15-Chapter_SS_(teaching_materials)

advertisement

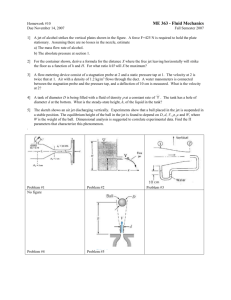

Chapter SS: Examples of safety strategies and engineering solutions Compiled by Prof Vladimir Molkov (University of Ulster) from the free eBook “Fundamentals of hydrogen safety engineering” (www.bookboon.com) 1 © HyFacts 2012/13 – CONFIDENTIAL – not for public use 1 About chapter content In this chapter safety strategies and engineering solutions for the following seven examples will be considered: 1. Inherently safer design of fuel cell (FC) systems (coupling of technological and safety requirements) 2. Separation distances from unignited leak and jet fire from the same source: which separation distance is longer? 3. Strategy for safer use of forklift in warehouse (calculation of PRD diameter by the similarity law for unignited releases to exclude cloud formation) 4. Effect of restrictor in a pipeline (the dimensional flame length correlation) 5. Momentum-dominated and buoyancy-controlled leaks: decrease of separation distances for hydrogen transport pipelines 6. Plane jets and reduction of separation by innovative PRD (Pressure Relief Devices) 7. Increase of fire resistance of onboard storage Materials in this chapter are based on materials of previous chapters knowledge of which is assumed. 2 Inherently safer design of FC systems Let us consider a 50 kW FC system, e.g. suitable for multi-family dwellings, and a 150 kW FC for a vehicle. Assuming that electrical efficiency of FC is 45%, and that the heat of reaction is 132.5 kJ/g, the mass flow rate for functioning of FC can be calculated as (50 kW)/0.45/(132.5 kJ/g)=0.84 g/s for 50 kW FC, and 2.52 g/s for 150 kW FC. For example, the mass flow rate 0.84 g/s can be provided at pressure drop P=5 bar and diameter of orifice D=1.8 mm (or pressure drop P=2 bar, and diameter of orifice D=2.9 mm). Unfortunately, current FC systems are often designed that piping diameter is quite large up to D=15 mm (or even 25 mm!?) and pressure as large as P=15 bar. The mass flow rate for orifice diameter D=15 mm, and pressure P=15 bar is 170 g/s. This is significantly above the required mass flow rate for considered systems (below 3 g/s). In a case of incident the amount of hydrogen and level of turbulence in a cloud created during a release of flammable hydrogen-air mixture could be unacceptable from a point of view of the release consequences. The design of FC that requires such high pressure, e.g. for water management, has to be changed. There are examples of FC working at very low pressure drops or even hydrogen intake by negative overpressure. Coupling of technological and safety requirements would significantly improve level of public safety and competitiveness of FC system. In particular, separation distances could be reduced essentially. For example, jet flame length is proportional to mass flow rate as (m)1/3. Matching technology and safety requirements would decrease flame length in these particular cases by (170/0.84)1/3=6 times or by (170/2.52)1/3=4 times respectively. 3 Separation distances for unignited leak and jet fire While the probability of ignition of unscheduled release is unknown and can be debated for another decade(s), there is a need to know which separation distance is longer – for unignited release or jet fire from the same leak source. Let us briefly overview an issue about prescriptive and performance-based approaches to regulations, codes, and standards (RCS). The interrelationships 2 © HyFacts 2012/13 – CONFIDENTIAL – not for public use between prescriptive and performance-based approaches are well established for fire safety engineering and are now under discussion for hydrogen safety engineering. Usefulness of prescriptive codes for determination of separation distances, e.g. International Fire Code (edition 2006) is questionable. For example, IFC provides separation distance from non-reacting leaks in tables without any reference to the original source of information or reasoning of how those distances were chosen. It has been shown that separation distance depends on storage pressure and leak diameter. Tables with prescriptive separation distances without information about pressure and leak diameter are ill-posed and could lead to serious accidents. Such kind of “black box” RCS should be banned for safe introduction of HFC systems and infrastructure and provision of public safety. 3.1 Separation from unignited leak An unignited jet deterministic separation distance is the distance where hydrogen concentration decays to 4% by volume, e.g. to exclude penetration of flammable hydrogen-air mixture into a buildings through air intake systems. The similarity law gives the distance to 4% in a momentum-dominated jet. This is a conservative estimate of the separation distance as buoyancy-controlled jets decay faster compared to momentum-dominated jets. x4% 1574 N D , (SS1) where N is the density in the actual nozzle, kg/m3; and D is the leak diameter, m. Equation (SS1) shows that the unignited jet separation distance is clearly a function of a leak diameter D (directly proportional) and hydrogen density in the leak exit N (directly proportional to storage pressure with correction on non-ideal behaviour of hydrogen at high pressure above 10 MPa). 3.2 Jet fire length The dimensionless jet flame length, LF/D, is a function of storage pressure. Figure SS1 shows that jet flame tip is located where an unignited jet from the same source would decay to 8%-16% of hydrogen by volume (best fit is at 11% by volume). Figure SS1. The correlation between the dimensionless flame length, LF/D, (points) and the dimensionless distance to a particular concentration in a non-reacting jet, x/D, (curves for 8%, 11%, 16% by volume) from the same leak source for different storage pressures (Molkov, 2012). 3 © HyFacts 2012/13 – CONFIDENTIAL – not for public use It is worth to remind the conclusion from chapter F: flame tip distance from the leak source is longer than the distance to the axial concentration of 29.5% by volume in unignited jet (stoichiometric hydrogen-air mixture) as was stated earlier by some researchers; the underestimation of flame length is from 2.2 times (16%) to 4.7 times (8%). 3.3 Separation distances for jet fire Three widely accepted criteria of harm to humans by temperature are (Molkov, 2012): 70oC – “no harm” limit; 115oC – pain limit for 5 min exposure; 309oC – third degree burns for a 20 s (“death” limit). These three temperatures are presented by horizontal lines in Figure SS2. Intersections of these three lines with axial temperature curve gives three separation distances (Molkov, 2012): x=3.5LF – no harm separation distance (70oC); x=3LF – pain limit separation distance (115oC, 5 min); x=2LF – “death separation distance (309oC, 20 s). Figure SS2. Axis temperature as a function of flame calibre (Molkov, 2012). 3.4 Which separation from a leak is longer: for unignited jet or jet fire? The ratio of distances to 8% of hydrogen by volume (conservative estimate of the flame length) to 4% (the lower flammability limit = LFL) can be calculated from the similarity law (Molkov, 2012) Cax D , 5.4 N CN S x (SS2) where Cax is the mass fraction of gas at axial distance x from the nozzle, CN is the mass fraction of gas in the nozzle (CN=1 for pure gas release), x is the axial distance from the nozzle, and N is the density of hydrogen in the nozzle exit. For the same storage pressure, i.e. the same density in the nozzle N, and the same leak diameter, D, the ratio of distances to 8% and 4% can be expressed as inverse ratio of corresponding mass fractions 4 © HyFacts 2012/13 – CONFIDENTIAL – not for public use x8% C4% . x4% C8% (SS3) Mass fractions of hydrogen in air corresponding 8% by volume and 4% by volume are 0.00599 and 0.00288 respectively (Molkov, 2012). Thus, the ratio is equal x8%/x4%=LF/x4%=288/599=0.48. From previous section we know that three ratios of separation distance to jet flame length are: death limit - x/LF=2; pain limit - x/LF=3; no harm limit - x/LF=3.5. Thus, ratios of a separation distance from jet fire to a separation distance to LFL in an unignited jet from the same leak source are: Death limit (309C, 20 s): xT=309C(8%)/x4%=0.48*2=0.96; Pain limit (115C, 5 min): xT=115C(8%)/x4%=0.48*3=1.44; No harm distance (70C): xT=70C(8%)/x4%=0.48*3.5=1.68; “Unexpected” conclusion: all three separation distances for jet fire are equal or longer compared to the separation distance to LFL (non-reacting release). This conclusion could underpin cost-effective hydrogen safety engineering design of hydrogen systems and infrastructure. 4 A strategy for use of forklifts in warehouse Typical warehouse is a closed space and probably the worst-case scenario is a deflagration of flammable hydrogen-air cloud created during unscheduled hydrogen leak from a storage tank of a forklift or similar, e.g. through a pipeline to FC or through faulty pressure relief device (PRD). One possible safety strategy for this scenario is to exclude the formation of a flammable hydrogen-air mixture under the ceiling that during deflagration could destroy the structure. If this safety strategy could be realised then only a comparatively small volume of the warehouse will be occupied by flammable mixture and deflagrate (assessment of this deflagration overpressure effects should be done separately – not part of this example). Only part of the hydrogen jet within the flammability range would deflagrate. Let us calculate the PRD diameter that in case of unscheduled release, e.g. by PRD fault, would not create a flammable cloud under the ceiling at all: hydrogen concentration should decay to below of 4% by volume (LFL) before reaching the ceiling. Example scenario: upward (worst case in sense of flammable cloud formation) release from a forklift onboard storage at pressure of 35 MPa. The distance from PRD to warehouse ceiling is 10 m. To realize the suggested strategy the concentration on the jet axis at distance 10 m should be below 4% of hydrogen by volume (corresponding to 4% by volume mass fraction is Cax=0.00288). The similarity law Eq. (SS2) has to be applied. The under-expanded jet theory gives N=14.6 kg/m3 for storage pressure 35 MPa (simplified calculation based on the multiplication of the hydrogen density at atmospheric conditions, 0.084 kg/m 3, and the ratio of half of storage pressure to the atmospheric pressure, 350/2/1, would give an estimate: 350/2*0.084=14.7 kg/m3). Thus, the PRD diameter can be calculated from the similarity law straight forward as 1.5 mm D Cax 5.4 S 0.00288 1.204 x 10 0.0015 m . N 5.4 14.6 5 © HyFacts 2012/13 – CONFIDENTIAL – not for public use (SS4) 5 Effect of restrictor and pipeline diameter on separation distance A restrictor is often used on the exit from high pressure storage to a pipeline leading to a fuel cell. By definition the restrictor orifice diameter is smaller than internal diameter of the pipeline. Unfortunately, there are examples of hydrogen systems in which diameter of pipeline is unjustifiably large with serious consequences for potential incidents/accidents. For example, it is possible to find pipelines from high pressure storage to dispenser at hydrogen refuelling station (RS) with internal diameter of 25 mm (!). Let us consider an imaginary scenario in which 1 mm restrictor is placed in a pipeline from storage to dispenser at RS. Mass flow rate through 1 mm orifice at storage pressure 1000 bar is about 2.1 kg/min = 0.035 kg/s that is sufficient to fill in a car in a couple of minutes. The question to be answered: how the flame length would change if a designer would choose either 3 mm or 25 mm internal diameter of the pipeline? 5.1 Ignited release (under-expanded jet fires) The dimensional correlation for flame length is a convenient tool to be applied for this scenario with restrictor as it gives the flame length as a function of both pipe diameter and mass flow rate (Molkov, 2012). The dimensional equation for the flame length is LF 76 (m D) 0.347 , (SS5) where LF is the flame length, m; m is the mass flow rate, kg/s; and D is the diameter from which hydrogen escapes to surroundings, m. For a pipe of D=0.025 m diameter (with mass flow rate of m =0.035 kg/s, and restrictor diameter of d=1 mm) Eq. (SS5) gives flame length of LF=6.6 m (thus “no harm” separation distance is 6.6x3.5=23 m). For a pipe of D=0.003 m diameter (with mass flow rate of m =0.035 kg/s, and restrictor diameter of d=1 mm) Eq. (SS5) gives flame length of LF=3.2 m (thus “no harm” separation distance is 3.2x3.5=11.2 m). As we know the conservative separation distance estimated by the dimensional correlation is 50% longer. Thus, the conservative separation distances have to be 34.5 m and 16.8 m respectively. The conclusion from this analysis is that the pipe diameter affects the separation distance for ignited release (jet fire) even if the same restrictor is used. 5.2 Unignited release Let us consider unignited release for the same two scenarios: pipe diameter 25 mm and 3 mm (the same restrictor of 1 mm diameter). How the separation distance would change if the unignited release is through the full bore of broken pipeline? The similarity law Eq. (SS2) is applied for the assessment of separation distances in the two scenarios. Let us assume that a mass flow rate is defined by the restrictor only (flow losses can be neglected), and that the flow is choked in both cases, i.e. velocities at leak exit are sonic and equal (difference in reduction of temperature during expansion from 1 mm to 3 mm and 25 mm is neglected too as heat transfer from pipe walls would damp it to some extent). Thus, we can conclude from this analysis that the separation distance for unignited release in assumptions made does not depend on the pipe diameter (only on the restrictor diameter). This is not the case for the jet fire separation distances as follows from the previous section! It is worth noting that for the same conditions all three separation distances from jet fire are longer that separation distance from unignited leak (calculated by as a distance to hydrogen decay to 4% by volume on the jet axis). 6 © HyFacts 2012/13 – CONFIDENTIAL – not for public use 5.3 Momentum-controlled regime of expanded jet fire We have considered above high pressure under-expanded jet fires. Let us now estimate how flame length would change if our flow parameters are in the momentumcontrolled regime for expanded jets where the dimensionless flame length is the constant, LF/D=230 (see Figure SS3 with the dimensionless correlation for hydrogen flame length). The conclusion from this constancy is straight forward: for momentumcontrolled expanded jet fires the flame length, and thus the separation distances, grow proportionally to the leak diameter. Figure SS3. The dimensionless correlation for hydrogen jet flame length (Molkov, 2012). Red oval indicates momentum-dominated regime of jet fire with constant dimensionless flame length LF/D=230. 6 Separation distance and buoyancy Let us consider one example of how unignited separation distance can be decreased by buoyancy effect. Since 1938 the chemical industries in Hϋls (Ruhr area, Germany) exploits hydrogen pipeline of 215 km length with maximum pressure 2.5 MPa (25 bar) and maximum inner diameter of the pipe 27.3 cm. The under-expanded jet theory (Molkov, 2012) gives the diameter of the notional nozzle exit after the expansion of a jet equal to Deff=98 cm. The mass flow rate in case of full bore rupture of the pipe can be estimated from the under-expanded jet theory as 90 kg/s. By the way, such pipeline could serve a big city with population of 10 million people to provide supply of hydrogen to all cars. Indeed, in assumption that a car has to be refuelled once a week we need 10M fillings per week, i.e. about 1.4M cars per day. This is an equivalent of filling in of 3000 cars every 3 minutes (desirable time to fill in hydrogen-powered vehicle to satisfy customers’ expectation for refuelling time), or about 15 cars per second. If one fill is 6 kg then it is exactly the capacity of the pipeline. If the conservative approach to determination of separation distance is chosen and the jet without substantiation is accepted as momentum-dominated jet, then the similarity law would give a horizontal distance to 4% of hydrogen by volume as (N=1.267 kg/m3) 465 m (no attachment effect is included). This is hardly acceptable in practice and a realistic estimate of the separation distance should be carried out instead of the conservative estimate. Let us use the Schevyakov’s graph shown in Figure SS4 (Molkov, 2012) that gives a logarithm of dimensionless distance, x/D, to particular concentration of hydrogen (four curves shown in the graph are for 4%, 17%, 30%, and 60% respectively) as a function of the Froude number logarithm. Here D is either the actual leak diameter (expanded jets) or the notional (effective) nozzle diameter (under-expanded jets). 7 © HyFacts 2012/13 – CONFIDENTIAL – not for public use Figure SS4. Dimensionless distance, x/D, to particular concentrations of hydrogen on the jet axis as a function of the Froude number (Molkov, 2012). The logarithm of the Froude number for this imaginary release is Log(Fr=U2/gDeff)=5.2 (vertical red line in Figure SS4). If the Shevyakov’s graph (Figure SS4) is applied again in the assumption that the jet is in the momentum-controlled regime until the hydrogen concentration on the jet axis falls down to 4% by volume, then the separation distance would be 418 m. This can be calculated from the determined value of Log (x/D)=2.63 (see top horizontal red line in Figure SS4). This is quite close to the similarity law result of 465 m. However, the jet is momentum-dominated only down to concentration about 12% of hydrogen by volume (lower horizontal red line in Figure SS4). This is the concentration where vertical red line corresponding Log(Fr=U2/gDeff)=5.2 intersects Shevyakov’s curve denoted “downward jet”. The ordinate of the intersection is Log (x/D)=2.04 (see Figure SS4). Thus, the distance to location at which the jet will be deviated upward by buoyancy is 107 m. This is more than 4 times shorter compared to the separation distance calculated without accounting for effect of buoyancy! 7 Plane jets 7.1 Theoretical decay of concentration in round and infinite plane jets Theory predicts faster concentration decay in a round expanded jet compared to an infinite plane jet of the same size D (Chen and Rodi, 1984) Cax D 5.4 N round , CN S x Cax 2.13 N CN S D plane. x (SS6) For example, the plane jet of width D would decay at dimensionless distance (x/D)plane=100 to the same concentration as the round jet would decay at a distance that can be calculated from the following equality of concentrations, see Eqs. (SS6) 5.4 x 5.4 x 10 25.35 . D round 2.13 D plane 2.13 (SS7) i.e. at distance about four times longer compared to round jet. Can this theoretical conclusion about infinite plane jets be applicable to plane jets with finite aspect ratio (ratio of slot length to width)? This question will be answered later in this section. 8 © HyFacts 2012/13 – CONFIDENTIAL – not for public use 7.2 Decay of hydrogen concentration in finite aspect ratio plane jets 7.2.1 The switch-of-axis phenomenon The first difference between infinite and finite aspect ratio plane jets is the switch-ofaxis phenomenon (Makarov and Molkov, 2013). Figure SS5 demonstrates the switchof-axis phenomenon that can be briefly explained that the longest axis of the release from finite aspect ratio slot is perpendicular to the longest slot axis. Figure SS5. The switch-of-axis phenomenon (Makarov and Molkov, 2013). The switch-of-axis phenomenon provides a larger side area of the jet compared to round axisymmetric jet and thus increases the air entrainment. As the result of this a faster decay of hydrogen concentration in a finite aspect ratio plane jet compared to round jet of the same characteristic size can be expected (even if this is contrary to the theoretical result for infinite plane jet). This conclusion was confirmed experimentally (Mogi and Horiguchi, 2009) as follows from experimental snapshots in Figure SS6. Figure SS6 shows hydrogen flame for three different nozzles of the same cross-section area of 0.8 mm2 (storage pressure is 40 MPa). One of three nozzles was round nozzle of 1 mm diameter, and two other were plane nozzles with aspect ratio 5 (LxW=2x0.2 mm) and 12.8 (LxW=3.2x0.25 mm) respectively. Figure SS6. Hydrogen flame length for three different nozzles of the same cross section area: top - round nozzle of 1 mm diameter; middle - plane nozzles with aspect 9 © HyFacts 2012/13 – CONFIDENTIAL – not for public use ratio 5 (LxW=2x0.2 mm); bottom – plane jet with aspect ratio 12.8 (LxW=3.2x0.25 mm) (Mogi and Horiguchi, 2009). 7.2.2 Innovative pressure relief devices (PRD) with reduced flame length There is a clear need for development of innovative pressure relief devices with reduced flame length compared to “default” engineering solution of using round orifice in PRDs. Preliminary experiments carried out with PRD developed at the University of Ulster confirmed reduction of flame length from about 7.5 m to 1.8 m for the same mass flow rate at storage pressure in this tests of 350 bar. Innovative PRD should not have only reduced flame length yet to exclude initial fireball formation during PRD initiation. Example of engineering solution addressing this problem is shown in Figure SS7. The PRD has variable aperture with its smallest area during device initiation. More details can be found in the description of IP “Gas storage” of the University of Ulster (WO 2012/143740 A2, 26.10.2012). Figure SS7. PRD with variable aperture (IP WO 2012/143740 A2, 26.10.2012). Expected change of the flame length from current PRD and innovative PRD is depicted in Figure SS8 with respect to the flame from a PRD of hydrogen-powered vehicle presented in Chapter F. Figure SS8. Flame length from currently used PRD and innovative PRD. 10 © HyFacts 2012/13 – CONFIDENTIAL – not for public use 7.2.3 Storage tanks with increased fire resistance The reduction of flame length and decrease of mass flow rate from storage tank of fixed capacity can be achieved only by the increase of fire resistance of storage tanks. For type 4 onboard storage tanks fire resistance should be increased from current 3.56.5 minutes to 1-2 hours. One of potential technological solutions that could provide such drastic increase of fire resistance is shown in Figure SS9 (IP of the University of Ulster “Gas storage”, WO 2012/143740 A2, 26.10.2012). Figure SS9. Gas storage (IP WO 2012/143740 A2, 26.10.2012). Gas storage vessel comprises an internal tank that is at least partially surrounded by an external tank (that can be very lights as should not be pressure resistant) having a higher fire resistance than the internal tank (potentially type 4 tank for onboard storage of hydrogen), e.g. formed of incombustible material that excludes permeation, and a PRD. The internal tank is designed to store gas at a higher pressure that the external tank, and is made of comparatively lightweight materials through which hydrogen can permeate with comparatively low fire resistance. The external tank has means to control leaks from the internal tank (and inform about the need to change the tank if permeation or other leaks are above the limit established by the Commission Regulation (EU) No 406/2010 of 26 April 2010). The PRD may have a variable aperture, which is small in the beginning of the release and increases to the end of the blowdown, and which prevents high flame length and generation of destructive overpressure within an enclosure, such as a garage, at the start of the release. The gas storage vessel can provide safe onboard storage of compressed flammable gases, with enhanced fire resistance and reduced flame length from the PRD, especially for hydrogen-powered vehicles with the most high storage pressure compared to other gases. 8 References Chen, C and Rodi, W (1980) Vertical turbulent buoyant jets – a review of experimental data. Pergamon Press, Oxford. ISBN 0-08-024772-5. Commission Regulation (EU) No 406/2010 of 26 April 2010 implementing Regulation (EC) No 79/2009 of the European Parliament and of the Council on type-approval of hydrogen-powered motor vehicles. Official Journal of the European Union, vol. 53, 18 May 2010. [Accessed 01.04.12] http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:122:FULL:EN:PDF. 11 © HyFacts 2012/13 – CONFIDENTIAL – not for public use International fire code (2006). International Code Council. Makarov, D and Molkov, V (2013) Hydrogen plane jets. Intrenational Journal of Hydrogen Energy, (accepted for publication). Mogi, T and Horiguchi, S (2009) Experimental study on the hazards of high-pressure hydrogen jet diffusion flames. Journal of Loss Prevention in the Process Industries, vol. 22, pp. 45-51. Molkov V (2012) Fundamentals of hydrogen safety engineering, Part I and Part II, www.bookboon.com, free download eBook. 12 © HyFacts 2012/13 – CONFIDENTIAL – not for public use TABLE OF CONTENTS 1 ABOUT CHAPTER CONTENT 2 2 INHERENTLY SAFER DESIGN OF FC SYSTEMS 2 3 SEPARATION DISTANCES FOR UNIGNITED LEAK AND JET FIRE 2 3.1 Separation from unignited leak 3 3.2 Jet fire length 3 3.3 Separation distances for jet fire 4 3.4 Which separation from a leak is longer: for unignited jet or jet fire? 4 4 A STRATEGY FOR USE OF FORKLIFTS IN WAREHOUSE 5 5 EFFECT OF RESTRICTOR AND PIPELINE DIAMETER ON SEPARATION DISTANCE 6 5.1 Ignited release (under-expanded jet fires) 6 5.2 Unignited release 6 5.3 Momentum-controlled regime of expanded jet fire 7 6 SEPARATION DISTANCE AND BUOYANCY 7 7 PLANE JETS 8 7.1 Theoretical decay of concentration in round and infinite plane jets 8 7.2 Decay of hydrogen concentration in finite aspect ratio plane jets 7.2.1 The switch-of-axis phenomenon 7.2.2 Innovative pressure relief devices (PRD) with reduced flame length 7.2.3 Storage tanks with increased fire resistance 9 9 10 11 8 REFERENCES 13 © HyFacts 2012/13 – CONFIDENTIAL – not for public use 11