Chapter 2: Management of community supplies

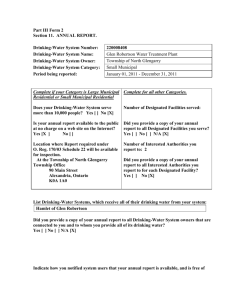

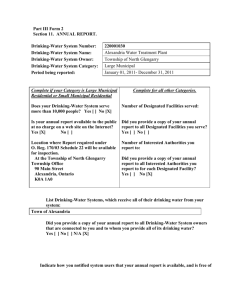

advertisement