Knoevenagel condensation reactions catalysed by metal

advertisement

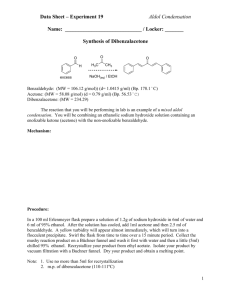

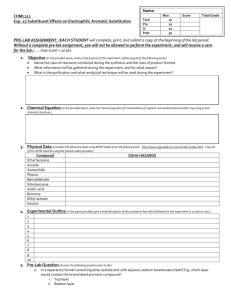

Knoevenagel condensation reactions catalysed by metal-organic frameworks Andrew R. Burgoyne, Reinout Meijboom* Research Centre for Synthesis and Catalysis, Department of Chemistry, University of Johannesburg, PO Box 524, Auckland Park 2006, Johannesburg, South Africa. Tel.: +27 (0)11 559 2367, fax.:+27 (0)11 559 2819;Email: rmeijboom@uj.ac.za Supplementary information Synthesis of Metal Organic Frameworks: Preparation of IRMOF-3: Zn4O(BDC-NH2)3 O OH NH2 DMF + Zn(NO3)2 . 6H2 O NH2 110o C, 18h IRMOF-3: Zn4O(NH2BDC)3 O OH Zn(NO3)2.6H2O (1.5 g, 5.04 mmol) and 2-aminobenzenedicarboxylic acid (0.3 g, 1.68 mmol) were dissolved in 100 cm3 of dimethylformamide (DMF). The solution was heated at 100 oC for 24 hours. Then the mixture was cooled to room temperature and the solvent was decanted and the product was washed three times with fresh DMF. Afterwards the product was left for 24 hours a further two times, after which the crystals which crushed out were left in fresh chloroform. This yielded 50% product [20]. 1H NMR (d6-DMSO, 35% DCl in D2O, 400 MHz, p.p.m.): 7.40 (d, 1H, aromatic), 6.97 (s, 1H, aromatic), 6.90 (d, 1H, aromatic), 2.50 (d6-DMSO). 13C NMR (d6-DMSO, 35% DCl in D2O, 400 MHz, p.p.m.): 170 (carboxylic), 136 (ipso-aromatic), 130 (aromatic). IR (cm1 ): 3296 (νNH2), 3041 (νNH2), 1550, 1503, 1431, 1400 (ν C-O-Zn), 1314, 1054 (νC-N), 654, 896, 852, 808, 772, 726, 670, 621, 617, 614, 606. PXRD (2θ): 7.00, 9.83, 11.31, 13.86, 15.50, 17.94, 19.36, 20.74, 22.71, 24.65, 26.61, 28.34, 30.02, 31.76, 32.91, 34.78, 35.46, 36.23, 37.33. Preparation of MIXMOF: Zn4O(BDC-NH2)0.15(BDC)2.85 O O OH OH NH2 DMF + + Zn(NO3 )2. 6H2O O O OH NH2 110oC, 18h OH Zn(NO3)2.6H2O (11.90g, 40.000 mmol) and 2-aminoterephtalic acid (0.272 g, 1.500 mmol) and benzene dicarboxylic acid (4.734 g, 28.500 mmol) were dissolved in 50 cm3 of DMF. The solution was heated at 40oC (without stirring) for 7 days. After cooling to room temperature, the mother liquor was decanted and crystals washed three times with 10 cm3 of dry DMF (dried over molecular sieves) followed by one rinse with 10 cm3 of CHCl3. The crystals were then soaked in 10 cm3 of CHCl3 for three days with fresh CHCl3 added every day. After three days of soaking, the crystals were stored in the last CHCl 3 until needed. This yielded 10.99 g [7]. 1H NMR (d6-DMSO, 35% DCl in D2O, 400 MHz, p.p.m.): 8.15 (d6-DMSO), 7.12-7.00 (m, 4H, aromatic). 13 C 6 NMR (d -DMSO, 35% DCl in D2O, 400 MHz, p.p.m.): 168 (carboxylic), 135 (ipso-aromatic), 130 (aromatic). IR (cm-1): 3262 (νNH2), 3048 (νNH2), 2936, 2360, 2164, 2034, 1960, 1667, 1570, 1550, 1504, 1375 (ν C-O-Zn), 1316, 1295, 1154, 1133, 1117, 1091, 1062 (ν C-N), 1018, 888, 823, 773, 747, 700, 634, 600, 578. PXRD (2θ): 6.99, 8.94, 9.71, 10.46, 12.77, 13.80, 16.13, 16.47, 16.90, 17.24, 17.80, 19.41, 20.79, 21.88, 23.05, 24.55, 25.38, 26.71, 27.37, 29.00, 29.55. Preparation of UMCM-NH2: Zn4O(BDC-NH2)1.5(BTB)1.5 HO HO O NH2 O DMF NH2 + 85 oC, 2 days HO O HO O O OH Zn(NO3)2.6H2O (1.415 g, 4.755 mmol) and 2-amino-1,4-benzenedicarboxylic acid (0.144 g, 0.793 mmol) and 4,4’,4’’-benzene-1,3,5-triyl-tribenzoic acid (0.347 g, 0.793 mmol) were dissolved in 100 cm3 of DMF. The solution was heated to 85 oC for 2 days and left to cool to room temperature. The mother liquor was decanted and washed three times with 12 cm3 DMF. Following this the product was soaked in chloroform for 3 days, washing with new chloroform every day. The product was dried under high-vacuum and yielded 2.34 g [8]. 1H NMR (d6-DMSO, 35% DCl in D2O, 400 MHz, p.p.m.): 8.37 (d6-DMSO), 7.98-7.32 (m, 15H, aromatic). IR (cm1 ): 3445 (νNH2), 3339 (νNH2), 2962, 2360, 1655, 1578, 1494, 1381 (ν C-O-Zn), 1258, 1091, 1061 (νC-N), 1016, 861, 798, 704, 660, 577, 562, 553, 542, 530. PXRD (2θ): 4.82, 7.02, 7.21, 8.97, 9.88, 10.91, 11.17, 12.25, 13.05, 13.70, 14.47, 15.46, 16.60, 18.17, 21.39, 23.51, 28.14. 70 60 Yield (%) 50 40 30 20 10 0 0 20 40 60 80 100 120 Time (minutes) Figure 3: Knoevenagel condensation of benzaldehyde and ethyl acetoacetate in DMSO at 353 K catalysed by IRMOF-3 (♦), aniline (■) and no catalyst (blank, ▲); n = 3 repeats. 140 60 50 Yield (%) 40 30 20 10 0 0 20 40 60 80 100 120 140 Time (minutes) Figure 4: Knoevenagel condensation of benzaldehyde and ethyl acetoacetate in DMF at 353 (■); 333 (▲) or 313(♦) K) catalysed by IRMOF-3; n = 3. 60 50 Yield (%) 40 30 20 10 0 0 20 40 60 80 100 120 Time (minutes) Figure 5: Knoevenagel condensation of benzaldehyde and ethyl acetoacetate in MeOH (▲) and EtOH (○) at 333 K catalysed by IRMOF-3; n = 3 repeats. 140 35 30 Yield (%) 25 20 15 10 5 0 0 20 40 60 80 100 120 140 Time (minutes) Figure 6: Knoevenagel condensation of benzaldehyde and ethyl acetoacetate in DMF at 313 K catalysed by IRMOF-3. Benzaldehyde (■) added first; ethyl acetoacetate (♦) added first; n = 3. Statistical analysis An ANalysis Of VAriance (ANOVA) was performed between groups of the final conversions of each catalytic run at 130 minutes to statistically investigate the likelihood of such a result occurring for the heterogenous vs. homogenous, solvent and temperature studies. This statistical analysis was selected over a Student’s t-test, for these analyses, as only the variation between two groups can be compared at a time and with multiple sets of data needing to be compared (heterogenous vs. homogenous – 3, solvent analysis – 5, temperature – 3) there are a large number of resulting pairs to be compared against each other. The 5 solvent triplicate results would generate 9 pairs of data to be compared. In so many pairings we should not be surprised to observe things that happen only 5 % of the time and thus P = 0.05 cannot be considered significant. ANOVA compiles all that data into a single number, the F ratio, which is the found variation of the group averages to the expected variation of the group averages and a single probability, P, for Ho, the null hypothesis. Thus the F ratio is the ratio between the variation of the experimental treatment and the variation due to experimental error. 𝐹= ̅𝑖 − 𝑌̅)2 ⁄(𝐾 − 1) ∑𝑖 𝑛𝑖 (𝑌 found variation = ̅𝑖 )2 ⁄ (𝑁 − 𝐾) expected variation ∑𝑖𝑗 (𝑌𝑖𝑗 − 𝑌 ̅𝑖 is the sample mean within the ith group which has ni observations and 𝑌̅ is the overall mean for the data where 𝑌 and Yij is the jth observation within the ith out of K groups in a sample size of N If the F ratio is equal to 1 then the treatment effect is the same as the experimental error and the experimental treatment actually does not affect the outcome of the conversion in the catalytic cycle and the null hypothesis is accepted. The null hypothesis states that there is no real effect in the conversion, of benzaldehyde and ethyl acetoacetate or ethyl cyanoacetate in the Knoevenagel condensation, when the statistically analysed variable such as temperature or solvent is changed. The null hypothesis can be rejected when the F ratio is significantly larger than 1, such that the probability of it equalling 1 is less than 5 % as P < 0.05. Besides the much larger conversion ability and larger kobs that IRMOF-3 has as compared to aniline or when no catalyst is present the ANOVA F ratio, Table 1, was 237.4 which is significantly larger than 1, indicating a large effect due to the presence of the IRMOF-3 catalyst, with P < 0.0001 thus Ho is rejected allowing the alternative hypothesis to be accepted, which is that IRMOF-3 catalyses the Knoevenagel condensation of benzaldehyde and acetoacetate. The effect of choice of solvent was studied and the reliability of the differences in conversion of the substrate over the range of solvents was studied using ANOVA. The choice of solvent, in promoting high reaction conversion, was shown to be significant and have a large effect as F = 91.53, with P < 0.0001 thus Ho is rejected allowing the alternative hypothesis to be accepted, which is that solvent choice is significant to determine the reaction conversion in the Knoevenagel condensation of benzaldehyde and acetoacetate. The conversions obtained when varying the temperature were also statistically analysed revealing that F = 79.00 and that temperature is also significant in determining the conversion of substrate, with P < 0.0001 thus Ho is rejected allowing the alternative hypothesis to be accepted, which is that temperature is significant to determine the reaction conversion in the Knoevenagel condensation of benzaldehyde and acetoacetate. Table 1: ANOVA results for heterogenous vs. Homogenous, solvent and temperature studies Mean Median reaction reaction 95 % Confidence Standard conversion conversion Interval deviation (%) (%) IRMOF-3 64.533 64.60 60.30; 68.77 4.40 Aniline 27.633 29.40 22.78; 32.49 3.59 Blank 3.9000 4.20 -0.9530; 8.753 1.77 DMSO 64.533 64.60 60.30; 68.77 4.40 DMF 54.000 54.00 49.76; 58.24 0.500 MeOH 43.000 46.00 38.76; 47.24 5.20 EtOH 42.267 42.00 38.03; 46.50 1.42 Toluene 15.767 16.00 11.53; 20.00 2.36 353 K 54.000 54.00 50.32; 57.68 0.00 333 K 36.472 36.23 32.79; 40.15 1.42 313 K 27.733 26.50 24.05; 31.42 4.29 Factors compared Heterogenous vs Homogenous Solvent Temperature F ratio P 237.4 <0.0001 91.53 <0.0001 79.00 <0.0001 The Student’s t-test was selected as a statistical tool to investigate into the reliability of the differences within the catalysed conversion of benzaldehyde and ethyl acetoacetate or ethyl cyanoacetate. In this test, developed by Student (W. S. Gossett) for small data sets where few samples are taken, the calculated mean and standard deviation might per chance deviate from the true mean and standard deviation. If the differences between the two measured samples are large enough the null hypothesis, that the differences are in fact due to chance, should be rejected. This occurs if P < 0.05. As mentioned before the catalytic Knoevenagel condensation of benzaldehyde and ethyl acetoacetate at 353 K in MeOH and EtOH gave what appeared to be similar results and the reaction was rerun at 333 K, which was below their respective boiling points. A Student’s t-test on the conversion results of MeOH and EtOH at 353 K proved that null hypothesis cannot be rejected as P = 0.825 and therefore must be accepted, thus the small differences between the conversion and thus kobs and TOFs can be ignored, and that there is no significant difference in the reaction conversion at 353 K between these two solvents. However, at 333 K significance was seen between MeOH and EtOH in the catalytic conversion of benzaldehyde and acetoacetate as P = 0.003 and the Ho must be rejected as the difference between the conversions of MeOH and EtOH are not by chance and the conversion obtained is governed by the solvent chosen. The order of addition of substrate into the reaction mixture was shown to be negligible by the statistical analysis of the conversion when adding either benzaldehyde or ethyl acetoacetate first as P = 0.966. This high probability is explained by the near exact replication of the conversion of substrate when adding either substrate first into the reaction mixture. Table 2: Student t-test results for solvent, order of addition and substrate studies Mean Factors compared yield (%) Median yield (%) 95 % Confidence Interval Standard deviation Solvents MeOH 43.0 46.0 36.90; 49.10 5.20 (353 K) EtOH 42.3 42.0 36.16; 48.37 1.42 Solvents MeOH 53.5 52.8 47.84; 59.23 2.19 (333 K) EtOH 34.7 36.6 28.97; 40.36 4.52 Order of Benzaldehyde 27.6 26.4 21.80; 33.40 2.80 substrate Ethyl addition acetoacetate 27.7 26.5 21.93; 33.53 4.29 IRMOF-3 27.7 26.5 22.32; 33.15 4.29 MIXMOF 30.0 30.6 24.62; 35.45 2.11 IRMOF-3 27.7 26.5 21.52; 33.95 4.29 44.0 45.2 37.75; 50.18 3.42 IRMOF-3 62.3 62.5 58.19; 66.34 1.66 MIXMOF 62.9 63.5 58.86; 67.01 3.19 IRMOF-3 62.3 62.5 59.62; 64.92 1.66 73.1 72.5 70.48; 75.78 1.64 Ethyl aceto acetate substrate UMCM-1-NH2 Ethyl cyano acetate substrate UMCM-1-NH2 t value Standard P deviation 0.236 3.81 0.825 -6.50 3.55 0.003 0.0451 3.62 0.966 -0.834 3.38 0.451 -5.13 3.88 0.007 -0.321 2.54 0.764 -8.05 1.65 0.001 In both cases of comparing IRMOF-3 and MIXMOF when catalysing the Knoevenagel condensation between benzaldehyde and ethyl acetoacetate or ethyl cyanoacetate P = 0.451 and P = 0.764 respectively. These significant probabilities indicate that the conversions obtained are significantly the same and their slight disparities are random. Lastly, the catalytic conversions of benzaldehyde and ethyl acetoacetate or ethyl cyanoacetate when using UMCM-1-NH2 and IRMOF-3 were analysed using the Student’s t-test to compare their performance and abilities relative to one another. In both compared cases, P < 0.05 outlining that UMCM-1-NH2 has a higher ability than IRMOF-3 to catalyse the reaction and specifically of that between benzaldehyde and ethyl cyanoacetate as P = 0.0001, which is less than P = 0.007 for that of the benzaldehyde and ethyl acetoacetate.