Fall Protection Requirements for Residential Construction

advertisement

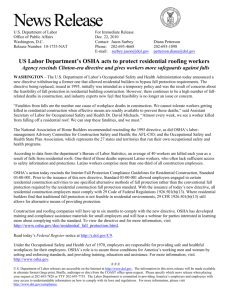

FALL PROTECTION REQUIREMENTS FOR RESIDENTIAL CONSTRUCTION A. Introduction Residential construction involves the building of a dwelling unit, such as a residence. The typical design is wood frame, but may also contain block exterior walls or cold metal formed studs and an extremely limited of structural steel to hold the primary wood frame together. Nearly 50 workers are injured every minute of the 40 hour work week and almost 17 employees die each day. Falls in residential construction is a significant source of workplace fatalities in the US. Falls are the number one source of construction fatalities. Many fall hazards could be eliminated through planning of the project. The employer should do a hazard analysis and determine the best control measures to prevent falls on the residential construction site. Physical hazard controls (e.g.: harness and lanyard with anchorage points, nets, or standard railing are considered to be the primary method to control falls on the sites. Other methods, such as a fall protection plan are administrative controls and are not considered to be effective. The employer has the burden of proof to demonstrate that conventional fall protection can’t be used. B. Compliance Activity OSHA has recently rescinded the Interim Fall Protection Compliance Guidelines for Residential Construction. OSHA now believes that conventional fall protection is readily available and can be used for residential construction activities. Employers must abide to the 29 CFR 1926.501(b)(13) standard that requires the use of fall protection in residential construction. C. Control Measures Residential construction employers generally must ensure that employees working six feet or more above lower levels use control measures that are appropriate to protect workers. There are three primary methods that may be used to prevent falls on a residential construction site. The methods consist of: 1. Harness, lanyard, and deceleration device (self retractable in some cases) attached to a substantial anchorage point that support 5,000 pounds per employee or designed under the supervision of a qualified person with a safety factor of two. We also have to meet the inspection and design requirements for the harness and lanyard. All fall protection equipment must be inspected before each of use. Any damaged equipment needs to be taken out of service. As an alternative, you may also use a restraint system. Restraint systems are better because we do not allow for a fall to occur. In many cases, it may be difficult to find a point on the building that is strong enough to meet the requirements for anchorage points. There are products on the market that may be used as an anchorage. The picture illustrates an example of a type of anchorage system “safety pole” that may be used on a residential construction project. 2. Safety nets that meet the design and installation criteria. The net has to be drop tested and clear of debris. Rigging must also be done properly to ensure workers do not bounce out of the net, fall too far, or contact objects’ The picture illustrates a safety net that has been installed to prevent falls to the interior of the building. To use the system you should consult with the manufacturer’s specifications and an engineer to ensure the walls have properly braced. 3. Properly designed and installed guardrail systems that incorporate posts, a mid rail and a top rail. The top rail must be capable of supporting a force of 200 pounds applied in any direction. The picture illustrates a guardrail system that is installed on the second floor. Guardrails must meet the design criteria and have adequate strength to support 200 pounds for the top rail and 150 for the mid rail. The structure must be free of sharp edges. There are also other work methods that may be used to reach the work, such as scaffolds, ladders, and edges. aerial lifts. The equipment must be set up and used properly to prevent falls. OSHA allows for the use of warning lines and safety monitors on low slope roofs. D. Fall Prevention Plan As a last alternative, the employer may use a fall prevention plan, if they can prove that conventional fall protection is not feasible. Fall prevention plans are an administrative control and do not provide for full employee protection. Falls may still occur despite developing and implementing fall prevention plan. If a fall protection plan is used, the contractor must make the information as specific as possible to protect and discuss why conventional fall protection can’t be used. OSHA believes fall protection is readily available for most applications in residential construction. Resources The following resources are available on the internet: Colleges or Universities 1. Georgia Tech: http://www.oshainfo@gatech.edu 2. Georgia Tech Research Institute: http://www.gtri.gatech.edu/lab/shet 3. University of Alabama: http://alabamasafestate.ua.edu Organizations 1. Construction Safety Council: http://www.buildsafe.org 2. American Society of Safety Engineers: http://www.asse.org 3. National safety Management Society, http://wwwnsms.org Government 1. NIOSH: http://www.cdc.gov/niosh/elcosh 2. OSHA: http://www.osha.gov 3. OSHA Training and Education Center, http://www.osha.gov/dcsp/ote Miscellaneous 1. Construction Site Injuries: http://www.construction-injuries.com 2. Safety Information: http://www.safetyinfo.com 3. National Association of Home Builders, http://www.nahb.org/page.aspx/category/sectionID=204 4. Occupational Safety and Health Administration, Residential Construction Assistance Page, http://www.osha.gov/SLTC/residential/index.html 5. Electronic Library of Occupational safety and Health, http://research.elcosh.org/ 6. Laborers Safety and Health Fund of North America, http://www.lhsfna.org/index.cfm?objectID=96825F9E-D56F-E6FA-9772DD3D79FEF62F 7. Washing State Department of Labor and Industries, Fall Protection Video, http://www.lni.wa.gov/Safety/TrainTools/Videos/Online/Roofing/default.asp