Supplementary Information (docx 1145K)

advertisement

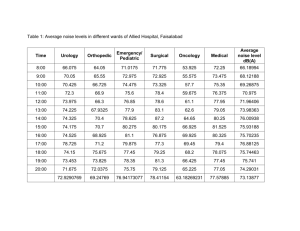

Supporting Information Colored ultrathin hybrid photovoltaics with high quantum efficiency Kyu-Tae Lee†, Jae Yong Lee†, Sungyong Seo, and L. Jay Guo † These authors contributed equally to this work. Department of Electrical Engineering and Computer Science, The University of Michigan, Ann Arbor, Michigan 48109, USA Figure S1. a) AFM images of Ag films on Ge, PTCBI, and Si substrates, b) refractive indices of PTCBI and a-Ge, c) Absorption spectrum of wetting layers, d) Calculated transmission spectrum of 10 nm Ag layer on wetting layers. In terms of optical performance, the rough surface morphology can induce the scattering that leads to broad transmission or reflection spectrum, which is typically not a desirable property. Moreover, it is observed that the sheet resistance of the non-flat metal surface is high, yielding the poor electrical conductivity of the electrode. In this regard, it is important to study a surface morphology of the thin Ag film as ~20 nm of Ag layer in anode is employed in our design. It is well-known that the thin Ag film deposited on the germanium (Ge) shows little surface roughness, small grain-size distribution, and low sheet resistance, which is attributed to the fact that the Ge wetting layer can reduce the mass transportation and surface diffusion of Ag. Due to the transparency of the Ge material in infrared (IR) regions (> 2 µm), there was no issue when depositing the thin Ag film on Ge wetting layer. However, the Ge has a very significant absorption in the visible ranges owing to the presence of the bandgap of Ge (0.66 eV) in the near IR. Considering that even 1 nm of Ge can generate a large loss, there is a critical need to find a material that can make the surface of thin Ag film smooth with an insignificant absorption. We performed AFM measurements on the deposited thin Ag film on PTCBI, Ge, and silicon substrates. It is found that the optically thin Ag film on PTCBI layer can be fairly even that is comparable to what the Ge provides as described in Figure S1a. The average root-mean-square (RMS) value of 10 nm Ag on the silicon substrate is 8.40 nm as a reference. On the other hand, the RMS values of surface roughness of 10 nm Ag on 2 nm Ge and 2 nm PTCBI are 0.235 nm and 0.213 nm, respectively. This lower RMS value implies that the scattering loss is significantly reduced. Another important feature of the PTCBI wetting material is much lower absorption than the absorption of Ge layer. In Equation S1, it is obvious that the light absorption is proportional to the real (n) and imaginary parts (k) of refractive index of material. This means that a material with higher values of complex refractive index will suffer from the large absorption loss. The n and k values of PTCBI and Ge were measured by an ellipsometer and demonstrated in Figure S1b. It is evident that the n and k values of Ge material are much higher than those of PTCBI, suggesting the large light absorption of Ge. In Figure S1c, the calculated absorption spectra in 5 nm PTCBI and Ge are illustrated showing that the absorption of PTCBI is ~3 % whereas the absorption of Ge is ~55 % at 425 nm. Additionally, the transmission of 10 nm Ag on 5 nm PTCBI and 5 nm Ge on glass substrates is simulated as exhibited in Figure S1d. At 400 nm, the transmission in the case of Ge is only ~36 %, while the transmission of PTCBI case is ~81 %. As is observed in the figure, generally there is a negligible difference between 10 nm Ag films on PTCBI and glass substrates. From these characteristics (1. low surface roughness 2. trivial absorption loss), it turns out that the PTCBI can be a great alternative to the Ge as a wetting layer in the visible ranges. Light Absorption 2c 0 kn E ( x, ) 2 (1) Figure S2. Calculated (a-c) and measured (d-f) angular dependences for s-polarization. We studied an angle dependence of our colored PVs for s-polarization shown in Figure S2. 27, 18, and 10 nm of a-Si layers are used to create cyan, magenta, and yellow (CMY) colors. Angle resolved reflection spectra were simulated (Figure S2a-c) by using a transfer matrix method and measured (Figure S2d-f) by a variable angle spectroscopic ellipsometer (VASE, J. A. Woollam) for angles of incidence ranging from 15° to 60°. The simulation results show a good agreement with the experiment data. It is clear to see that a resonance remains at the same level over large incident angles. This angle insensitive property is due to the trivial phase shifts accumulated during the propagation compared to the reflection phase shifts at the interface between a-Si and metal. Table S1. Summary of power conversion efficiency of each colored cell. Cyan device Magenta device Yellow device Efficiency (%) 1.92 2.80 2.36 Jsc (mA cm-2) 4.89 6.79 6.50 Voc (V) 0.62 0.65 0.60 FF (%) 63 64 61 The performance of devices is characterized by current density-voltage (J-V) measurement. Circular-shaped devices with a 1 mm diameter are tested under illumination by AM1.5 simulated sunlight (100 mW cm-2). The intensity of the light is uniformly distributed throughout the cell area by an optical setup. A Keithley 2400 is used for the data acquisition of current and voltage values in J-V. Short circuit current density (Jsc), open circuit voltage (Voc), and fill factor (FF) are determined using the J-V data. The above three power conversion efficiency (PCE) determining values are the average of nine devices per a substrate. All the devices showed Voc and FF values, larger than 0.6 V and 60 %, respectively. Figure S3. Calculated absorption spectra in a-Si layer depending on the Ag layer thickness of the DMD anode for yellow, magenta, and cyan. The top metal layer thickness is related to Q-factor of the optical resonance and will affect the amount of light absorbed by the a-Si layer. Figure S3 shows the influence of the thickness of Ag film on the absorption in a-Si layer, which is directly related to the photocurrent Jsc. As can be seen in those spectra, the resonance gets sharp as the Ag thickness increases because of the increased reflectance of the DMD layer in the FabryPerot cavity. This results in lower power conversion efficiency (PCE) since the absorption in a-Si layer is reduced. Since light cannot transmit through the solar structure and most of incident light is absorbed by the photoactive layer, the complementary spectrum of the absorption in a-Si is essentially the reflection profile of the structure. Even though increasing the Ag thickness decreases the PCE, a resonance behavior becomes more pronounced, yielding a narrow bandwidth (i.e. high color purity). In this work to clearly demonstrate the photon recycling scheme, in our device design we focused on attaining a sharp resonance so we used 23 nm of Ag film by sacrificing the power conversion efficiency to some extent. We calculated photocurrent Jsc for different Ag film thicknesses and the results are summarized in the Table S2. As expected the power conversion efficiency can be improved by simply reducing the thickness of Ag layer (e.g. Ag=10 nm). Thinner and continuous Ag can be obtained, e.g. by using our recent finding that adding small amount of Al during Ag deposition can produce an ultrathin (~7 nm), smooth and low loss film. Table S2. Summary of calculated Jsc values as a function of the Ag layer thickness in DMD anode with 20 nm WO3 for CMY-colored devices. WO3=20 nm Ag thickness (nm) Jsc (mA cm-2) Cyan Magenta Yellow 10 5.78 8.40 8.66 15 5.54 8.09 7.85 20 5.30 7.59 7.17 23 4.97 6.92 6.68