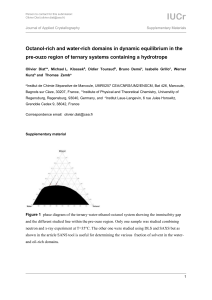

Supporting Information Ternary phase diagram and fiber

advertisement

Supporting Information Ternary phase diagram and fiber morphology for nonsolvent/DMAc/polyamic-acid systems Chaoqing Yin, Jie Dong, Zhentao Li, Zixin Zhang, Qinghua Zhang* State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, People’s Republic of China *Corresponding author: Q. Zhang, Tel/Fax: 0086-21-67792854. E-mail: qhzhang@dhu.edu.cn THEORY 1. Thermodynamics of ternary systems Tompa[1] is the first person who applied Flory-Huggins model to analyze nonsolvent/solvent/polymer ternary systems. According to this theory, Gibbs free energy of mixing, ∆Gm, can be expressed as follows: The subscripts refer to nonsolvent (1), solvent (2) and polymer (3), ni and i are the number of moles and the volume fraction of component i, respectively. R and T are the gas constant and absolute temperature, respectively. gij is a concentration-dependent binary interaction parameter between components i and j. However, in most ternary systems, independence of concentration is taken into consideration for the thermodynamic evaluations of nonsolvent/polymer and solvent/polymer interaction parameters, g13 and g23. Therefore, in the following equations, χ13 and χ23 are used to replace g13 and g23. The solvent-nonsolvent parameter, g12, is assumed to be a function of 2, with 2= 2/( 1+ 2) by Pouchlý et al.[2]. 1.1. Binodal curve The chemical potential of a species in a mixture can be defined as the slope of the Gibbs free energy of the system with respect to a change in the number of moles of just that species. Thus, the chemical potential of component i can be expressed as follows: Based on the expression of ∆Gm (Eq. 1) and the definition of chemical potential (Eq. 2), the following three equations are derived for the chemical potentials of the components in the mixture: Where, ∆μi is the difference between the chemical potential of component i and pure state, and vi is the molar volume of component i. The condition for liquid-liquid equilibrium is: Where, the subscripts denote dilute phase (A) and concentrated phase (B), respectively. According to mass conservation law, it obeys the following equation: Tie lines connect the pair of equilibrium compositions in the polymer-rich phase (1,A, 2,A, 3,A) and polymer-poor phase (1,B, 2,B, 3,B). It should be noted that only binary interaction parameters are considered. To specify the tie line compositions, these six unknowns can be obtained. Substituting Eqs. (3)-(5) in Eq. (6) provide three equations, and the other two equations are given by Eq. (7). There are five relations among the six unknown compositions, the polymer composition in the polymer-poor phase, 3,B, is set as an independent variable, and the Newton-Raphson method can be used to solve the remaining system. 1.2. Spinodal curve A curve that separates a meta-stable region from an unstable region in the coexistence region of a binary fluid is the so-called spinodal curve, which is thermodynamically defined as: The equation for the spinodal is: Where , therefore, the relationship for ∆Gm obeys the following: Also, the components of ternary system obey the volume conservation law (Eq. 13). When the interaction parameters are available, substitution of Eqs. (10)-(12) in Eq. (9) along with Eq. (13) results in two equations with three variables, which can be solved numerical by choosing one of the variables (in our case 3) as the independent variable. This is done by using the same numerical procedure as for the binodal. 1.3. Critical point The critical point where the binodal and spinodal curves intersect can be expressed as[1]: The critical point composition meets the following equation, and it can be solved by the similar procedure used for spinodal: 2. Evaluation of the binary interaction parameters 2.1. Nonsolvent/solvent interaction parameter The nonsolvent-solvent interaction parameter, g12, is determined from the excess Gibbs free energy (∆GE) data using the following equations[3]: Where ni and i are the number of moles and the volume fraction of component i, respectively. By Eq. (17), g12 can be calculated as a function of 2, and ∆GE can be directly obtained from experimental data. But a few solvent/nonsolvent systems have experimental data on ∆GE available. ∆GE can be obtainde from activity coefficients data, which can be calculated based on Universal Quasichemical Functional Group Activity Coefficient (UNIFAC) model[4-8]. The original UNIFAC model, which combines the functional group concept with a model for activity coefficients based on an extension of the quasi-chemical theory of liquid mixtures, was proposed by Fredenslund et al. in 1975.[8] The activity coefficient is expressed as a function of composition and temperature, it is calculated as a sum of the combinatorial and residual parts: ln γi = ln γi (c) + ln γi (R) (18) Expressions of combinatorial part are as follows: ln γi (c) = ln ϕi θi ϕi + 5q i ln + li − ∑ xj lj xi ϕi xi (19) j li = 5(ri − q i ) − (ri − 1) (20) Where subscripts i and j denote the components, k is the group, i and θi are the volume fraction and area fraction of component i, respectively, and xi is the mole fraction of component i. Parameters of ri and qi are relative to molecular van der Waals volumes and molecular surface areas, respectively, and they are calculated as the sum of the group volume and group area parameter, Rk and Qk, as Eq. (22) shows. θi = x i qi ∑j xj qj xi ri ∑j xj rj (21) q i = ∑k νk (i) Q k (22) ϕi = ri = ∑k νk (i) R k Where νk (i) is the number of groups of type k in molecule i. The group parameters Rk and Qk are available in literatures. Expressions of residual parts are as follows: ln γi (R) = ∑ νk (i) [ln Γk − ln Γk (i) ] (23) k Where Γk is the group residual activity coefficient, and Γk(i) is the residual activity coefficient of group k in a reference solution containing only molecules of type i. ln Γk = Q k [1 − ln (∑ θm ψmk ) − ∑ m ln Γk (i) = Q k [1 − ln (∑ θm m (i) ψmk ) − ∑ m Qm Xm θm = ∑n Q n Xn Xm = ∑i νm (i) xi ∑i ∑k νk (i) xi θm ψkm ] ∑n θn ψnm m θm (i) = X m (i) θm (i) ψkm ∑n θn (i) ψnm Q m Xm (i) ∑n Q n Xn (i) νm (i) = ∑k νk (i) (24) ] (25) (26) (27) ψmn = exp (− amn ) T (28) Xm is the fraction of group m in the mixture. ψmn is decided by amn, characterizing the interaction between groups n and m. Ethanol was divided into three groups: -CH3, -CH2 and -OH; ethylene glycol was divided into four groups: 2×-CH2 and 2×-OH, DMAc was divided into two groups: -CH3 and –CON(CH3)2. For each group-group interaction, there are two parameter: amn≠anm, and they are also available in literatures, as listed in Table S-1. 1 2 3 4 5 Table S-1. The interaction parameters anm between groups n H2O -CH3 -CH2 -OH -CON(CH3)2 m H2O 0 300 300 -229.1 835.6 -CH3 1318 0 0 986.5 390.9 -CH2 1318 0 0 986.5 390.9 -OH 353.5 156.4 156.4 0 -382.7 -CON(CH3)2 -509.3 27.97 27.97 394.8 0 2.2. Solvent/polymer and nonsolvent/polymer interaction parameters Solvent/polymer interaction parameter (χ23) can be determined by measuring the activity of the solvent via a variety of techniques including light scattering[9], osmotic pressure[10], gas-liquid equilibrium[11] and viscometric method[12]. The nonsolvent/polymer interaction parameter (χ13) can be evaluated via simple equilibrium swelling method[13]. However, these methods are not quite suitable for systems in our study due to the low vapor pressure of DMAc, high volatility of ethanol and easy degradation of PAA in water. Therefore, it is a good way to calculate χ23 and χ13 via Hansen solubility parameter theory[14] (Eq. 29). χ12 = α V1 2 [(δd1 − δd2 )2 + 0.25(δp1 − δp2 ) + 0.25(δh1 − δh2 )2 ] RT (29) Where δd, δp and δh are the dispersion force, polar force and hydrogen bond components of the solubility parameter, respectively. In most cases, the results derived from an optimum value of 0.6 are better than an assumed value of one[15]. The δd, δp and δh values of solvent and nonsolvent can be directly obtained in literatures[14] by Lydersen (1955), and the corresponding values for polymers can be derived by Hoy’s method[16]. According to the structure of PAA (Scheme 1), it can be divided into the following groups, and the values of the group contributions are available in literatures, as listed in Table S-2. Table S-2. Values of group contributions Vi/(cm3/mol) △Ti(p) 59.5 13.2 0.019 173 63 7.2 0.013 2 1131 895 28.3 0.073 2 565 415 23.3 0.045 N 0.7 125 125 12.6 0.014 NH 0.7 368 368 11.0 0.031 O 0.3 235 216 6.5 0.018 Groups Numbers CH 13.3 249 C 11.4 CONH COOH The solubility parameters of DMAc, ethanol, water, EG and PAA, which are based on the results of Hoy’s method for estimation, are listed in Table S-3. Table S-3. The solubility parameters of DMAc, ethanol, water, ethylene glycol and PAA Component δd/(MPa1/2) δp/(MPa1/2) δh/(MPa1/2) δ/(MPa1/2) V(ml/mol) DMAc 16.8 11.5 10.2 22.8 92.5 water 15.5 16.0 42.3 47.8 18.0 ethanol 15.8 8.8 19.4 26.5 58.5 EG 17.0 11.0 26.0 33.0 55.8 PAA 15.4 14.8 13.0 25.0 -- 3. Evaluation of the binary interaction parameters To better illustrate the relationship between experimental and calculated data in the ternary systems, the experimental and calculated compositions for PAA/DMAc/H2O, PAA/DMAc/EG and PAA/DMAc/ethanol systems are listed in Table S-4. Table S-4. The experimental and calculated compositions for the ternary systems. CPAA (wt%) Composition ratio(PAA:DMAc:H2O) Experimental Calculated Deviations 0.5 0.50: 85.89: 13.61 0.50: 86.30: 13.20 0.00: 0.41: -0.41 1.5 1.50: 85.70: 12.80 1.50: 86.13: 12.37 0.00: 0.43: -0.43 2.0 2.00: 85.40: 12.60 2.00: 85.80: 12.20 0.00: 0.40: -0.40 2.5 2.50: 85.22: 12.28 2.50: 85.37: 12.13 0.00: 0.15: -0.15 3.0 3.00: 84.90: 12.10 3.00: 85.09: 11.91 0.00: 0.19: -0.19 CPAA (wt%) Composition ratio(PAA:DMAc:ethanol) Experimental Calculated Deviations 0.5 0.50: 67.23: 32.27 0.50: 67.75: 31.75 0.00: 0.52: -0.52 1.5 1.50: 67.02: 31.48 1.50: 67.28: 31.22 0.00: 0.26: -0.26 2.0 2.00: 66.63: 31.37 2.00: 66.91 :31.09 0.00: 0.28: -0.28 2.5 2.50: 66.27: 31.23 2.50: 66.53 :30.97 0.00: 0.26: -0.26 3.0 3.00: 65.79: 31.21 3.00: 66.22: 30.78 0.00: 0.43: -0.43 CPAA (wt%) Composition ratio(PAA:DMAc:EG) Experimental Calculated Deviations 0.5 0.50: 87.30: 12.20 0.50: 87.51: 11.99 0.00: 0.21: -0.21 1.5 1.50: 86.73: 11.77 1.50: 87.15: 11.35 0.00: 0.42: -0.42 2.0 2.00: 86.30: 11.70 2.00: 86.71: 11.29 0.00: 0.41: -0.41 2.5 2.50: 86.29: 11.21 2.50: 86.48: 11.02 0.00: 0.19: -0.19 3.0 3.00: 85.90: 11.10 3.00: 86.09: 10.91 0.00: 0.19: -0.19 Reference 1. Tompa H (1956) Polymer solutions. Butterworths Scientific Publications, London 2. Pouchly J (1989) Sorption equilibria in ternary-systems-polymer mixed-solvent. Pure Appl Chem 61 (6):1085-1095 3. Mulder M (1991) Basic principles of membrane technology second edition. Dordrecht: Kluwer Academic Publishers, Netherland 4. Kuramochi H, Noritomi H, Hoshino D, Nagahama K (1996) Measurements of solubilities of two amino acids in water and prediction by the UNIFAC model. Biotechnol Prog 12 (3):371-379 5. Kan AT, Tomson MB (1996) UNIFAC prediction of aqueous and nonaqueous solubilities of chemicals with environmental interest. Environ Sci Technol 30 (4):1369-1376 6. Fu YH, Orbey H, Sandler SI (1996) Prediction of vapor-liquid equilibria of associating mixtures with UNIFAC models that include association. Ind Eng Chem Res 35 (12):4656-4666 7. Albuquerque LC, Simoes AN, Ventura CM, Goncalves RC, Macedo EA (1996) Infinite dilution activity coefficients predicted from UNIFAC model. new experimental data for the solvolytic reactions of 2-chloro-2-methylpropane in methanol/ethanol, methanol/2-methoxyethanol, and ethanol/2-methoxyethanol. Ind Eng Chem Res 35 (10):3759-3762 8. Lei ZG, Zhang JG, Li QS, Chen BH (2009) UNIFAC Model for Ionic Liquids. Ind Eng Chem Res 48 (5):2697-2704 9. Zeman L, Tkacik G (1988) Thermodynamic analysis of a membrane-forming system water N-methyl-2-pyrrolidone polyethersulfone. J Membrane Sci 36:119-140 10. Fuoss RM, Mead DJ (1943) Osmotic pressures of polyvinyl chloride solutions by a dynamic method. J Phys Chem 47 (1):59-70 11. Vainberg YV, Mokrushina LV, Balashova IM (1999) Infinite-dilution activity coefficients of solvents in solvent-polymer systems from inverse gas-liquid chromatography. Theor Found Chem Eng 33 (4):313-318 12. Qian JW, Rudin A (1992) Prediction of thermodynamic properties of polymer-solutions. Eur Polym J 28 (7):725-732 13. Tan L, Pan D, Pan N (2008) Thermodynamic study of a water-dimethylformamide-polyacrylonitrile ternary system. J Appl Polym Sci 110 (6):3439-3447 14. Hansen CM (2007) Hansen solubility parameters: a user's handbook. CRC Press, Boca Raton 15. Lindvig T, Michelsen ML, Kontogeorgis GM (2002) A Flory-Huggins model based on the Hansen solubility parameters. Fluid Phase Equilibr 203 (1-2):247-260 16. Krevelen DWV, Nijenhuis KT (2009) Properties of polymers: their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Fourth, completely revised edition edn. Elsevier, New York