File - Anne Blanchard`s E

advertisement

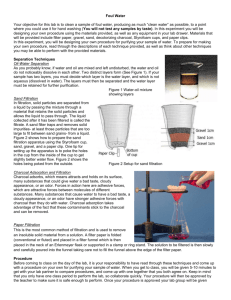

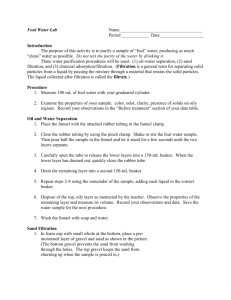

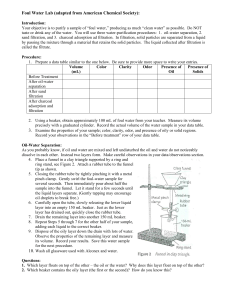

Anne Blanchard & Amelia Ingraham Chemistry period G Foul Water Lab If three water-purification procedures are used on the “foul water” than, the “foul water” will be stripped of the solid materials and be as clean as possible. The objective of this lab is to purify water by using three steps: 1. Oil-water Separation 2. Sand Filtration 3. Charcoal Absorption In the first of separating oil and water, the objective is to get rid of the oil because oil and water do not dissolve in each other. In the second step of sand filtration, the sand filter traps and removes solid impurities from the “foul water”. In the last step of the water-purification process, the filtration is when solid particles are separated from a liquid by passing the mixture through a material that retains the solid particles and the charcoal absorbs the substances that give the water bad taste, odor, and/or a cloudy appearance. The independent variables in this lab are the three different methods of water-purification: oil-water separation, sand filtration, and charcoal absorption. The dependent variable is the total amount of purified water at the end of the lab. Cleaning “foul water” is a procedure that requires three or more steps. The amount of clean water at the end of the lab is the dependent variable because the three steps of waterpurification cause a loss of water and the amount depends on how much water is lost in each one of the steps. The amount of water is dependent because it is a measure of the independent variable. The independent variables are the three steps because they can change. The steps can change by the amount of sand and charcoal you use and the amount of oil there is to remove. Procedure: 1. In your laboratory notebook, prepare a data table similar to the one shown here. Be sure to provide more space to write your entries. 2. Using a beaker, obtain approximately 100 mL of foul water from your teacher. Measure its volume precisely with a graduated cylinder. Record the actual volume of the water sample in your data table. 3. Examine the properties of your sample: color, clarity, odor, and the presence of oily or solid regions. Record your observations in the “Before treatment” row of your data table. Oil-Water Separation: 4. Place a funnel in a clay triangle supported by a ring and ring stand. Attach a rubber tube to the funnel tip. 5. Close the rubber tube by tightly pinching it with your fingers (or by using a metal pinch clamp). Gently swirl the foul-water sample for several seconds. Then immediately pour about half the sample into the funnel. Let it stand for a few seconds until the liquid layers separate. (Gentle tapping may encourage oil droplets to break free.) 6. Carefully open the tube, slowly releasing the lower liquid layer into an empty 150-mL beaker. Just as the lower layer has drained out, quickly close the rubber tube. 7. Drain the remaining layer into another 15—mL beaker. 8. Repeat steps 5 through 7 for the other half of your sample, adding each liquid the correct beaker. Which beaker contains the oily layer? How do you know? 9. Dispose of the oily layer as instructed by your teacher. Observe the properties of the remaining layer and measure its volume. Record your results. Save this water sample for the next procedure. 10. Wash the funnel with soap and water. Sand Filtration 11. Using a straightened paper clip, poke small holes in the bottom of a disposable cup. 12. Add pre-moistened gravel and sand layers to the cup. (The bottom layer of gravel prevents the sand from washing through the holes. The top layer of gravel keeps the sand from churning up when the water sample is poured into the cup.) 13. Gently pour the sample to be filtered into the cup. Catch the filtrate (filtered water) in a beaker as it drains through. 14. Dispose of the used sand and gravel according to your teacher’s instructions. Do not pour any sand or gravel into the sink! 15. Observe the properties of the filtered water sample and measure its volume. Record your results. Save the filtered water sample for the next procedure. Charcoal Adsorption and Filtration 16. Fold a piece of filter paper two times, then separate it with three layers on one side and one layer on the other. 17. Place the folded filter paper in a funnel. Hold the filter paper in position and wet it slightly so that it rests firmly against the base and sides of the funnel cone. 18. Place the funnel in a clay triangle supported by a ring. Lower the ring so that the funnel stem extends 2 to 3 cm inside a 150-mL beaker. 19. Place one teaspoon of charcoal in a 125- or 250-mL Erlenmeyer flask. 20. Pour the water sample into the flask. Swirl the flask vigorously for several seconds. Then gently pour the liquid through the filter paper. Keep the liquid level below the top of the filter paper—liquid should not flow through the space between the filter paper and the funnel. 21. If the filtrate is darkened by small charcoal particles, refilter the liquid through a clean piece of moistened filter paper. 22. When you are satisfied with the appearance and odor of your charcoal-filtered water sample, pour it into a graduated cylinder. Record the final volume and properties of the purified sample. 23. Follow your teacher’s suggestions about saving your purified sample. Place used charcoal in the container provided by your teacher. 24. Wash your hands thoroughly before leaving the laboratory. You should put on protective goggles and continue to wear them until the lab is completely finished. The lab apron should be worn also to ensure the safety of yourself and others. Data Table: Volume Color Clarity Odor (mL) Before 100 treatment Presence of Presence of oil solids Brown, Cannot see Rotten About 1 Chunky, Rusty, through the Chinese mm, brown/white, yellow sample food, visible throughout peanut oil whole sample After oil- 75 Brown, Not clear, Rotten Less than Chunky, water Rusty, but more Chinese before, brown/white, separation Yellow visible food most throughout removed whole sample After sand 75 filtration After Visible, but Rotten Very little Only at the not dark no exactly Chinese amount, bottom of clear food most the sample, removed chunky Small No solids at all Absolutely Can see charcoal clear and right layer, adsorption/ visible through the barely sample visible filtration 56 Brown, but No odor Collected volumes of water for each lab were the following measurements in mL: 56, 50, 75, 40, 72, 52, 71, 50, 90, 70, 60, and 35. Percent of water purified = Volume of water purified X100% Volume of foul-water sample Percent of water purified = 56 mL X 100% = 56% 100 mL The volume lost during purification is 44 mL. The percent of the original foul-water sample was 44% during the purification process. The largest percent recovery obtained by a laboratory is 35%. The smallest percent recovered is 90%. The range of percent recovery of data in my class was 35-90%. The average percent of recovery in my class was 60.083%. The median of percent recovery data is 56%. In conclusion, the three steps of purifying the water worked in order to purify the foulwater, but it was not drinkable. The oil-water separation, sand filtration, and charcoal absorption and filtration cleaned the water of its imperfections. The data stated that the water was clean, but not drinkable. The water was not drinkable because there was salt in the water which can only be removed from distillation. Our water could be used for daily uses such as washing your hands. The reliability of data seemed to be true because everyone in the class had a volume of water that was similar to everyone else’s. Some improvements that could be made to this lab is in the oilseparation step, how to decipher when the oil layer is gone. The “purified water” sample was not “pure” water because when we used a tool to tell us if the water was drinkable, the light lit up which means there was still some imperfect part in the water which was the salt. The relative success of each laboratory group can be judged by lining the samples from clearest to least clear to find out which seem the most clear and then to insert the tool in that tells which water is the purest and which is the least pure. To improve the water-purification procedure so that a higher percent of purified water could be recovered could be to make sure each laboratory user is sure on when to stop the clap and to stop the water from flowing out when it is supposed to be only separating the oil. The total time it took to purify the water was about an hour and a half. The time invested did not result in a large enough sample of sufficient purified water because the percent of water lost in the process was 44%. The extra investement of time would not “pay off” because the amount of time it takes is not breaking even with the amount of pure water that comes out of at the end results. Ten times as much time would still be a waste of time because the water being produced would stay the same, for each time the lab is preformed. Municipal water-treatement plants do not use distillation to purify their water because they distillation process is a lot longer than the three-step water-purification process, and when they use the distillation process it costs more money because in order to purchase a distiller for the amount of water needed to provide would be insufficient.