downloaded here.

advertisement

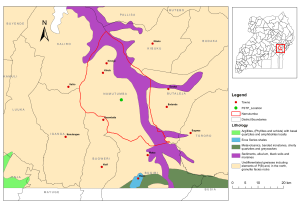

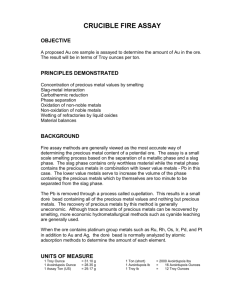

Research and development of technology of precious metals’ extraction from quartzite using a closed water cycle N. Tyushkova National Nano-Technological Research University (NITU), “Moscow Institute of Steel and Alloys” Moscow, Russia. email: cid_nofx@hotmail.com Abstract The results of process studies of ore showed that the most effective of the tested methods appeared to be the direct cyanidation of crushed ore up to 95 % cl. –0,08 mm. In this regard, the extraction of gold ranges from 91,7 % to 100 % , and silver – from 48 % to 68 % and with content of precious metals in dump cakes left the traces – 0,2 g/t on gold and 9,7-6,4 g/t on silver accordingly. A study of continuous process of countercurrent washing out of the tails of desalinization with sedimentation of gold and silver from the discharge of the 1-st densifier based on anion exchange resin АМ-2B allowed to make a conclusion being very important from the point of view of the environmental protection, about an opportunity of repeatable use of metal-free mixture in the course of desalinization and washing out of dissolved precious metals without reduction of the technological parameters. Introduction In the process of mining plants’ activity the huge amount of very small final tailings and ore slime are being accumulated. It happens as during treatment of many types of ores all extracted mined rock is being grinded up till the size of grains less than 0,1 mm and only then the ore components are taken from it with assay value from 1 to 50 % for different types of deposits. The remained 99-50 % of gangue are stored in as final tailings and slimes, occupying thus the big ground areas and demanding substantial expenses for the organization of the storage. Omissions and lacks of functioning of such pond tailings lead to an intensive drift of the crushed rock by water and wind and to environmental contamination. Experimental Work The subject of research appeared to be an ore sample represented with secondary quartzites having the industrial value. As for material composition, the quartzites sample being investigated refers to a type of gold-quartzy ore with small sulphide-content mineralization. The main industrially valuable component is gold (2,3 g/t) and pari passu silver (18,9 g/t). A certain value is represented by quartz as the raw material to produce silicate walling materials, because nonmetallic minerals by 85,4% are represented with San Luis Potosí, México 13-15 August, 2015 quartz with small content of barite. Clay minerals and sericite present with no more than 5,5% that opens an opportunity to wash out dissolved gold and silver as per a scheme of continuous countercurrent decantation. Results and Discussion The analysis of obtained data shows that the ionic content of cycle water circulation in crushing is almost no changed, excluding some accumulation of sulphates, iron, potassium and natrium. It has to be noted that the quartzites to be processed are characterized with relatively simple mineral content and as the obtained liquid phase as a result of contact of water with ore is slightly mineralized. In a small amount there are presented the ions of non-ferrous metals (lead, zinc, copper), potassium and chlorides. From this point of view, the liquid phase to be formed as a result of processing of the goldcontaining quartzites is favorable in its use in the turns. Changes in the ionic content of recirculation waters obtained after sedimentation of metals and used in washing out of dissolved gold and silver are also insignificant. Conclusions The ionic content of the cycle water circulation is insignificantly changed and the liquid phase obtained in processing of secondary quartzites may be used six times in the turn. After additional extraction of silver (NITU "MISIS" know how) final tailings can be used at manufacturing of building materials. As a result of the performed works on the process study of the improvement tails it showed that they may be used as the main raw material for production of silicate walling materials: silicate bricks, products of heavy and foamed concretes, which on their mechanical-and-physical properties meet the requirements of the existing standards. A scope of processed ore, a study of all the factors at desalinisation of precious metals, milling fineness of the ore, influence of the pulp density, concentration potassium cyanide and lime as well as the kinetics of the process, allow insisting that the obtained results will be fully reproduced at the industrial processing of quartzites of the field, but they are also may be used for designing the mobile module unit to extract precious metals for the given type of ores.. References Austin and Luckie, 1972 .Estimation of non-normalized breakage distribution parameters from batch grinding Powder Technology, 5 (5) , pp. 267–277 Austin L.G., Trimarchi, T. and Weymont, N.P.,1977 .An Analysis of some cases of NonFirst-Order Breakage Rates: Powder Technology, 17:109–113 Austin, L.G., 1982, Rate Equations for Non-Linear Breakage in Mills Due to Materials Effects: Powder Technology, 31:127-133 San Luis Potosí, México 13-15 August, 2015 Austin, L.G., and Klimpel R.R., 1984a, Modeling for Scale up of Tumbling Ball Mills: Control ´84, J.A. Herbst (eds.), p. 167-184, SME/AIME, NY Austin, L.G., Klimpel, R.R., Luckie, P.T., 1984b, Process engineering of size reduction, Chapter 9, Methods for Direct Experimental Determination of the Breakage Functions, SME-AIME, New York, USA,. NOTES: Tables should bring their description on the top in the order of appearance, as shown in the example. Figures should bring their description on the bottom in the order of appearance, as shown in the example. All the figures must be in separated files in jpg, png or tiff format. Figures Figure 1. The scheme of devices’ chain during the pilot testing of cyanidation and scheme of the pulp’s countercurrent decantation in the thickeners’ system San Luis Potosí, México 13-15 August, 2015 Tables Table 1. Assay of precious metals and the main impurities in solutions of ore processing Product name Metals’ Assay cobalt copper nickel lead zinc of 1,08 6,12 14,0 <0,53 0,087 <0,001 <0,001 0,0012 First thickener owerflow going 0,46 on sorption 2,53 19,0 <0,38 0,003 <0,001 <0,001 0,0018 0,6 2,3 <0,12 <0,0007 <0,001 <0,005 0,0007 gold cobalt Mg/mL silver Mg/L * Solution cyanidation Degolded solution(owerflo w after sorption on resin АМ-2B ) Not detec ted San Luis Potosí, México 13-15 August, 2015