ara ion chromatography sop - Atmospheric Research & Analysis

advertisement

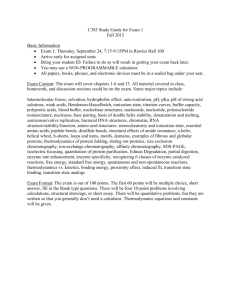

ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 Standard Operating Procedure Using Ion Chromatography for the Analysis of Anions & Cations in Ambient Air Particulate Matter Effective Date:10/30/2007 Version 1.0 Reviewed By:__________________________ Technical Director Approved By:_________________________ Author: Mike Fort_______________________ Page 1 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 TABLE OF CONTENTS Page Table of Contents…………………………………………………………………………………………………………………………...........2 1.0 Scope and Application……………………………………………………………………………………………………………………….3 2.0 Summary…………………………………………………………………………………………………………………………………………..3 3.0 Definitions…………………………………………………………………………………………………………………………………………3 4.0 Interferences…………………………………………………………………………………………………………………………………….5 5.0 Safety………………………………………………………………………………………………………………………………………………..6 6.0 Equipment & Supplies……………………………………………………………………………………………………………………….6 7.0 Eluent Generation……………………………………………………………………………………………………………………………..7 8.0 Calibration & Standardization……………………………………………………………………………………………………………8 9.0 Sample collection, preservation, shipment, storage………………………………………………………………………….9 10.0 Quality control & Quality assurance………………………………………………………………………………………………..9 11.0 Filter/denuder extraction………………………………………………………………………………………………………………10 12.0 Ion Chromatography analysis………………………………………………………………………………………………………..11 13.0 Calculations…………………………………………………………………………………………………………………………………..12 14.0 Method Performance…………………………………………………………………………………………………………………...12 15.0 Maintenance…………………………………………………………………………………………………………………………………12 16.0 Pollution Prevention……………………………………………………………………………………………………………………..13 17.0 Waste Management……………………………………………………………………………………………………………………..13 18.0 References…………………………………………………………………………………………………………………………………….13 Page 2 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 1.0 Scope and Application This procedure is for the analysis of anions and cations by ion chromatography collected on filter samples located within the southeast United States. It is applicable for fine and course atmospheric particles. Fine particles being less than 2.5microns is size and coarse particles being 2.5-10microns is size. The sizes of filters used to capture the particulate matter are 47mm and 37mm respectively. The air samples are collected by site operators and sent to the laboratory for analysis. The samplers used are Particle Composition Monitors (PCM). 2.0 Summary This method covers the simultaneous instrumental analysis of anions and cations by dual channel ion chromatography. The filters are sent to the lab from the site operators in the field and equilibrated in an ISO-6 clean room before extraction and analysis. Filters are extracted in DI water and injected into the calibrated ion chromatography system for quantitation. The ions are speciated and detected by passing thru a guard column, analytical column, suppressor and conductivity detector. Data acquisition is acquired thru the use of Chromeleon software provided by Dionex. Below is a list of anions and cations that may be quantitated with this standard operating procedure: ANIONS CATIONS Bromide Ammonium Bromate Calcium Chlorate Lithium Chloride Magnesium Chlorite Potassium Fluoride Sodium Nitrate Nitrite Ortho-phosphate Sulfate 3.0 Definitions Batch: Indicates a volume of filters/denuders (20 or less) to signify an extraction batch. A new batch is generated for every 20 samples extracted. If a batch was generated with less than 20 samples on one day then a new batch must be created the following day. Page 3 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 Calibration Blank (CB): A solution that has been prepared in the laboratory along with the calibration standards using all the reagents involved in calibrating the IC. The blank must match the matrix of the calibration standards. This would be just DI water in this case. The CB may be involved in the linear regression calculation based upon the operators settings. Calibration standard (CAL): A standard prepared in the laboratory that contains DI water plus a certain concentration of the analytes of interest. These are usually made fresh daily. More than one calibration sample is used to calibrate the Ion Chromatography system. This is usually 3 or more and a calibration blank (CB). Continuing Calibration Verification Standard (CCV): This standard is the midpoint of the calibration curve. This is for the validation of linearity and continuous analysis of the analytical sequence. The CCV is run after the initial calibration and before the continuing calibration blank (CCB). Continuing Calibration Blank (CCB): This standard is used to verify the continuing validation of low end linearity and contamination during the analytical sequence. It also serves as a good indicator of S/N values over time. The CCB is run after the CCV, at a 10% frequency thereafter and at the end of the analytical sequence. Lab Blanks or Trip Blanks (LB or TB): These blanks consist of Teflon 47mm and 37mm filters. The blanks will be run per lot (typically 100 filters per lot). One blank will be selected from the lot and analyzed for anions and cations. The ions quantitated will represent the background inherent in the respective lot of filters tested. Field Blanks (FB): This type of blank will be sent out to the field from the laboratory. The filter will be exposed to passive sampling in order to represent any contamination in the field. The blank will then be shipped back to the lab for analysis and treated as an actual sample. Approximately 10% of all samples are designated as field blanks (10 out of 100). Field Duplicates or Collocated Samples (FD & C1 & C2): These are two separate samplers collecting individual filter samples at the same time, location and same model of sampler. Usually, the only difference will be the volume collected. Analysis of these duplicates contains information on sampling efficiency, storage and preservation. These will be on an as needed basis or the frequency determined by the technical director. Replicates may be run on the duplicates to determine instrument precision. Laboratory Control Sample (LCS): This is a spiked sample (namely DI water) carried throughout the entire extraction and instrumentation process to simulate method precision and accuracy. This sample is spiked with a known amount of analytes to be determined. Laboratory Control Sample Duplicate (LCSD): Sample spiked with a known amount of analytes. This sample is carried throughout the extraction and instrumentation process to simulate method precision and accuracy. The LCSD may or may not be determined due to lack of sample volume. Matrix Spike (MS): A certain known amount of concentrated analytes spiked onto a sampled filter. This filter is then carried throughout the extraction process and analyzed to determine the amount recovered. The amount recovered is calculated and compared to the original values in the unspiked sample. This is used for precision and accuracy, as well as, an indicator of the matrix spike recovery limits. Page 4 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 Matrix Spike Duplicate (MSD): A certain known amount of concentrated analytes spiked onto a sampled filter. This will be an additional spike from the filter selected to do the matrix spike. A duplicate is done to observe method precision. The percent recovery is calculated from the original values of the unspiked sample. The results of the MS/MSD are calculated and compared. The precision and bias are control charted on an ongoing basis. There may or may not be any matrix spike duplicates due to the lack of sample volume. Laboratory Reagent Blank, Method Blank, Prep Blank (LRB,MB,PB): These terms are all used interchangeably. They are the same unless otherwise stated. One LRB, MB or PB will be run per batch of 20 samples or less. This blank is an aliquot of water carried throughout the extraction/analytical process just like a real sample. It’s used to signify background contamination or ions that are present in the laboratory environment. Linear Range Standard (LRS): A standard prepared in the laboratory using a known concentration of an analyte that establishes the extrapolated range of the calibration curve. Each anion and cation of interest must establish this linear range criterion. This end point is used to extrapolate the highest point in the calibration curve to this linear range standard. Method Detection Limit (MDL): The lowest concentration of an analyte that can be quantified and reported with 99% confidence that the analyte concentration is greater than zero. A good starting point for the MDL is 3 to 5 times the IDL. Method Reporting Limit (MRL): This is ascertained by multiplying the MDL by 3 or 5. Particulate Matter (PM): General term used to describe air born particles that are caused by anthropogenic processes that contribute significantly to air pollution. Quality Control Standard (QCS): A standard used to check the validity of the calibration curve. The QCS is from a different manufacturer than the calibration standards. The QCS is usually made up of multiple analytes at the same or differing concentrations. Duplicates: Two samples extracted and analyzed with the same origin. These samples are used for method precision. 4.0 Interferences Interferences are laboratory, instrument, operator or matrix born. These can be eliminated by taking special precautions while preparing your sample to be analyzed. Anything that comes in contact during sample prep and analysis could be a potential interference. However, co-elution interferences are most common and are corrected by diluting or lowering the eluent strength. Interferences are corrected by having 100% resolution between peaks of interest (i.e. no overlap) over a small and large range of concentrations. 4.1 Filter samples suspected of particles larger than 0.45micron. Filter solutions with particles larger than 0.20micron. These particles may clog up the capillary lines in the Ion Chromatography system. 4.2 If any ClO2 is suspected in the sample, purge the sample with an inert gas (i.e. Argon, Nitrogen). Residual ClO2 may form ClO3 prior to analysis. 4.3 To inhibit bacteria growths in extracts try to refrigerate as much as possible. Page 5 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 4.4 Some low molecular weight amines may have retention times similar to the cations of interest. Trimethylamines, triethylamines etc…. 4.5 High levels of Na may interfere with NH4+. This will be validated during the initial demonstration by running high levels of Sodium. 4.6 The acidity of the extract can cause problems if it’s lower than 2.0 H+ (pH). Historically, filter extracts pH should be between 4.00-6.00 H+ (pH). The acidity of extracts shouldn’t be a problem. 4.7 Use plastic ware for solutions, standards and prepared samples since Na is a common contaminant and may be leached from glassware. 5.0 Safety: Laboratory personnel are responsible for wearing appropriate attire while performing this operational procedure. Material Safety Data Sheet (MSDS) should be available and encouraged to explore. Be aware of eye wash and spill cleanup locations at all times. Chemicals should be handled in a fume hood where applicable. 6.0 Equipment and Supplies: This SOP is applicable to analysts that are familiar with the operation and execution of running the Dionex Ion Chromatography system. For a more detailed overview consult the Dionex operations manual. 6.1 Ion Chromatograph Dionex Model ICS-3000 6.2 Below is an example of IC operating conditions. These may change for future analysis. Sample loop volume 100uL for Anions & Cations Analytical Column Anions: Dionex, Ion Pac AS18 Cations: Dionex, Ion Pac CS16 Guard Columns Anions: Dionex, Ion Pac AS18 Cations: Dionex, Ion Pac CG16 Eluents Anions: 10-45mM Potassium Hydroxide Cations: 26mM Methanesulfonic Acid Page 6 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 Eluent flow rates: Anions: 1.0mL/min Cations: 1.5mL/min Data acquisition software: Dionex Chromeleon 6.3 Volumetric flasks 6.4 Mechanical shaker 6.5 Ultrasonic bath 6.6 Nylon filters, Teflon filters or Quartz filters 6.7 Teflon tweezers 6.8 Balance 6.9 PE storage bottles 6.10 Beakers 6.11 Chemicals: All chemicals must be shown to be pure and free from potential interfering artifacts. This is proven by running LRB, MB etc… 6.11.1 Lithium Hydroxide 6.11.2 Carbonate/bicarbonate 6.11.3 Methanesulfonic Acid 6.11.4 Potassium Hydroxide 6.11.5 Sodium Hydroxide 6.11.6 Nanopure ASTM Type 1 deionized water 7.0 Eluent Generation: The Dionex system uses manufactured cartridges for the generation of the eluents. This eliminates errors associated with manual eluent generation. The concentration is programmable through the Chromeleon software. Methanesulfonic Acid is used for the cation eluent. Potassium hydroxide is used for the anion eluent. Each cartridge contains 900mL of the appropriate concentrated solution. Page 7 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 8.0 Calibration &Standardization: 8.1 Use of NIST traceable standards is a must. All volumetrics used must be class A either plastic or glass. 8.2 The pipettes used for making standards must be of known accuracy. 8.3 All standards must be prepared using Nanopure ASTM Type 1 Deionized water. 8.4 Working and control standards must be recorded and documented throughout the analytical process. 8.5 All standards will be stored in the refrigerator until ready for use at 4 degrees centigrade. Anion & Cation Stock Standards: Ion Concentration(ppm) Bromate 1000 Bromide 1000 Chlorate 1000 Chloride 1000 Chlorite 1000 Fluoride 1000 Nitrate 1000 Nitrite 1000 o-Phosphate 1000 Sulfate 1000 Ammonium 500 Calcium 500 Lithium 500 Magnesium 500 Potassium 500 Sodium 500 Page 8 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 8.6 The QCS will be from a different source than the suppliers of the stock solutions. The QCS will be diluted to fit into the calibration range. 8.7 Working standards will be prepared from standard stocks. Working standards will be valid for 21 days from time of preparation or otherwise noted. 8.8 Cations and Anions will have a minimum of three points and a blank to establish the calibration curve. More points may be needed to establish linearity for a given anion or cation. 8.9 Once calibrated, each analyte must have a correlation coefficient of 0.995 or greater to establish linearity. 8.10 Ammonium is expected to be non linear. Ammonium is calibrated using a quadratic equation. 9.0 Sample Collection, Preservation, Shipment, and Storage: 9.1 Filters are collected using differing PCM air samplers (i.e. FRM, PCM1, Coarse FRM, Dichotomous, and CA Denuder). 9.2 No preservation is necessary (i.e. filters). 9.3 Samples are collected at the end of each sampling period (i.e. daily, 1/3, 1/6) and are shipped/stored at <4oC prior to analysis (except during equilibration and weighing). 9.4 Samples are stored in appropriate containers and exposed as little as possible during sample processing. 9.5 Samples that are extracted are analyzed immediately or kept in refrigerator storage for further analysis. 10.0 Quality Control & Quality Assurance: QA/QC Frequency Acceptance Limits LRB One per batch <MDL, PQL or MRL LCS/LCD One per batch +20% LCD is sample volume dependent. QCS 1 per calibration +10% ICV/CCV 1 after calibration curve, +10% 1 every ten samples 1 at the end of run Page 9 of 13 ARA Ion Chromatography Analysis Revision 0.0 ICB/CCB 10/30/2007 1 after calibration curve, <MDL, PQL, MRL 1 every ten samples 1 at the end of run FD Site specific RPD < 20% Analyte concentration has to be greater than 5 * the MDL in order to quantitate RPD. MS/MSD 1 per batch MSD is sample volume dependent. 100+20%, Spike has to be at least 2 * the analyte concentration in order to calculate recovery. 10.1 Initial demonstration (ID) of instrument capabilities must be determined prior to analyzing any samples. This consists of creating and validating MDL’s, linear calibration ranges and the analysis of the QCS. 10.2 Method detection limits (MDL) are established for every analyte of interest. Spike 7 to 10 filters with analyte(s) and process thru prep method. Run replicates on calibrated instrument and calculate MDL’s based on the student’s t value for a 99% confidence level and a standard deviation estimate with n-1 degrees of freedom. MDL= t * s! 10.2.1 MDL’s should be determined whenever significant instrument repair occurs, once every 6 months or when a new operator takes over the analysis. 10.2.2 If MDL’s fail initial criteria then a new set will be created and analyzed. 10.3 Linear Range Standards (LRS) should be determined initially, whenever significant instrument repair occurs, once every 6 months or when a new operator takes over the analysis. 10.3.1 (LRS) Fortify ultra pure water with high concentrations of cations or anions and analyze for linearity. The analyte values must be +10% of the true value to validate the extrapolated linear calibration range. 10.4 Quality Control Sample (QCS) is used to verify the calibration curve and meet data quality objectives. The QCS is run at the beginning of every sequence and must be within +10% of the true value in order to continue with the analytical run. If the QCS fails then calibration curve is invalid, made up incorrectly or could be contaminated. If the QCS fails a second time remake the QCS and calibration curve standards. The QCS should be run after the ICV/CCV. 10.5 Once the initial demonstration is accomplished. The instrument is ready for analysis. 11.0 Filter/(Citric Acid) Denuder extraction: 11.1 Powder less gloves, Lab coats and safety glasses must be worn while performing this procedure. 11.2 Prepare a run log of 20 filters/denuders or less. Page 10 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 11.3 Gather punches, filters or denuders for preparation from freezer, refrigerator or from ambient storage. 11.4 Make sure all samples/denuders to be extracted are labeled correctly. 11.5 Record samples/denuders in extraction log notebook (i.e. Date, time, method, analyst, final volume etc…). 11.6 Using PTFE tweezers carefully take punch or filter out of petri dish and insert into extraction vessel. Cap and label the vessel. Uncap and add 25mL of ultra pure deionized water to each 50mL extraction vessel using a plastic volumetric cylinder(polypropylene, Nalgene etc…) or a calibrated high volume pipette. Repeat this procedure for each punch or filter. Make sure to wipe the tweezers with Kim wipes before and after each use. 11.6.1 Transfer prepared samples to ultrasonic bath using appropriate racks. Make sure that the water level in the bath is higher than the level in the extraction vessel. 11.6.2 Sonicate all samples for 60 minutes. 11.6.3 After sonicating, secure caps and place samples in a mechanical shaker for 60 minutes. Remove samples from mechanical shaker and wipe dry. Refrigerate all samples until ready to analyze. 11.7 Original sample extracts will be refrigerated up to 6 months then discarded. 11.8 The CAD is extracted two times with 10mL of ultrapure deionized water. Uncap the CAD and add first aliquot of water. Shake, and then pour into amber colored wide mouthed bottle. Add second aliquot of water to CAD denuder. Shake, and then add to first aliquot in amber colored wide mouthed bottle. Final extract should be 20mL. Denuder extract is ready for analysis. 11.9 Prepare batch QC alongside samples and denuders (i.e. LRB, LCS anion-cation, LCD if applicable, MS anion-cation, MSD if applicable, FD etc…). 12.0 Ion Chromatography Analysis: 12.1 Power up the IC modules and open the Chromeleon software on the associated computer. 12.2 Open method and setup eluent reservoirs. 12.3 Setup the piston seal washing system to rinse the Single pump or dual pump. Or Both! 12.4 Start and prime the pumps if necessary. 12.5 Set the pump limits. The high system pressure for the DP/SP is 3000psi and the low system pressure is 200psi. Pumps will shut down when limits are above 3000psi or below 200psi. 12.6 Start the eluent generator and set the desired concentrations. 12.7 Start the detector compartment and or temperature control (method specific). 12.8 Equilibrate the IC system. Watch the detector signal to monitor the background level. Auto zero if needed. Page 11 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 12.9 Observe pump pressure. Should be stable (2000-3000psi). 12.10 Method created and loaded. All set points checked and ready for analysis. 12.11 Load auto sampler with prepared extracts. 12.12 Create sequence and start run. 12.13 Monitor analytical sequence and perform data reduction as needed. 12.14 Make sure all QA/QC is adhered to. 12.15 If any problems occur during run, stop the analysis and recalibrate or perform corrective action procedures. 13.0 Calculations: 13.1 The Chromeleon software calculates concentrations using linear regression or quadratic equations. The user can specify what units to use (i.e. ng/L, ng/m3, etc…). Manual calculations will be performed to validate instrument mathematics. 13.2 The QC samples will be calculated in real-time/and or later submitted for further compliance. 13.3 If sample concentrations exceed the LRS then dilute into range and re-analyze. 13.4 Perform data integration as necessary (baseline drift, poor peak shape, etc…) 14.0 Method Performance: 14.1 Work in progress, LRB, FD, LCS, MS etc… 15.0 Maintenance: 15.1 Check for leaks. If the pump pressure starts to differentiate it’s probably the piston seals are leaking. Remove pump heads and replace. 15.2 Inspect/fill eluent reservoirs. Check for cleanliness and replace when necessary. 15.3 Empty waste container as needed. 15.4 Fill seal wash reservoir as needed. 15.5 Keep track of the Eluent Generator (EG) cartridge expiration date and remaining lifetime in the EG control panel. Replace cartridge as necessary. 15.5 Monitor the Detector Chromatography Module (DC) for leaks and spills. Clean area as needed. Replace the sample loop as needed. The Dionex preventative maintenance kit for (DC) module is P/N 061796. Dionex recommends this annually. 15.6 Check the Thermal Compartment for leaks and spills. Isolate and repair leaks. Page 12 of 13 ARA Ion Chromatography Analysis Revision 0.0 10/30/2007 15.7 Check all lines to the IC system daily and check for leaks. Replace any lines that are crimped or discolored. Sample flow rate is crucial for optimum daily performance. 15.8 The analyst should record all maintenance activity in the instrument log book. Remember to sign and date each entry and document what was performed. 16.0 Pollution Prevention: 16.1 This procedure uses non toxic chemicals at low concentrations (i.e. dilute salts and acids) so the pollution factor is very low. To keep pollution at a low level, look for safer (less pollutive) alternative chemicals to use in future analyses and minimize volume whenever possible. 17.0 Waste Management: 17.1 All reagents, waste solutions and standards are stored in safety storage cabinets. All waste is characterized before disposal and kept in appropriate waste drums. Hazardous waste should be disposed of by qualified waste disposal company (i.e. Clean Harbors). 18.0 References: Dionex manual, ICS-3000 Ion Chromatography System Manual Document No. 065031 Revision 03 September 2006 Method 300.0 “Determination of Inorganic Anions by Ion Chromatography” John D. Pfaff, USEPA Method D6919-03 “Standard Test Method for Determination of Dissolved Alkali and Alkaline Earth Cations and Ammonium in Water and Wastewater by Ion Chromatography” ASTM Annual book of standards, Vol 11.01 September 2003 SOP MLD064 “Standard operating Procedure for the analysis of anions and cations in P.M.2.5 Speciation Samples by Ion Chromatography” California Air & Resource Board (CARB) SOP “IC analysis of Ambient Air PM” DEQ state of Oregon, February 2003 Method 300.1 “Determination of Inorganic anions in drinking water by Ion Chromatography” USEPA 1997 Page 13 of 13