POWERCARE & SERVICE SOLUTIONS, INC. Hazardous

advertisement

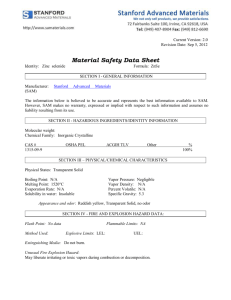

POWERCARE & SERVICE SOLUTIONS, INC. Hazardous Communication Program Approval Document Title Hazardous Communications Program Approval PCSS-60P-0007 April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Rev 2.0 Page 1 of 12 POWERCARE & SERVICE SOLUTIONS, INC. PURPOSE: POWERCARE & SERVICE SOLUTIONS, INC. (PowerCare) is fully committed to providing a safe and healthful work environment for every team member. Sometimes it is necessary for team members to work with or around potentially hazardous substances. In these instances it is important that team members are aware of the substance’s identity, health and physical properties, and the safe work practices required to minimize any potential hazards. To insure team member health and safety, a written Hazard Communication Program has been developed. PROGRAM ADMINISTRATOR: The Manager of Operations for their location is responsible for the overall training and implementations of all safety programs and policies. Training on Hazardous Communication shall be given to all team members. This will include new hires, and existing team members, as required. All documented training shall be kept in the team member’s file along with a copy sent to PowerCare’s Safety Program Administrator. The training provider will maintain a record of each employee’s training record which will include the course name, the team member’s name, and the course completion date. These records shall be maintained for a minimum of five years after the date an individual participated. If you have any questions about our written Hazard Communication Program, please contact The Safety program Administrator at: 10200 Plano Road, Suite 400, Dallas, TX 75238. COMPANY RESPONSIBILITY: It is PowerCare’s responsibility to: Prepare a list of potentially hazardous substances – See Exhibit A Ensure that containers are properly labeled. Maintain and make available to team members a file of Safety Data Sheets (SDS) for each hazardous substance in the workplace. Ensure that team members have the required information and training. Develop and implement a written Hazard Communication Program. TEAM MEMBER RESPONSIBILITY: Active team member participation is essential to the success of the Hazard Communication Program. Team members should be alert to the potential hazards of all the substances in the workplace, consult the Safety Data Sheets (SDS) for the specifics about these hazardous substances, and follow the safe work practices that have been established to protect their health and safety. Team member must be aware of all waste materials when reusing or recycling of any potential hazardous items. Non hazardous recyclable materials such as paper, aluminum, glass, copper, etc. must be placed in the proper containers for disposal or reclamation. Trash bags can be used April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 2 of 12 POWERCARE & SERVICE SOLUTIONS, INC. when there are no containers and must be disposed of in the proper manner. Team members will follow local, state and federal guidelines when disposing hazardous waste. Team members are responsible for assuring that good housekeeping practices are followed. The proper handling, organization, disposal and storage of waste and scrap materials is imperative to minimize potential impacts to the environment as well as to maintain a safe working area. The control of flammable material is essential to prevent fires. Team members working at customer locations must follow all customer policies for trash and debris removal. LIST OF HAZARDOUS SUBSTANCES: A. Every hazardous substance known to be present in the workplace will be listed on the Substance List – Exhibit A B. The name of the substance that appears on this list will be the same as the one that appears on the label and the SDS for that substance. C. The Hazardous Substance List is located on file at each location including POWERCARE & SERVICE SOLUTIONS, INC. 10200 Plano Road, Suite 400, Dallas, TX 75238. LABELING CONTAINERS: A. Each container of a hazardous material used or shipped from our workplace must have a hazard warning label with the following information: Name of chemical (or product name) Name of manufacturer Contact details of manufacturer Appropriate hazard warning B. Portable or secondary containers shall be labeled in the same way. C. The Operations Manager and Safety Coordinator are responsible to ensure that each container label has the appropriate information. D. No label should be defaced or removed unless it is immediately marked with the required information. Any container without a label should be reported immediately. E. The name of the chemical (product name) on the label will be the same name that appears on the Hazardous Substance List and the SDS for that substance. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 3 of 12 POWERCARE & SERVICE SOLUTIONS, INC. SAFETY DATE SHEETS (SDS) A. A SDS containing the information required by the OSHA Hazard Communication Standard will be kept for each substance on the Hazardous Substance List. The SDS will be the current edition as supplied by the manufacturer. B. The Operation Managers and Safety Coordinator are responsible for maintaining the SDS file. The collection of current SDS can be found in the office at this location POWERCARE & SERVICE SOLUTIONS, INC., 10200 Plano Road, Suite 400, Dallas, TX 75238. C. No hazardous substance will be used in the workplace unless an SDS has been obtained first and is on file. D. If new and significant health information about any hazardous substance on the Hazardous Substance List becomes known; a revised SDS shall be obtained and placed on file. Team members who handle or might be exposed to the substance will be notified of any change in the work procedures or personal protective equipment required to protect their health and safety. E. SDS shall be maintained and readily accessible in each work area. When team members are traveling between their primary work location and a customer site, the MSDS can be maintained at the primary work site. However, they shall be available in case of an emergency. SDS must be made available, upon request, to team members, their designated representatives, the in accordance with the requirements of 29 CFR 1910.120(e). COMMUNICATING HAZARDOUS INFORMATION A. TO TEAM MEMBERS 1. All team members working with or potentially exposed to hazardous substances shall be appropriately informed and trained. Training for this topic can be found on our corporate online training page under IB Learning (Green House) web site. The Hazardous Communication course is found under the Safety and Health topic. a. Information includes: April 13, 2012 Requirements of the Hazardous Communication Standard Location of hazardous substance in the workplace Location of the Written Hazard Communication Program, Hazardous Substance list and SSDS. Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 4 of 12 POWERCARE & SERVICE SOLUTIONS, INC. b. Training includes: How to detect the presence or release of a hazardous substance Physical and health hazard of hazardous substances Safe work practices, emergency procedures, and personal protective equipment to minimize exposure to hazardous substances. Explanation of the labeling system, how to read SDS, and where to obtain hazard communication information. 2. This information and training shall be provided at the time of a team member’s initial assignment to work with or around hazardous substances, or when new hazard is introduced into the work area. 3. Before any non-routine task is performed, team members shall be instructed in the potential hazard of the task and be informed of the appropriate work practices to be followed. 4. Team members (and any contractor being employed in the work area) shall be informed of hazardous substances in unlabeled pipes or containers, and of potential hazards involved in the event of exposure to these substances. During normal operations and in the event of an emergency, this information –shall be passed to all contractors involved in the incident. 5. When on a client’s location PowerCare team members shall carry a copy of all Applicable SDS. This SDS information shall be shared with any other contractors on the job site. B. CONTRACTORS 1. Outside contractors will be informed about the hazardous substances and the labeling system they may be exposed to while working in our facility, and how to protect themselves from these substances. 2. Outside contractors shall inform PowerCare manager or foreman on duty about any hazardous substance they may bring into the workplace so that PowerCare team members may receive the necessary information and training to protect their health and safety. 3. The head of the Safety Department and Service Manager is responsible for the exchange of hazard information with outside contractors. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 5 of 12 POWERCARE & SERVICE SOLUTIONS, INC. PROGRAM COMMUNICATION FOR NON-ENGLISH SPEAKING TEAM MEMBERS: While OSHA requires that the written Hazard Communication Program, all SDS, and container labels are written in English. PowerCare will make every effort to communicate the Hazard Communication Program in the language of non-English speakers. Effective communication will be accomplished through any of the following methods or combinations thereof: Training over entire program in team member’s native language through the use of an interpreter/intermediary. Video presentation in the native language of the team member. Written materials (handouts, SDS, container labels) in the native language of the team member, when available and/or accessible. PowerCare will use NFPA, Container Labels, words, pictures to address the appropriate hazard warnings. If you have any questions about our written Hazard Communication Program, please contact The Safety Program Administrator at 10200 Plano Road, Suite 400, Dallas, TX 75238. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 6 of 12 POWERCARE & SERVICE SOLUTIONS, INC. The National Fire Protection Association System (NFPA) is used in industrial plant and storage locations to provide information for the fighting and emergency response personnel. The code numbers, on a scale of 0 for no hazard to 4 for the high hazard, for degree of health hazard, fire hazard, reactivity, and special hazard are written on the label at the time the label is placed into service. The numbers on the following figure were created solely for illustration purposes. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 7 of 12 POWERCARE & SERVICE SOLUTIONS, INC. The hazardous Materials Identification Systems (HMIS) is a registered trademark of the National Paint & Coating Association. The code numbers, on a scale of 0 for no hazard to 4 for high hazard, for degree of health hazard, flammability, reactivity, and recommended personal protective equipment (PPE) are written on the label at the time the label is placed into service. The codes are presented on the figure. The numbers on the figure was created solely for illustration purposes April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 8 of 12 POWERCARE & SERVICE SOLUTIONS, INC. D. Irritant. Noncorrosive material that causes a reversible inflammatory effect on Living tissue by chemical action at the site of contact. E. Oxidizer and Oxidizing Agent. A substance that yields oxygen readily to stimulate the combustion. F. Radioactive. Material that emits radioactive particles or rays, such as many of the materials used in well logging and/or for industrial radiography. The type of placard used relates to the amount of radioactive materials stored in the vehicle or container. G. Toxic. A substance that is harmful to human health. Poisonous. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 9 of 12 POWERCARE & SERVICE SOLUTIONS, INC. Department of transportation (DOT): The following is a partial listing Of the more commonly encountered DOT labels. DOT labels are used on vehicles transporting hazardous materials and on containers used for Transportation. a. Biohazard (Bloodborne Pathogens). Any pathogenic micrtoorganisms that are present in human blood and can infect and cause disease in persons who are exposed to blood containing the pathogen Includes, but is not limited to HIV/AIDS Hepatitis B (HIV). b. Combustible, Flammable 1) Combustible materials with flash points 100 F. 2) Flammable material with flash points less than 100F. C. Corrosive. Causes visible destruction of or irreversible alterations in living tissue by chemical action at the site of contact. Causes a severs corrosion rate of steel. April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 10 of 12 POWERCARE & SERVICE SOLUTIONS, INC. Exhibit A PowerCare Substance List Please reference all SDS sheets for chemicals listed below. SDS sheets can be found at each regional location and at PowerCare’s Safety Administrator corporate office. Some chemicals may be in one or more products, but are listed as individual chemicals for identification purposes. 1) Petroleum Base oil – WD-40 Aerosol 2) Butoxy-1-Ethanol – Liquid Wrench 3) Trimethylbenzene – Liquid Wrench 4) Xylene – Liquid Wrench 5) Toulene 6) Methanol – Crown Lacquer Thinner 7) Butoxyethanol – Crown Lacquer Thinner 8) Acetone – Crown Lacquer Thinner 9) Ethylene Glycol Butyl Ether – Crown Lacquer Thinner 10) Liquefied Petroleum Gas – Gloss Light Machine – paint Rust-Oleum Corp © 11) Xylene – Gloss Light Machine – paint Rust-Oleum Corp © 12) Butyl Acetate – Gloss Light Machine – paint Rust-Oleum Corp © 13) Methyl Ethyl Ketone – Liquid Epoxy Black 14) Carbon Black, amorphous – Liquid Epoxy Black 15) Silica, Amorphous (Crystalline free) – Liquid Epoxy Black 16) Propane – ACE Rust Stop Paint / Sherwin Williams © 17) Mineral Spirits – ACE Rust Stop Paint / Sherwin Williams © 18) V.M. and P. Naphtha – ACE Rust Stop Paint / Sherwin Williams © 19) Lead – Batteries various manufacturers. 20) Lead Dioxide – lead acid Batteries 21) Antimony – lead acid Batteries 22) Arsenic – lead acid Batteries 23) Calcium – lead acid Batteries 24) Tin – lead acid Batteries 25) Silicon Dioxide (Gelled Batteries only) 26) Nickel Oxyhydroxide & Cobalt Hydroxide – Nickel-Cadmium battery 27) Cadmium – Nickel-Cadmium battery 28) Potassium Hydroxide – Nickel-Cadmium battery 29) Dilute Sulfuric Acid – lead acid Batteries April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Page 11 of 12 POWERCARE & SERVICE SOLUTIONS, INC. Date 4/13/12 4/12/13 Revision Description of Change 1.0 Initial release. 2.0 Adding of SDS April 13, 2012 Property of Interstate PowerCare 10200 Plano Road Suite 400 Dallas, TX 75238 Requestor Page 12 of 12