ACC 561 Week 3 DQ 2

advertisement

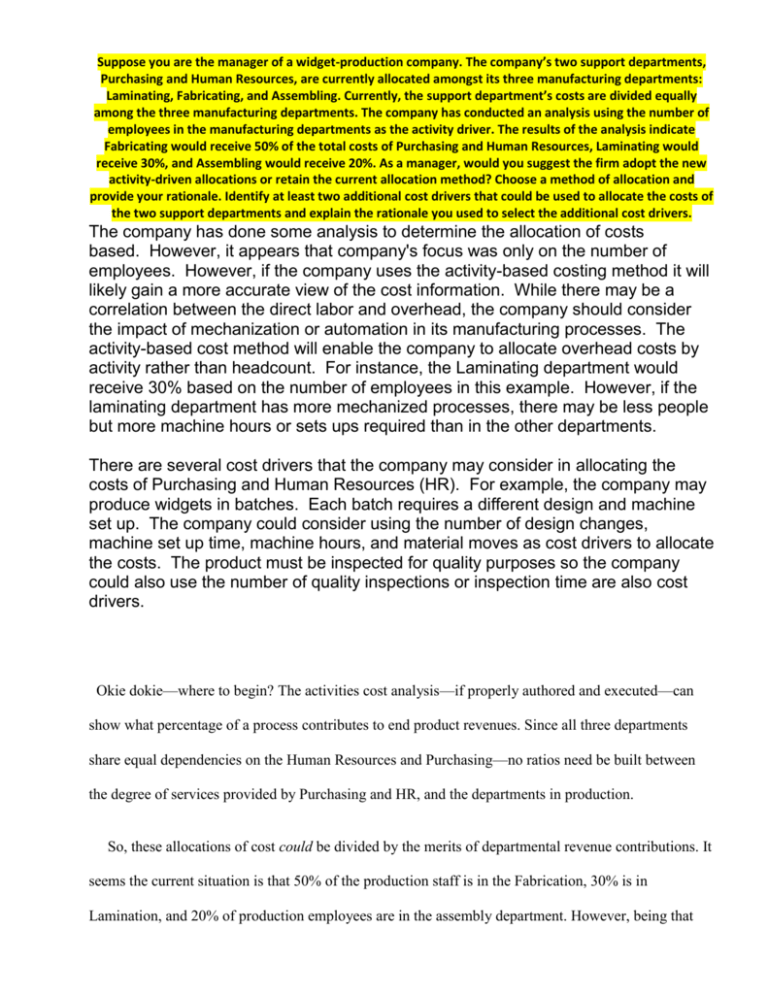

Suppose you are the manager of a widget-production company. The company’s two support departments, Purchasing and Human Resources, are currently allocated amongst its three manufacturing departments: Laminating, Fabricating, and Assembling. Currently, the support department’s costs are divided equally among the three manufacturing departments. The company has conducted an analysis using the number of employees in the manufacturing departments as the activity driver. The results of the analysis indicate Fabricating would receive 50% of the total costs of Purchasing and Human Resources, Laminating would receive 30%, and Assembling would receive 20%. As a manager, would you suggest the firm adopt the new activity-driven allocations or retain the current allocation method? Choose a method of allocation and provide your rationale. Identify at least two additional cost drivers that could be used to allocate the costs of the two support departments and explain the rationale you used to select the additional cost drivers. The company has done some analysis to determine the allocation of costs based. However, it appears that company's focus was only on the number of employees. However, if the company uses the activity-based costing method it will likely gain a more accurate view of the cost information. While there may be a correlation between the direct labor and overhead, the company should consider the impact of mechanization or automation in its manufacturing processes. The activity-based cost method will enable the company to allocate overhead costs by activity rather than headcount. For instance, the Laminating department would receive 30% based on the number of employees in this example. However, if the laminating department has more mechanized processes, there may be less people but more machine hours or sets ups required than in the other departments. There are several cost drivers that the company may consider in allocating the costs of Purchasing and Human Resources (HR). For example, the company may produce widgets in batches. Each batch requires a different design and machine set up. The company could consider using the number of design changes, machine set up time, machine hours, and material moves as cost drivers to allocate the costs. The product must be inspected for quality purposes so the company could also use the number of quality inspections or inspection time are also cost drivers. Okie dokie—where to begin? The activities cost analysis—if properly authored and executed—can show what percentage of a process contributes to end product revenues. Since all three departments share equal dependencies on the Human Resources and Purchasing—no ratios need be built between the degree of services provided by Purchasing and HR, and the departments in production. So, these allocations of cost could be divided by the merits of departmental revenue contributions. It seems the current situation is that 50% of the production staff is in the Fabrication, 30% is in Lamination, and 20% of production employees are in the assembly department. However, being that the revenues generated by the sale of end products fund these ancillary departments—a cost analysis should be used to establish which processes generate profits for the company. It must be possible to do this—appraise and assign process cost/revenue ratios to each department. Perhaps the department that produces the highest percentage of profit should receive a proportional percentage of ancillary department cost. This is merely an alternative to the “number of employees per department” type of costy allocation. Hope this is right…