full Scale Prototype 30 Build to Print Engineering Drawings 15 Hardware Integration 20 The total amount of time necessary to complete phase I is 2 months as some of the engineering tasks can be completed simultaneously. 15 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel In Phase II - A full-scale prototype will be constructed and outfitted with off-theshelf model radio controlled ‘RC’ surface boat and submarine hardware. The fully assembled UUSV will be bench tested for proper servo and mechanical operation. Field-testing of the prototype will use an incremental procedure with initial water trials taking place in a swimming pool. The pool will offer a controlled and easily observed development environment. Performance data will be collected in all three modes of operation, thoroughly analyzed and modifications or adjustments performed as necessary. The timeline of phase II is estimated below: Fabrication and Materials Platform Wingsail Hardware/Installation Days To Complete 30 30 15 Engineering Task Enclosed Pool Testing/Requirements Analysis, Re-Design, Re-Test Days To Complete 90 The total amount of time necessary to complete Phase II is four months. Phase III - Operational Testing of the prototype will be initiated using protected ocean waters then will be moved into the open ocean. Progressively higher sea state operations will be conducted up to and including breaking wave conditions. Data will be collected in the three modes of operation, thoroughly analyzed and modifications or adjustments performed if necessary. The timeline of Phase III is estimated is approximately 4 months as described below: Engineering Task Protected Water Testing Open Ocean Testing/Requirements Analysis, Re-Design, ReTest Days to Complete 30 30 Phase IV - A finalized prototype hull, keel and wingsail will be built. The phase III the RC hardware will be replaced with processor driven hydro/electric motors, servos and controllers that are CAN bus enabled. A wiring harness will be engineered, fabricated and installed. The batteries will be replaced with optimized high efficiency technology along with inclusion of a charging/regulating system. The vessel will be equipped with solar cells capable of operating at depths up to 29 feet VHF marine radio and Iridium communication systems will be installed in the hull along with a hydraulic pump, hydraulic valve body, hydrophones, ballast pump and tanks. An INS/ GPS system for navigation will be included and antenna placed on deck. A 360-degree view camera will be located on top of the wingsail and an image processor included in the hull. Computer algorithms will be written for control, navigation, communications, vehicle health/energy management and input sensor operations. All electronic, hydraulic and mechanical systems will be thoroughly bench tested before returning to the water. The UUSV will then be re-tested using the same procedure as in the earlier phases, starting with enclosed pool operations. After the 16 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel successful completion of the all the initial water testing a series of ocean dives up to the maximum depth of 75 feet will be conducted. Finally, extended range, duration and collision avoidance testing will be undertaken. At the end of Phase IV a 10 month timeframe, an analysis of the project will be generated documenting the entire program to date containing conclusions, lessons learned and recommendations for the building of the first production prototype. Project Schedule Overview - 18-Month Project Plan 17 X1 - Complete Internal Build to Print Drawings of Performance & Handling Full Scale Model = month 3 X1 - Performance & Handling Full Scale Model Built and ready to begin on-thewater testing = month 5 X2 - Complete Internal Build to Print Drawings of Demonstration Prototype Full Scale Model = month 8 X2 - Demonstration Prototype Full Scale Model Built and ready to begin on-the water testing = month 12 PP - First Production Prototype Built: Ready for testing and collection of data for first customers = month 18 UV - Underwater/Surface (UUSV) capability planned for 6 months after surface only version = month 24 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Unmanned Vehicle Utility and Merit Comparison To demonstrate how our Submaran design would improve unmanned vehicle ocean ISR capabilities, Ocean Aero conducted research to examine the advantages and disadvantages of existing UUV, UAV and USV designs. The results of the study are shown in the following graph (with more extensive data tables in Appendix A). The Ocean Aero, Unmanned Underwater/ Surface Vehicle (UUSV) could match or exceed most other vehicles design performance in every category with the exception of unmanned aircraft achieving greater transit speed. The scoring of the vehicles is arranged from poor = 1 to best = 4. Ocean Aero has designed its vessel to take advantage of the strengths and address the weaknesses of the different classes of unmanned vehicles (UUVs, UAVs, and USVs) that currently perform ocean ISR missions. Many of the advantages of each can be utilized and the disadvantages mitigated by combining surface and subsurface vehicles into a single design: the Unmanned Underwater Surface Vehicle (UUSV). Vessel/Propulsion Type 1) UUSV/Wind, Electric Submersible Buoyancy 2) UUV/Buoyancy 3) UUV/Electric 4) USV/Wave 5) USV/Wind & Electric 6) UAV/Gas 7) USV/Gas Summary The Ocean Aero UUSV will be the first robotic vehicle to have the ability to transition quickly between surface wind powered vessel and underwater submarine. It will have extremely long mission duration and distance persistence as a result of its selfpowering capabilities. On the surface, the vessel will be able to transit any distance 18 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel required (similar to a sailing vessel) using little to no stored energy. Fully submerged or semi-submerged it can covertly hold station or loiter at shallow depths for extremely long periods of time. The vessel will be an excellent candidate to be used in large networked groups (swarms) covering widespread areas of ocean due to its low production cost and compact size. A successful outcome of the project is assured with the experienced team of engineers that has been assembled. The team has significant Defense/Aerospace experience between them including several individuals; Vance E. McClure and Michael Matarrese with engineering doctorates. The UUSV will define a new class of multipurpose unmanned autonomous ocean vehicles, setting benchmarks in design and engineering for years to come. The “Submaran” UUSV 19 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel About Ocean Aero We published this white paper to help government, oil and gas, and the scientific communities understand the benefits of long range, persistent unmanned systems that provide low cost in-situ information gathering on the world’s oceans. To find out more about more about “Submaran” and Ocean Aero, feel free to contact us at 858-945-3768 or email us at eapatten@oceanaero.us Ocean Aero, Inc. 2877 Historic Decatur Dr, Suite 200 San Diego, CA 92106 20 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel APPENDIX A –(REFERED TO IN DOCUMENT) Unmanned Vehicle Utility and Merit Comparison Chart UUSV UUV UUV USV USV UAV USV Sub Sail + aux Power Sub “Buoyancy Glider” Sub Power Surface Sail + aux Power Surface “Wave Glider” Aircraft Surface Power Submarine Sail + aux Power (UUSV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Submarine Glider (UUV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Submarine Power (UUV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data 21 Total Score 22 20 Poor (1) Fair (2) 17 17 16 16 14 Good (3) Best (4) 22 Poor Fair Good Best 1* 20 Poor Fair Good Best 2* 17 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Surface Sail + aux Power (USV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Surface Wave Glider (USV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Aircraft (UAV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Surface Power (USV) Transit speed Transit range Station keeping Sea state survival Stealth Marine data Poor Fair Good Best 17 Poor Fair Good Best 3* 16 Poor Fair Good Best 2* 4* 16 Poor Fair Good Best 2* 14 NOTES: 1. 2. 3. 4. 22 Limited by ocean current speed Limited by fuel/energy storage Fouling of cables between surface and paddle assembly Weather limitations: altitude, sensors trade offs Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel APPENDIX B The Management Team Eric Patten, CAPTAIN USN (Ret). - President eapatten@oceanaero.us Education BA Political Science, Washington State University, Pullman WA MA, National Security and Strategic Studies, US Naval War College, Newport RI Prior to joining Ocean Aero, Eric was the Director, Defense and Intelligence Global Solutions for the geospatial technology leader Esri, were he lead his team to build awareness of Esri's geospatial technology within the defense and intelligence communities worldwide. Before joining Esri in 2010, Eric served as a US Navy Captain with a 25-year career of distinguished service. He was the Director of operations for the US Navy's Southwest region, responsible for shore-based operations including those supporting anti-terrorism, fire and emergency services, emergency management, and air and port operations. He served as navigator aboard the USS Ronald Reagan on several deployments including its maiden deployment to the Middle East in support of the global war on terrorism. Eric was the commanding officer of Helicopter Anti-Submarine Squadron Five One in Japan and has held several posts on a number of naval vessels. He also led combat missions as a naval aviator. Mark Ott – Founder/Chief Technical Officer mtott@oceanaero.us Harbor Wing Technologies Inc. 02/2002 – 09/2012 Founder/EVP Engineering & Project Management Mark has many years of experience as a multi-hull boat designer, builder and competitive sailor with extensive open ocean sailing and racing experience. Mark’s early multi-hull creations were the starting point for the design and development of currently the world’s most sophisticated automated wing-sail assemblies and wind driven surface vessels. While with Harbor Wing Technologies, Mark managed and coordinated all aspects of design, engineering and systems integration for a world class technical team under contract to the U.S. Navy, Carderock Surface Warfare Center. The team’s research and development led to the creation of the world’s first primarily wind driven autonomous unmanned surface vessel. Under Mark’s direction, over a period of six years, the team successfully demonstrated to Navy program management several iterations of these multi-hull, wing-sail driven designs. Mark is the co-creator and inventor on several U.S. patents inspired during the engineering process. Mark along with Bud McClure developed the Ocean Aero UUSV concept. Ken Childress – Founder/Executive Vice President kenc@oceanaero.us Education University of Utah, School of Business Ken brings to the company more than twenty years of executive business experience in developing and managing high-technology businesses. In his capacity as Executive VP of Business Development for Harbor Wing Technologies, he was responsible for shaping and delivering the company’s message to potential users of its technology, interacting with the media and financial communities as well as managing overall marketing and business partnerships. He was also responsible for intellectual property development, which helped to produce three patents and several trademark registrations. His experience includes many years of working in marketing, management and business development for top Silicon Valley technology companies including 23 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Cisco Systems and Redback Networks. In addition, Ken has been involved in various projects ranging from product development and manufacturing to finance and merger. He is now focusing his wide range of business experience on the development Ocean Aero’s innovative marine systems and alternative energy products. The Technical Team Vance E. (Bud) McClure, Ph.D. – Head Engineer Education Post Doctoral Fellow, Scripps Institute of Oceanography, La Jolla, CA. PhD in Physical Chemistry, University of California, San Diego, CA. BS Chemistry, minors in Mathematics and Physics, University of California, Riverside, CA. AB Chemistry, The Principia College, Elsah, Illinois. Bud began his professional engineering career with a National Science Foundation Traineeship that included his thesis work in quantum mechanics and group theory of bonding in intermetallic compounds, molecules, complex ions and nuclei. He later worked for over 18 years as a senior scientist with Burt Rutan’s company, Scaled Composites, LLC., solving problems such as aerothermal analysis for SpaceShipOne (SS1) and SS2 boost and re-entry thermal protection. Bud has exemplified the dedication and leadership required to engage in highly complex research, development and engineering across a broad range of aeronautical engineering, design, thermodynamic, molecular and material sciences. A brief summary of his extensive scientific resume includes work done at McDonnell Douglas Technologies as Principal Investigator for IR&D projects which involved experimental and theoretical re-search into the interaction of radiation with matter. He also led code development for visible and infrared scene modeling and vehicle signature analysis at PAR Government Systems Corp. Bud’s additional work for Scaled Composites included but was not limited to: Structure optimization codes for liquid propellant launch vehicles, fire burn-over model and thermal design of fire shelters for personnel and vehicles and solar heating / aero cooling models for aircraft structures, fuel tanks and crew cabins. Recently, as principal of his own consulting practice, Bud designed the spacesuit-capsule interface, capsule life support system, electronics thermal control systems, and wrote mission simulation and control software for a ballo on ascent and parachute jump from 130,000 ft. for the RedBull Mission to the Edge of Space Project. In addition, Bud has authored a score of manuscripts and published writings on complex topics such as: “Refraction of inhomogeneous waves in lossy anisotropic materials", “Heat exchange in fluids having temperature dependent heat capacity", and “Transport of heavy chlorinated hydrocarbons in the atmosphere”. Patrick Wright – Overall Engineering Program Manager Education BS, Aeronautical Engineering, Texas A&M University, Patrick brings to the company 25 years of experience designing, building and testing advanced air vehicles, both manned and unmanned systems. Patrick has worked almost exclusively in small, agile companies – exemplified by Burt Rutan’s Scaled Composites and Paul MacCready’s AeroVironment -- that have a reputation for rapid, inexpensive development of groundbreaking systems. During Patrick’s years at Scaled as a Project Engineer, the company flew a completely new aircraft design every nine months. Later at AeroVironment, he became a key member of the Pathfinder / Helios solar-powered UAV team. His mission plan for Helios resulted in a maximum altitude of 97,863 feet, a record that beat the SR-71 by 12,000 feet. He then became Project Manager for the Pathfinder flight test team. In 2002, he led the team through a flight test series that demonstrated 3G-cell phone and digital TV broadcast from the Pathfinder flying at 65,000 24 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel feet. He spent three years developing an internal combustion engine powered by hydrogen. This hydrogen engine was demonstrated by running in a test cell for eight days of continuous around-the-clock operation. The engine is now used as the power plant for the AeroVironment Global Observer long endurance unmanned aircraft system. Next, he worked as Program Manager for the Red Bull Stratos high-altitude parachute jump, leading the team through system design and fabrication to capsule pressurized testing and parachute systems tests. His broad experience in dozens of manned and robotic vehicle systems underlies his knowledge of project management and team leadership to quickly integrate and test new vehicles with a finely tuned balance of cost, schedule, and risk. Michael Matarrese, Ph.D. - Lead Airfoil Analysis Engineer Education Ph.D., MS, Aerospace Engineering, University of Michigan, (Specialization: Gas Dynamics.) BS (Summa cum Laude), Aeronautical and Astronautical Engineering, Ohio State University. Mike has twenty years experience in aerospace engineering, including four years working for Burt Rutan at Scaled Composites LLC., and recently eight years as independent consultant. Mike has experience in solar energy research and development, including work as founder and chief technical officer for a solar energy Start-up Company. His expertise includes: gas dynamics and heat transfer, computational fluid dynamics, aircraft design, numerical analysis, system modeling and optimization, analytical methods, and software development. Mike has provided engineering services for Scaled Composites, AeroVironment, Analytical Methods, Pyramid Space, NASA, Yellow Roadway, and others. A partial list of Mike’s experience and accomplishments include: Sierra Nevada Corporation, Centennial, CO: principal aerospace engineer, aerodynamics analysis group. NASA, Ames Research Center: modeling of airframe aerodynamics and performance. BridgeTech Industries, LLC, Boulder, CO: Chief Technical Officer and Founder. Scaled Composites, LLC, Mojave, CA: Worked closely with Burt Rutan to design and analyze several new aircraft, including Vjet and Proteus. Aerovironment, Inc., Simi Valley, CA: performed computational fluid dynamics analysis and design optimization of various unmanned aircraft. Brandon Arroyo –Lead Electrical/Software Engineering Manager President/CEO of i7 Engineering, Inc. Brandon is an engineering entrepreneur who has a passion for the uses of technology for the advancement of our lives. His engineering firm i7 Engineering, Inc. specializes in the development of advanced electrical, mechanical, software and autonomous robotic systems, primarily for the aerospace and defense industries. In 2010, prior to i7's formation, Brandon and other i7 engineers were contracted to design and construct electrical systems for the Red Bull Stratos project. Their engineers developed the remote control, solid-state, space-rated electrical systems, which successfully provided power and control for life-support, cameras, telemetry and many other vital systems. The project was designed to transport skydiver Felix Baumgartner to the edge of space, to be the first skydiver to break the sound barrier while in free-fall, which he accomplished October 14, 2012 falling at over 834mph from 128,100ft. i7 Engineering is now developing a spacecraft for Team Stellar, one of 24 teams competing for the Google Lunar X Prize, which plans to send a robotic spacecraft to the Moon. The Google Lunar X prize is an international moon exploration challenge organized by the X Prize Foundation, and sponsored by Google, to land a robotic craft on the lunar surface, to travel at least 1,650 feet (500 meters) and send data and high definition images back to Earth. The first privately funded team to do this by Dec. 31, 2015, will receive the $20 million grand prize. 25 Ocean Aero Inc. Proprietary Data Submaran – An Autonomous Unmanned Marine Vessel Steve Arroyo – Lead Electrical Hardware Engineer Senior Electrical Engineer for i7 Engineering, Inc. Education BSEE, Electrical and Electronics Engineering California Polytechnic University Steve is a native Californian who has a passion for designing complex systems. He is a Senior Electrical Engineer for i7 Engineering, Inc. specializing in the development of advanced electrical, mechanical, software and autonomous robotic systems, primarily for the aerospace and defense industries. In 2010, prior to i7's formation, Steve and other i7 engineers were contracted to design and construct electrical systems for the Red Bull Stratos Project. Their engineers developed the remote control, solid-state, space-rated electrical systems, which successfully provided power and control for life-support, cameras, telemetry and many other vital systems. The project was designed to transport skydiver Felix Baumgartner to the edge of space, to be the first skydiver to break the sound barrier while in free-fall, which he accomplished October 14, 2012 falling at over 834mph from 128,100ft. i7 Engineering is now developing a spacecraft for Team Stellar, one of 24 teams competing for the Google Lunar X Prize which plans to send a robotic spacecraft to the Moon. The Google Lunar X prize is an international moon exploration challenge organized by the X Prize Foundation, and sponsored by Google, to land a robotic craft on the lunar surface, to travel at least 1,650 feet (500 meters) and send data and high definition images back to Earth. The first privately funded team to do this by Dec. 31, 2015, will receive the $20 million grand prize. Chris Todter - Engineer: Electrical and Marine Sensors Education BSEE, Electrical Engineering University of Michigan 1972 Chris is most recently a Consultant to Earthship Deep Challenge, James Cameron’s expedition to the bottom of the ocean. This involved developing inertial measurement instrumentation, performing flight dynamics scale model testing and designing stabilization aerodynamic fins for the final vehicle. Prior to that he was the Senior Scientist for MshipCo, developing new sensors, and measurement systems for Navy Contract, including hydrodynamic analysis of innovative planeing hulls and the testing, R&D and development of a new high speed Naval surface effect craft. Chris also has significant ocean racing design experience work with BMW Oracle Racing, multihull challenge for the America’s Cup. Holding the position of Manager of the Instrumentation, Analysis and Performance Optimization Department. This role included aerodynamic design of their Wing Sail, Meteorological modeling, as well as developing several advanced sensors. Prior to this he was Technical Director for Oracle Racing, challenger for the America’s Cup. This role involved both technical management and design team coordination, as well as specific contributions of design and analysis in all areas of under water aerodynamics, hull design, mast and sail aerodynamics, and several projects involving advanced technology and innovation. Chris also has established business that develops and manufactures innovative miniaturized electronic wireless sensors including compasses, load-cells, anemometry, pressure, motions, and dynamometry. Co-developed an advanced Computational Fluid Dynamics flow simulation and visualization program for aero and hydrodynamic use. Complete resumes for the entire team are available upon request. 26 Ocean Aero Inc. Proprietary Data