THE MINERALOGICAL FATE OF ARSENIC DURING WEATHERING OF

SULFIDES IN GOLD-QUARTZ VEINS: A MICROBEAM ANALYTICAL STUDY

A Thesis

Presented to the faculty of the Department of Geology

California State University, Sacramento

Submitted in partial satisfaction of

the requirements for the degree of

MASTER OF SCIENCE

in

Geology

by

Tamsen Leigh Burlak

SPRING

2012

© 2012

Tamsen Leigh Burlak

ALL RIGHTS RESERVED

ii

THE MINERALOGICAL FATE OF ARSENIC DURING WEATHERING OF

SULFIDES IN GOLD-QUARTZ VEINS: A MICROBEAM ANALYTICAL STUDY

A Thesis

by

Tamsen Leigh Burlak

Approved by:

__________________________________, Committee Chair

Dr. Charles Alpers

__________________________________, Second Reader

Dr. Lisa Hammersley

__________________________________, Third Reader

Dr. Dave Evans

____________________________

Date

iii

Student: Tamsen Leigh Burlak

I certify that this student has met the requirements for format contained in the University

format manual, and that this thesis is suitable for shelving in the Library and credit is to

be awarded for the project.

_______________________, Graduate Coordinator

Dr. Dave Evans

Department of Geology

iv

___________________

Date

Abstract

of

THE MINERALOGICAL FATE OF ARSENIC DURING WEATHERING OF

SULFIDES IN GOLD-QUARTZ VEINS: A MICROBEAM ANALYTICAL STUDY

by

Tamsen Leigh Burlak

Mine waste piles within the historic gold mining site, Empire Mine State Historic

Park (EMSHP) in Grass Valley, California, contain various amounts of arsenic and are

the current subject of remedial investigations to characterize the arsenic present. In this

study, electron microprobe, QEMSCAN (Quantitative Evaluation of Minerals by

SCANning electron microscopy), and X-ray absorption spectroscopy (XAS) were used

collectively to locate and identify the mineralogical composition of primary and

secondary arsenic-bearing minerals at EMSHP. Primary arsenic-bearing minerals

identified include the following sulfoarsenides: arsenian pyrite (Fe(S,As)2), arsenopyrite

(FeAsS), and cobaltite ((Co,Fe)AsS). Subaerial weathering of these primary sulfoarsenide

minerals within mine waste piles has led to oxidation of As(-I) to As(V), allowing for the

formation of several arsenic-bearing secondary minerals including the hydrous ferric

v

oxides (HFO) ferrihydrite (5Fe2O3•9H2O) and goethite (FeOOH), scorodite

(FeAsO4•2H2O), and various other hydrous ferric arsenates (HFA) and Ca-Fe arsenates.

Some of the secondary oxide and arsenate minerals contained more arsenic on a weight

basis than the primary sulfide minerals, up to a maximum of 48.1 wt. % arsenic compared

to a maximum 44.8 wt. % arsenic in primary minerals. This trend of higher

concentrations of arsenic in the secondary minerals than in the primary minerals may be

caused by multiple factors, including preferential weathering of arsenic-rich regions in

zoned arsenian pyrite, weathering of higher arsenic arsenopyrite, and incorporation of

arsenate in HFO and HFA by adsorption or coprecipitation. According to other studies,

secondary minerals such as arsenic-bearing Fe-oxides and Ca-Fe arsenates are more

soluble in the human gut than the primary As-bearing sulfide minerals, leading to higher

bioaccessibility and bioavailability. Results from studies conducted in this thesis may

have implications for improving the understanding of arsenic bioaccessibility of mine

waste within the EMSHP, and possibly at other historic gold mine sites in California and

elsewhere that have similar mine waste undergoing subaerial weathering involving

oxidation of arsenic-bearing primary sulfoarsenide minerals and formation of secondary

oxide and arsenate minerals.

_____________________, Committee Chair

Dr. Charles Alpers

______________________

Date

vi

FOREWARD

This thesis is part of a multi-disciplinary investigation into arsenic bioavailability

in mine waste focused on the Empire Mine State Historic Park (EMSHP) in Grass Valley,

California. The purpose of the overall investigation is to better understand the nature and

chemical speciation of arsenic in mine waste and at what level exposure to it becomes a

concern to human health. Funding for the overall investigation was provided to the

California Department of Toxic Substances Control (DTSC) through a Brownfields

Training, Research, and Technical Assistance Grant from the U.S. Environmental

Protection Agency. A goal of the investigation for DTSC is to develop an assessment tool

that would allow the prediction of arsenic bioavailability in soil samples from mine sites

in a sound, defensible, and cost-efficient manner (California DTSC, 2010).

DTSC initiated a partnership involving several other institutions to carry out the

multi-disciplinary studies of bioavailability and bioaccessibility of arsenic in mine waste.

The partners in this research include Prof. Nicholas Basta (The Ohio State University)

who is doing bioaccessibility studies with simulated gastric and intestinal fluids (in vitro

testing), Prof. Stan Casteel (University of Missouri) who is doing bioavailability studies

using juvenile swine (in vivo testing), Prof. Christopher Kim (Chapman University) who

is analyzing the concentration of arsenic and other metals in various grain-size fractions,

Dr. Andrea Foster (U.S. Geological Survey, USGS) who is analyzing the speciation of

iron and arsenic in mine waste samples using X-ray absorption spectroscopy (XAS) with

vii

synchrotron radiation, and Dr. Alex Blum (USGS), who is characterizing soil and rock

samples using powder x-ray diffraction (XRD).

The work in this thesis is focused on characterizing the mineralogy and

geochemistry of primary and secondary (weathering) minerals from mine waste piles at

the EMSHP. The thesis is designed to complement the work being done by others on the

multi-disciplinary research team with the goal of improving the understanding of

mineralogy and chemical speciation and their relation to arsenic bioavailability and

bioaccessibility.

viii

DEDICATION

I lovingly dedicate this thesis to my family and future husband, who together

supported me each step of the way.

ix

ACKNOWLEDGEMENTS

I am grateful to my primary advisor, Charles Alpers, whose guidance and support

from the beginning to the end enabled me to appreciate this thesis project and to develop

a more comprehensive understanding of the subject. I am also grateful to Lisa

Hammersley and Dave Evans, whose encouragement, editing assistance, and support

allowed me to stay on course during this process. I offer my regards to Andrea Foster

who provided assistance with XAS, Sarah Roeske and Nick Botto who provided

assistance on the electron microprobe, and Erich Petersen who provided assistance on

QEMSCAN. I would also like to thank DTSC and Holdrege and Kull for assistance in

sample collection, and the USEPA and USGS for funding.

In addition, I would like to show my gratitude to my future husband, Andrew

Regnier, and my close friend, Maia Kostlan, for providing your love and undying support

in a number of ways through the writing process.

Lastly, I offer my regards to all of those not mentioned who supported me in any

respect during the completion of this thesis.

x

TABLE OF CONTENTS

Page

Foreward ........................................................................................................................... vii

Dedication .......................................................................................................................... ix

Acknowledgements ............................................................................................................. x

List of Tables ................................................................................................................... xiii

List of Figures .................................................................................................................. xiv

Chapter

1. INTRODUCTION .......................................................................................................... 1

Geologic Setting...................................................................................................... 5

Units and Rock Types Present .................................................................... 6

2. METHODS ..................................................................................................................... 8

Reconnaisance Sampling ........................................................................................ 9

Trench Sampling ..................................................................................................... 9

X-Ray Absorption Spectroscopy using Synchrotron Radiation ........................... 12

Beamline 10-2 ........................................................................................... 12

Beamline 2-3 ............................................................................................. 13

QEMSCAN ........................................................................................................... 14

Electron Microprobe ............................................................................................. 14

Methods Summary ................................................................................................ 20

3. RESULTS ..................................................................................................................... 21

Sulfide Composition from Electron Microprobe Analysis ................................... 21

Oxide Composition from Electron Microprobe Analysis ..................................... 29

Comparison of Sulfide and Oxide Compositions ................................................. 34

4. DISCUSSION ............................................................................................................... 52

Sulfide Minerals .................................................................................................... 52

Hydrous Ferric Oxide (HFO) ................................................................................ 55

xi

Hydrous Ferric Arsenate (HFA) ........................................................................... 59

5. CONCLUSIONS........................................................................................................... 61

Appendix A. Standard Operating Procedure for XAS Element Map Processing and PCA

Analysis............................................................................................................................. 64

Appendix B. Electron Microprobe Sulfide Analyses (Wt. %).......................................... 70

Appendix C. Electron Microprobe Oxide Analyses (Wt. %) ........................................... 97

References ....................................................................................................................... 138

xii

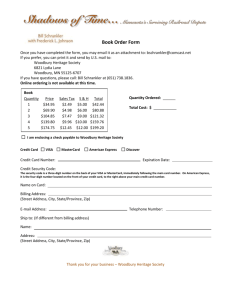

LIST OF TABLES

Tables

Page

1.

Table 1 List of Arsenic-Bearing Minerals in Empire Mine Waste Rock ........... 4

2.

Table 2 Element Detection Limits: Oxides (Wt. %) … ..................................... 16

3.

Table 3 Element Detection Limits: Sulfides (Wt. %) ....................................... 17

4.

Table 4 Electron Microprobe Standards ........................................................... 18

5.

Table 5 Summary of Sulfide Composition Data for All Sites .......................... 23

6.

Table 6 Unknown Ca-Fe Arsenates .................................................................. 30

7.

Table 7 Summary of Oxide Composition Data for All Sites ............................ 31

xiii

LIST OF FIGURES

Figures

1.

Page

Figure 1 Location map and geologic map of Grass Valley, California (modified

from Ernst et al., 2008 and Mayfield et al., 2000) ............................................ 7

2.

Figure 2 Location map for nine sites sampled at EMSHP .............................. 11

3.

Figure 3 Box plot for the arsenic concentrations in primary and secondary

minerals at EMSHP analyzed by electron microprobe ................................... 22

4.

Figure 4 Cumulative distribution of arsenic concentrations of arsenian pyrite

grains across all sites sampled ......................................................................... 24

5.

Figure 5 Box plot for the arsenic concentrations in primary and secondary

minerals at EMSHP analyzed by electron microprobe ................................... 25

6.

Figure 6 Low- (<0.15 wt. %), medium- (0.15 – 1 wt. %), and high- (>1 wt. %)

arsenic pyrite and hydrous ferric oxide (HFO) across all sites ....................... 26

7.

Figure 7 Low- (<0.15 wt. %), medium- (0.15 – 1 wt. %), and high- (>1 wt. %)

arsenic pyrite and HFO plotted by site ............................................................ 27

8.

Figure 8 Distribution of low, medium, and high arsenic pyrite and HFO across

all sites ............................................................................................................. 28

9.

Figure 9 Cumulative distribution of arsenic concentration in HFO and

pyrite ................................................................................................................ 32

10.

Figure 10 Box plot showing the arsenic concentrations in pyrite and HFO at

EMSHP analyzed by electron microprobe ...................................................... 37

xiv

11.

Figure 11 Analyzed electron microprobe variation of As2O5 versus Fe2O3 .... 38

12.

Figure 12 Analyzed electron microprobe variation of CaO versus As2O5 ...... 40

13.

Figure 13 Ternary diagrams showing electron microprobe components in

weight percent ................................................................................................. 42

14.

Figure 14 Unknown Ca-Fe arsenates from Power Line Central and Power Line

East sites .......................................................................................................... 46

15.

Figure 15 Molar bidirectional plots for pyrite/HFO and arsenopyrite/HFA with

grain textures ................................................................................................... 47

16.

Figure 16 Weight percent bidirectional plots for pyrite/HFO and

arsenopyrite/HFA with grain textures ............................................................. 49

17.

Figure 17 QEMSCAN and XAS images from a Prescott Shaft thin section .. 50

18.

Figure 18 Backscatter electron images of zoned arsenian pyrite from two

EMSHP localities ............................................................................................ 53

19.

Figure 19 QEMSCAN image illustrating the presence of pyrite/HFO and

arsenopyrite/HFA at EMSHP .......................................................................... 57

xv

1

Chapter 1

INTRODUCTION

Arsenic was first recognized as an element around 1250 CE (Vaughan, 2006), and

since then arsenic has been acknowledged both as a poison and for its pharmaceutical

benefits (Mead, 2005; Vaughan 2006). Long-term effects of arsenic exposure may

include: internal and external cancers, diabetes, and adverse effects on reproductive,

developmental, and neurological health. Short-term effects may include: abdominal pain,

vomiting, muscle weakness, swelling, and motor/sensory deterioration (WHO, 2001;

Frankenberger, 2002; Mead, 2005; Vaughan, 2006). The most toxic forms of arsenic are

inorganic and include (in order of decreasing toxicity) the gas arsine (AsH3), arsenite

(AsO3-3), and arsenate (AsO4-3) (Vaughan, 2006; Meunier et al., 2010). Organic arsenic

compounds are generally less toxic than inorganic forms, although details of toxicity to

humans of organic arsenic compounds are unknown (Vaughan, 2006). Arsenic has been

extensively studied as a drinking water contaminant in third world countries due to the

negative effects of long-term exposure to low dosages (WHO, 2001; Frankenberger,

2002; Mead, 2005; Vaughan, 2006). More direct routes of arsenic exposure include

ingestion in food (WHO, 2001; Vaughan, 2006; Guilbert-Diamond et al., 2011; Jackson

et al., 2012) inhalation of As from airborne particles (Reeder et al., 2006; Walker et al.,

2009), and ingestion of As by drinking water (Welch et al., 2000; Ayotte et al., 2003).

Arsenic contamination has been linked to gold mining (Mead, 2005; Obiri, 2006;

Vaughan, 2006; Morey et. al., 2008; Haffert, 2010) because of the close geochemical

association of As-bearing minerals such as arsenopyrite (FeAsS) and arsenian pyrite

2

(Fe,(S,As)2) (Table 1) with gold (Mead, 2005; Obiri, 2006; Haffert, 2010;). Arsenopyrite

and arsenian pyrite within waste rock piles from gold mining have a tendency to release

arsenic into the surrounding environment by the oxidation of As-bearing primary

minerals (Welch et al., 2000; Lazareva et al., 2002; Morin et al., 2002; Black et al., 2004;

Walker et al., 2009). Once released to the environment, arsenic can create potential

environmental and bioavailability hazards for residential and commercial development of

land on and adjacent to historic mine sites (Lazareva et al., 2002; Meunier et al., 2010).

In mining-impacted areas such as the Sierra Nevada, specific exposure routes for arsenic

can include: inhalation or ingestion of mine waste particles from dust, uptake into

agricultural produce from irrigation water (Ayotte et al., 2011), dermal absorption of

arsenic in former tailings ponds now used for recreational swimming or boating, and

eating fish found in historic tailing retention ponds (Ashley et al., 1999; Foster et al.,

2011).

Two gold mine sites in California with known arsenic contamination include Lava

Cap in Nevada City, CA and the Mesa del Oro tailings from the Central Eureka mine in

Sutter Creek, CA. Lava Cap experienced a tailings dam failure in the winter of 1996 that

released unoxidized, arsenic-rich, fine-grained mill tailings into the local creek and lake

(Ashley et al., 1999; Foster et al., 2011). The unoxidized arsenopyrite and arsenian pyrite

were introduced to the water and these sulfoarsenides oxidized to form As-bearing

secondary phases such as scorodite (FeAsO4•2H2O) (Table 1). Interaction of the

secondary phases with water allowed for sorption and/or coprecipitation of arsenic onto

Fe-oxyhydroxides, increasing the arsenic concentration of the lake thirty-fold (Ashley et

3

al., 1999; Foster et al., 2011). The Mesa del Oro subdivision in Sutter Creek, CA contains

both residential and recreational sites built on an 11-acre pile of tailings where it was

estimated that 25% of the arsenic was soluble and arsenic levels were 50 or more times

above the maximum allowed contaminant level (22 parts per million) (Greenwald, 1995).

Although chronic exposure to arsenic has been linked to cancer and kidney disease, the

health problems associated with As-rich mine tailings and waste rock are largely

unknown (Greenwald, 1995).

The goal of this master’s thesis project was to characterize the mineralogical

sources and sinks of inorganic arsenic (As) in mine waste materials. Specific objectives

were (1) to characterize the mineralogy and geochemistry of As in primary, iron- (Fe)bearing sulfoarsenide minerals in waste rock at several historical mines within the park,

and (2), to trace the fate of As and Fe in secondary weathering products including Feoxides, Fe-arsenates, and related minerals. Other weathering products such as Ca-Fe

arsenates are of particular interest because they have higher arsenic bioaccessibility than

Fe-oxides (Paktunc et al., 2004; Walker et al., 2009; Meunier et al., 2010). By collecting

data from samples taken from piles of mine waste distributed throughout the EMHSP, the

spatial distribution of arsenic in arsenian pyrite and associated oxide and arsenate

weathering products were assessed. This work was done concurrently with broader

investigations being conducted at the Empire Mine State Historic Park by DTSC, the

United States Geological Survey (USGS), and others (see Foreward).

4

Table 1

List of Arsenic-Bearing Minerals in Empire Mine Waste Rock

Table 1 List of minerals confirmed by electron microprobe analyses to be present in mine

waste piles at Empire Mine State Historic Park. Mineral formulas are for end members

(pure phases).

5

GEOLOGIC SETTING

The Empire Mine State Historic Park (EMSHP) in Grass Valley is located on the

western sloping foothills of the Sierra Nevada within the northern Mother Lode gold belt

in California (Figure 1). The Mother Lode consists of gold-bearing quartz veins (Clark,

1970; Böhlke et al., 1986) and mineralized schist and greenstone that stretch 150 miles

from the town of Mariposa to northern Sierra County and that have produced millions of

troy ounces of gold (Clark, 1970). The Mother Lode was emplaced during the Cordilleran

orogen and resides within a series of accreted terranes that have long been actively

deformed since their respective docking with the Pacific margin of the United States

(McCuaig et al., 1998). Volcanic arcs and accreted terranes were deposited on the Pacific

margin from the Early Triassic through the Late Jurassic, with a magmatic arc developing

in the Late Jurassic (Goldfarb et al., 1998). From 155 to 123 Ma, deformation and

metamorphism occurred, followed by emplacement of plutons and the Sierra Nevada

batholith from 151 to 80 Ma (Goldfarb et al., 1998). The Mother Lode resides within

these terranes and is associated with steeply-dipping thrust faults (Tuminas, 1983; Ernst

et al., 2008) where extensive gold mineralization took place during 150 to 50 Ma

(Goldfarb et al., 1998; Robb, 2005). CO2-rich fluids rising up from processes resulting

from subduction were injected into major fracture zones within the metamorphic

accretion complex (Johnston 1940; Böhlke 1989). The Melones Fault Zone and Wolf

Creek Fault Zone near Grass Valley (Figure 1) (Tuminas 1983; Mayfield et al., 2000)

allowed silica and other felsic components to leach from the crust, as 230º to 370º C

fluids (Böhlke et al., 1986) rich in CO2 migrated upward into the fractures. At this point

6

fractures filled with several generations of quartz, calcite, various sulfides, and gold

(Knaebel 1931; Johnston 1940; Böhlke 1989; Goldfarb et al, 1998).

UNITS AND ROCK TYPES PRESENT

Grass Valley lies within a Cretaceous age (127 Ma) granodiorite pluton (Böhlke

et al., 1986) bordered by Jura-Triassic-age arc serpentinite and ophiolite, Upper Jurassic

accretionary sequence volcanics, slate, and greenschist, and Carboniferous to Triassic-age

Calaveras Complex chert and fine grained argillite (Figure 1) (Knaebel, 1931; Johnston,

1940; Mayfield et al., 2000; Ernst et al., 2008). The Calaveras Complex, Jura-Triassic

arc, and the Upper Jurassic accretionary sequence are part of the Western Metamorphic

Belt (Ernst et al., 2008). This belt was deformed and metamorphosed during the Nevadan

orogeny (Ernst et al., 2008), and is intruded by granite and other igneous rocks (Mayfield

et al., 2000). Other common igneous and metamorphic rocks in the area include:

amphibolite, schist, serpentine, gabbro, diorite, quartz porphyry, carbonates, calcite,

dolomite, and several dike intrusions of various compositions (Knaebel, 1931; Johnston,

1940). Rock names were confirmed by bulk XRD performed on fresh rock samples

collected at EMSHP (A. Blum, written communication, 2012).

7

Figure 1 Location map and geologic map of Grass Valley, California (modified from

Ernst et al., 2008 and Mayfield et al., 2000). Grass Valley is located in a 127 million year

old granitic pluton (Böhlke et al., 1986) within the Western Metamorphic Belt. The

Western Metamorphic Belt units adjacent to Grass Valley include the Calaveras

Complex, Jura-Triassic arc, and the Upper Jurassic accretionary sequence (Mayfield et

al., 2000; Ernst et al., 2008). BMF – Bear Mountain fault; CFST – Calaveras-Shoo Fly

thrust; DF – Downieville fault; GHF – Gillis Hills fault; GM – Grizzly Mountain thrust;

HCW – Higgins Corner window; MF – Melones fault; SPF – Spencerville fault; TT –

Taylorsville Thrust; UF1 – unnamed Fault 1; WCF – Wolf Creek fault (Ernst et al.,

2008).

8

Chapter 2

METHODS

Nine mine waste piles were sampled within EMSHP, with some collection sites

located under dense vegetation. EMSHP is the site for more than one arsenic

investigation, including an investigation at the Magenta Drainage Tunnel by the

California Regional Water Quality Control Board – Central Valley Region (Myers, 2006;

MFG, 2006; Vestra, 2009) and a bioavailability/bioaccessibility investigation being

conducted by the California Department of Toxic Substances Control (DTSC) (MFG,

2006; MFG, 2009; Tetra, 2010). During the sample collection for this thesis project,

DTSC scientists were simultaneously collecting field data using a field X-ray

fluorescence (XRF) spectrometer, digging shallow trenches (to a maximum depth of 4

feet) with a backhoe in the mine waste piles, and collecting soil samples from the mine

waste piles. DTSC’s field XRF results showed the waste piles had variable levels of

arsenic from less than one hundred ppm to several thousand ppm during the initial

reconnaissance trip, so precautions were taken during the main sampling event to

minimize inhalation and ingestion of arsenic. Precautions included use of a water truck to

control dust, preventing exposure to airborne arsenic while digging trenches, and

thorough washing of all equipment and hands. Trenches dug by a contractor under the

supervision of DTSC permitted the collection of hard rock specimen for this thesis

project from inside the mine waste piles down to a depth of four feet. The goal of the

hard rock sampling was to represent the available variety of primary sulfide

9

mineralization and weathering products. All hard rock samples were placed in plastic

bags labeled by site, date, and visible composition.

RECONNAISANCE SAMPLING

During April, 2009, several hand samples of rock were collected in proximity to

the mine waste piles identified by DTSC as points of interest using field XRF. Sulfiderich rock samples, both weathered and unweathered, were collected along the Power Line

Trail (Figure 2) in addition to samples of granodiorite and diorite/diabase to aid in

characterization of the host rock. The sulfide minerals that were targeted in the collection

of hand specimens, including arsenopyrite and arsenian pyrite (Table 1), have known

associations with arsenic.

TRENCH SAMPLING

During September, 2009, a backhoe operated by a DTSC-hired private contractor

was used to dig trenches to facilitate bulk sample collection for mine-waste

characterization at 21 locations within the EMSHP and 4 locations on nearby private

land. Park rangers and historians supervised sample collection to ensure the historical

items present within the park were not disturbed by the trenching operation. Trenches at

each waste dump were no deeper than 4 feet and were refilled immediately after samples

were taken. Rock samples were collected from within the trenches and in proximity to the

trenches. A total of 14 trenches (Trenches 1-14) were sampled within the state park

borders. Four additional trenches (Trenches 15-18) were sampled in Rattlesnake Gates, a

residential area adjacent to EMSHP. Within the EMSHP, the mine waste piles sampled

for this project included: Betsy Mine, Empire Mine Dump, Power Line Central, Power

10

Line East, Prescott Dump, Prescott Shaft Area, Sebastopol, Woodbury North, and

Woodbury South (Figure 2). Samples were collected, placed in Ziploc® bags, labeled

with the site and date, and transported in five gallon buckets. Suspected high arsenic and

low arsenic samples were kept in separate bags to minimize cross-contamination. All

equipment used for collection was washed thoroughly with water after each sample was

collected to minimize potential for cross-contamination.

Rock chips were cut from hand samples using a diamond-tipped rock saw, and

were then sent off for thin sectioning by a commercial lab, Spectrum Petrographics, Inc.

(Vancouver, Washington). All sections were created to the following specifications:

mounting on 27 x 46 mm glass slides, a 30 or 60 micrometer (μm) thickness of each

sample, and an ethyl cyanoacrylate (Instant Krazy Glue®) mounting medium to allow for

possible future removal from glass slides for additional analysis not performed in this

thesis project. All sections were left uncovered, were doubly polished for microprobe

work, had EPOTEK 301 embedding, and were treated as heat and water sensitive because

of the hydrous and possibly soluble nature of some minerals present (e.g. hydrous ferric

arsenate minerals such as scorodite and Ca-Fe-arsenates).

11

Figure 2 Location map for nine sites sampled at EMSHP. The location of the Power Line

Trail sampled during reconnaissance is shown (modified from MFG, 2009). The eight

sampling sites were chosen for their wide range in arsenic content based on field XRF,

and trenches were dug by a contractor down to a maximum 4 feet, facilitating hand

sample collection from each mine waste pile.

12

X-RAY ABSORPTION SPECTROSCOPY USING SYNCHROTRON RADIATION

Two different beamlines at the Stanford Synchrotron Radiation Lightsource

(SSRL) facility in Menlo Park, CA were utilized for spectroscopic analysis. Beamline 102 was used initially to collect data on X-ray absorption spectroscopy (XAS), XAS

imaging, and X-ray scattering. This beamline has an energy range of 4,500-30,000

electron-volts (eV) and a spot size ranging from about 0.2 x 0.43 millimeters (mm) to 2.0

x 20 mm. Subsequently, Beamline 2-3 was used to collect higher-resolution XAS

imaging with a finer beam size. This beamline has an energy range of 4,500-24,000 eV

and a 2 x 2 µm spot size. A disadvantage to using Beamline 2-3 was an increased scan

time because of the finer beam spot size (SLAC, 2012). Element maps and point counts

were collected from the polished thin sections at both beamlines. Additional details on

both beamlines are provided below.

BEAMLINE 10-2

Arsenic and iron redox maps of thin sections were created for some full thin

sections. Redox speciation analysis is important for differentiating oxidation states of

elements by comparing the total element concentration and the lowest concentration state,

allowing for the determination of potential toxicity. Using the element maps, regions of

interest (ROIs) were selected for more refined analysis on Beamline 10-2, specifically

more detailed maps of portions of the thin sections with sulfide minerals and their

weathering products. The following elements were targeted due to their general

association with hydrothermal gold deposits: As, Ca, Cu, Fe, K, Ni, Mn, and Zn. Using

known excitation energies for these elements, energy levels were chosen that would

13

excite certain valences of arsenic and iron (for the redox maps) in addition to exciting the

other chosen elements. Element distributions mapped for As-redox included the energies

11,871, 11,882, 11,886, 12,000, and 13,000 eV to capture the peak valence energies for

As(-I), As(III), and As(V). Element distributions mapped for Fe-redox included the

energies 7,122, 7,133, 7,137, and 7,500 eV to capture the peak valence energies for Fe(II)

and Fe(III). The beam was set to record at the 100-µm pixel size for the entire run

because this was the first time looking at the samples in this way and time constraints

prevented use of a finer beam size. Raw data collected using Beamline 10-2 were stored

in the SSRL database, and were manipulated using the SMATK (Sam’s Microprobe

Analysis Kit) program written by United States Geological Survey (USGS) /SSRL

employee, Sam Webb. SMATK was used to deadtime-correct and manipulate the data

collected from the Beamline 10-2. From this program, element maps, element vs. element

correlation plots, and speciation tri-color plots were created to represent the data.

BEAMLINE 2-3

The higher spatial resolution of Beamline 2-3 allowed for the collection of microscale X-ray fluorescence (micro-XRF) and extended X-ray absorption fine structure

(EXAFS) spectra. A 2-µm pixel size was used for mapping with this beamline, focusing

mainly on arsenic valence states As(III) and As(V). Specific energies for arsenic that

were collected included: 11,868 eV, 11,870 eV, 11,873 eV, 11,876 eV, and 11,890 eV.

These energies were chosen to capture the arsenic peaks for different valences (As(-I),

As(III) and As(V)). Principal component analysis (PCA) was performed on the microXRF data using the SMATK program after all the collected energy channels for arsenic

14

were deadtime corrected and a composite file of data from all channels was created.

Composite files were created using a standard operating procedure outlined by

USGS/SSRL scientist Andrea Foster for this project (Appendix A). From these corrected

composite files, element vs. element correlation plots were created and masks of

observed linear trends were applied to the element maps.

QEMSCAN

Studies using QEMSCAN (Quantitative Evaluation of Minerals by SCANning

electron microscopy) were conducted at the University of Utah in Salt Lake City, Utah.

Carbon coating provided a conducting surface to prevent buildup of negative charge on

the surface of the sample. Mineral maps were created by scanning thin sections at the 2.5µm pixel scale, concentrating on areas with primary sulfide and secondary oxide

mineralization. A proprietary software suite, iDiscover, was used to store and manipulate

the data collected during these scans. Backscattered electron (BSE) images (greyscale)

were collected to illustrate mineral textures. False-color mineral maps were created from

spectra collected from electron-induced x-ray emission using a spectral library to yield

mineral names. The mineral maps show the spatial relationships between unweathered

primary sulfides, weathered As-rich and As-poor sulfides, and their respective As-rich

and As-poor iron oxide weathering products.

ELECTRON MICROPROBE

The UC Davis Cameca SX-100 Microprobe was used to obtain quantitative

information on mineral chemistry using the same thin sections analyzed by other methods

(Appendix B, C). The work focused on samples that showed the most arsenic- and iron-

15

bearing primary and secondary minerals. A focused 3-µm electron beam with a current of

4 nanoamperes (nA) at 15 kilovolts (kV) was used for oxides, and a 1-µm electron beam

with a current of 20 nA at 15 kV was used for sulfides. Beam diameters caused excitation

of the sample under the polished surface to a depth of approximately10 µm. The oxide

beam set at a beam current of 4 nA permitted the detection limit for arsenic to be as low

as 0.15 wt. % (Table 2), and the 20 nA beam current at 15 kV for the sulfides allowed an

arsenic detection limit down to 0.04 wt. % (Table 3). Detection limits were calculated

using a standard procedure for calculating detection limits from electron microprobe data

(Scott, 1995; Reed, 2005). Quantified mineral compositions were collected by comparing

the compositions to well-characterized reference materials (Table 4). Standards used for

the elements analyzed in oxides are shown in Table 4 for: Al, As, Ca, Co, Fe, K, Mn, Na,

Ni, O, Pb, S, Sb, Si, and Ti; Standards used for the elements analyzed in sulfides are

shown in Table 4 for: As, Fe, Co, Cu, Ni, S, Si, Sb, and Zn. Data were stored in Excel

spreadsheets. Programs such as OriginLab Corporation’s OriginLab 8.5.1 (Northampton,

Massachusetts) and Systat Software, Inc.’s SigmaPlot 11.0 (Chicago, Illinois) were used

to analyze the data statistically and to make plots. Backscatter Electron (BSE) images

were collected using the electron microprobe to characterize the textures present in the

mineral grains explored. BSE images are greyscale, and the higher the mean atomic

number of the minerals being explored, the brighter that mineral appears in the image.

This allowed for textures such as zoning within grains (e.g. pyrite) to be seen.

16

Table 2

Element Detection Limits: Oxides (Wt. %)

Table 2 Calculated oxide detection limits for electron microprobe. Detection limits were

calculated using the standard procedure for calculating detection limits (Scott, 1995;

Reed, 2005). Counts that were below the detection limit based on 6σ were eliminated.

The oxide mineral detection limit for arsenic found in samples from EMSHP was

calculated as 0.15 wt. %. All Sb and Ti points analyzed were below their calculated

detection limit of 0.02 wt. %. AD – All analyses were above detection limit.

17

Table 3

Element Detection Limits: Sulfides (Wt. %)

Table 3 Calculated sulfide detection limits for electron microprobe. Detection limits were

calculated using the standard procedure for calculating detection limits (Scott, 1995;

Reed, 2005). Counts that were below the detection limit based on 6σ were eliminated.

The sulfide mineral detection limit for arsenic found in samples from EMSHP was

calculated as 0.04 wt. %. Silica was analyzed for quality assurance that silicates were not

involved in the analyses. AD – All analyses were above detection limit and are therefore

detection limit not reported.

18

Table 4

Electron Microprobe Standards

Table 4 Electron microprobe standards used for calibration of elements in oxides and

sulfides. The mineral name and respective formula for each standard is listed. x –

Element was not analyzed.

19

Criteria for refining sulfide data were based on existing research on similar

methods used by Paktunc et al. (2004). Sulfide analyses with totals less than 98 wt. % or

greater than 102 wt. % were not included in the final results (S. Roeske, written

communication, 2012). Data are reported for Si in sulfides to demonstrate minimal

interference from adjacent silicate grains. Criteria for refining oxide data were based on

expected totals for the HFO minerals ferrihydrite and goethite of approximately 81% and

90%, respectively; oxide analyses with totals less than 75 wt. % were excluded. Analyses

with silica content that fell between 0-15 mole % (equivalent to 4.2 wt. % as Si) were

accepted based on the observed limit of adsorbed silica onto natural HFO found in

Finland (Carlson et al., 1981). Weight percent components that had a total As2O5+Fe2O3

greater than 90 wt. % were taken out to allow for the presence of water in hydrous

oxides, and the lower bound for wt. % components was set at 48 wt. % to keep As-rich

jarosite within the analyses (Paktunc et al., 2004). The boundary between HFA and HFO

was determined by calculating the Fe:As molar ratio from the electron microprobe

analyses. Material with a Fe:As molar ratio less than 3 was named hydrous ferric arsenate

(HFA) and material with a ratio greater than 3 was considered as HFO (Walker et al.,

2009). This break between HFO and HFA represents about 18 wt. % arsenic. The HFO is

considered to consist of the minerals ferrihydrite and goethite whereas the HFA is

considered to represent a nano-scale mixture of arsenical ferrihydrite and poorly

crystalline ferric arsenate with composition similar to that of scorodite (Paktunc et al.,

2008).

20

METHODS SUMMARY

Synchrotron-based spectroscopy, QEMSCAN, and electron microprobe were

employed during the mapping and quantification of the mine waste pile rock samples

from Empire Mine State Historic Park. Data from the Synchrotron and QEMSCAN were

used to create element and mineral maps. The Synchrotron data were used to generate

element vs. element plots using X-ray point counts to show trends between elements.

Although not directly quantitative, spatial relationships between arsenic and iron were

derived using the Synchrotron and QEMSCAN methods. The electron microprobe was

used to determine the composition of primary sulfides (i.e. arsenopyrite, low-arsenic

pyrite, arsenian pyrite, and cobaltite) and secondary oxide minerals (hydrous ferric

oxides, HFO, consisting of goethite and ferrihydrite; hydrous ferric arsenate, HFA; and

scorodite); the electron microprobe data represent quantitative weight percent

composition for several elements for individual grains. The combination of spatial and

quantified data across the methods has been used to characterize high-arsenic primary

minerals and their respective weathering products at several mine sites within EMSHP.

21

Chapter 3

RESULTS

SULFIDE COMPOSITION FROM ELECTRON MICROPROBE ANALYSIS

Primary arsenic-bearing sulfides at EMSHP included: pyrite, arsenian pyrite,

arsenopyrite, and cobaltite (Table 1). Data for arsenic concentration in primary sulfide

minerals from electron microprobe analysis are shown in Figure 3. Detectable arsenic

values in pyrite ranged from 0.2 to 5.1 wt. %, in arsenopyrite ranged from 40.1 to 44.2

wt. %, and in cobaltite ranged from 44.0 to 44.8 wt. % (Table 5). A plot of the cumulative

distribution of arsenic concentration in pyrite across all sites (Figure 4) shows two breaks

in slope, at approximately 0.15 and 1.0 wt. %, indicating a tri-modal distribution.

Therefore, for the purpose of discussion, pyrite has been broken down into three

categories of arsenic concentration: low-arsenic (less than 0.15 wt. %), medium-arsenic

(0.15 to 1 wt. %), and high-arsenic (greater than 1 wt. %) pyrite (Figure 4, Figure 5). The

relative proportions of low-, medium-, and high-arsenic pyrite are fairly equal (30 to 35

% of each type) when considering all sites (Figure 6), however some spatial variations

are evident when broken down by site (Figure 7). One notable spatial trend is the greater

abundance of low-arsenic pyrite at the Power Line East, Woodbury South, and Woodbury

North sites (Figure 7), which are located in the southern portion of the EMSHP (Figure

8).

22

Figure 3 Box plot for the arsenic concentrations in primary and secondary minerals at

EMSHP analyzed by electron microprobe. Boxes represent the statistical percentile

distribution of data for each respective mineral. Maximum arsenic content of HFO (17.9

wt. %) in some analyses exceeds that of arsenian pyrite (5.1 wt. %). The detection limit

for arsenic in sulfides is 0.04 wt. % and in oxides is 0.15 wt. %, calculated using the

standard procedure outlined by Scott (1995) and Reed (2005). All points below their

respective detection limit for sulfides or oxides were plotted at half the detection limit.

HFO – hydrous ferric oxide, HFA – hydrous ferric arsenate.

23

Table 5

Summary of Sulfide Composition Data for All Sites

Table 5 Summary table for sulfide electron microprobe data (in wt. %) highlighting the

minimum, maximum, average, total analyzed points (n(total)), and number of values

below detection (n(non-detects)) for each mineral. Data were screened to exclude

unreliable totals below 98 wt. % and above 102 wt. %. Si is not in solid solution with

sulfides, but is reported to demonstrate minimal interference from adjacent silicate grains.

Values are reported to the hundredths place to avoid rounding errors although in some

cases the tenths place represents the most appropriate number of significant figures.

*Average includes data points above detection only.

24

Figure 4 Cumulative distribution of arsenic concentrations of arsenian pyrite grains

across all sites sampled. Two breaks in slope around 0.15 wt. % and 1 wt. % indicate a

tri-modal distribution, allowing for the segregation of arsenian pyrite into three

categories: low arsenic (less than 0.15 wt. %), medium arsenic (0.15 to 1 wt. %), and high

arsenic (greater than 1 wt. %). Calculated detection limit for arsenic in sulfides is 0.04 wt.

%, and all points below detection were plotted at half the detection limit.

25

Figure 5 Box plot for the arsenic concentrations in primary and secondary minerals at

EMSHP analyzed by electron microprobe. Low arsenic (less than 0.15 wt. %), medium

arsenic (0.15 to 1 wt. %), and high arsenic (greater than 1 wt. %) pyrite are distinguished.

The detection limit for sulfides is 0.04 wt. % and for oxides is 0.15 wt. %, calculated

using the standard procedure outlined by Scott (1995) and Reed (2005). All points below

their respective detection limit for sulfides or oxides were plotted at half the detection

limit. HFO – hydrous ferric oxide, HFA – hydrous ferric arsenate.

26

Figure 6 Low- (<0.15 wt. %), medium- (0.15 – 1 wt. %), and high- (>1 wt. %) arsenic

pyrite and hydrous ferric oxide (HFO) across all sites. Low-, medium-, and high-arsenic

pyrite appear with similar frequency, whereas HFO shows a more frequent occurrence of

high arsenic HFO (>1 wt. %) than lower concentrations. Numbers printed above each

column represent number of data points, ‘n’.

27

Figure 7 Low- (<0.15 wt. %), medium- (0.15 – 1 wt. %), and high- (>1 wt. %) arsenic

pyrite and HFO plotted by site. Only sites with both arsenian pyrite and HFO data are

displayed. Six out of seven sites show a more frequent occurrence of high arsenic HFO,

the exception being Woodbury North which shows the opposite trend. Numbers printed

above each column represent number of data points, ‘n’.

28

Figure 8 Distribution of low, medium, and high arsenic pyrite and HFO across all sites.

Shades of orange indicate arsenic in pyrite, and shades of blue indicate HFO with arsenic

increasing to the right for both data sets (as in Figure 7). Northern and central sites have a

higher occurrence of higher arsenic pyrite and HFO, while the southern sites have a

higher occurrence of low arsenic minerals. One site, Woodbury North, shows a complete

opposite trend of more frequent low arsenic pyrite and HFO.

29

OXIDE COMPOSITION FROM ELECTRON MICROPROBE ANALYSIS

Secondary oxide minerals found at EMSHP include several minerals with more

than 20 wt. % arsenic such as poorly crystalline or amorphous hydrous ferric arsenate

(HFA); the Fe-arsenate mineral scorodite; and unidentified Ca-Fe-arsenates (Table 6). In

addition, several secondary minerals with less than 20 wt. % arsenic were observed,

including the hydrous ferric oxide (HFO) minerals ferrihydrite and goethite, and jarosite,

a K-bearing ferric-sulfate-hydroxide mineral (Table 1). HFO contained silica (Si) from

0.0 wt. % up to 4.2 wt. %. The distribution of arsenic concentration in HFO and HFA at

all sites analyzed can be seen in Figures 3 and 5. Elemental arsenic concentration in HFA

(including scorodite) ranged from: 16 wt. % to 48.1 wt. %, and arsenic concentration in

HFO ranged from 0.2 to 17.9 wt. % (Table 7).

The cumulative distribution of arsenic concentration in HFO is plotted alongside

that of pyrite (Figure 9). For the sake of comparison with pyrite (Figure 6), HFO was

divided into low-arsenic HFO (less than 0.15 wt. %), medium-arsenic (0.15 to1 wt. %),

and high-arsenic HFO (greater than 1 wt. %) using the same categories as pyrite. Figure 6

shows the distribution of arsenic in HFO at all sites, with high-arsenic HFO appearing

significantly more frequently than low-arsenic and medium-arsenic. Six of seven sites

show high-arsenic HFO as the most abundant type of arsenic-bearing HFO; the exception

is Woodbury North (Figure 7), located in the southern end of the sampled sites (Figure

8). The higher abundance of high-arsenic HFO compared with low- and medium-arsenic

HFO at most of the sample sites (Figure 7 and Figure 8) is reflected in plots showing data

from all sites (Figure 6 and Figure 10).

30

Table 6

Unknown Ca-Fe Arsenates

Table 6 Apparent composition of unknown Ca-Fe arsenate minerals from Power Line

Central (P2) and Power Line East (G1). The electron microprobe analysis points for

Power Line East (G1) were clustered and of similar composition, so the 13 points were

averaged together. Estimated water of hydration calculated by difference based on

electron microprobe totals as oxides.

31

Table 7

Summary of Oxide Composition Data for All Sites

Table 7 Summary table for oxide electron microprobe data (in wt. %) highlighting the

minimum, maximum, average, total analyzed points (n(total)), and number of values

below detection (n(non-detects)) for each mineral. Data were screened to exclude

unreliable points with silica >4.2 wt. % (Carlson et al., 1981), and totals below 75 wt. %

as a conservative estimate based on the model for ferrihydrite for which an 80 wt. % total

is expected. Values were rounded to the hundredths place to avoid rounding errors,

although the tenths place may be a more appropriate number of significant figures.

Analyzed Mn, Sb, and Ti points were all non-detects and were removed from the list due

to detection limits of 1.58 wt. %, 0.02 wt. %, and 0.02 wt. %, respectively. *Average

includes data points above detection only.

32

Figure 9 Cumulative distribution of arsenic concentration in HFO and pyrite. The HFO

trend is higher than the pyrite trend, indicating that HFO contains more weight percent

arsenic than pyrite. Material with a molar Fe:As ratio less than 3:1 was considered HFA

and therefore is not shown. See figure 4 for description of pyrite trend.

33

Paktunc et al. (2004) created a plot with electron microprobe data for arsenicbearing oxides from the Ketza River mine tailings, Yukon, Canada, based on the weight

percent As2O5 versus Fe2O3 with diagonal lines representing values of constant molar

ratio between As2O5 to Fe2O3 for model compounds ranging from HFO to HFA. Data

from this study are compared to those from Paktunc et al. (2004)’s As2O5 versus Fe2O3

plot in Figure 11. Potential Ca-Fe-arsenates were also plotted in a diagram similar to

Paktunc et al. (2004)’s CaO versus As2O5 plot (Figure 12), with a diagonal line

representing the constant molar ratio (0.67) between CaO and As2O5 for arseniosiderite.

Comparison of the Paktunc et al. (2004) diagram for As2O5 versus Fe2O3 (Figure 11) and

for CaO versus As2O5 (Figure 12), and examination of electron microprobe analyses has

confirmed the presence of scorodite, jarosite, ferrihydrite, and goethite, and unknown CaFe arsenates in the EMSHP samples. Ternary diagrams with electron microprobe data

and model compounds (Figures 13.A to 13.D) show some analyzed points that align with

model compounds or show apparent mixing lines between unknown end members

(Figure 14).

There are two linear trends that appear to have distinct end members in Figure 12,

including one trend that is > 25 wt. % As2O5 and > 3 wt. % CaO, in addition to a

grouping of points that all share a similar composition around 30-35 wt. % As2O5 and 4-6

wt. % CaO. There is a trend of analyzed points from Power Line Central samples, and a

grouping of analyzed points from Power Line East. The trend could represent mixing

lines between end members that are not currently plotted, or some combination mixing

line between jarosite, yukonite, and/or some other end member. The compositions of

34

these unknown minerals are plotted in Figure 14. On a molar basis, the linear trend of

unknown Ca-Fe arsenates from Power Line Central is relatively consistent in calcium

content but varies most widely in their iron content. A possible stoichiometry for the lowiron end of the Power Line Central trend is Ca3Fe7(AsO4)6(OH)9•7H2O (P2 in Figure 14

and Table 6). The compositions of the Power Line East cluster were averaged due to their

very similar stoichiometries and a possible chemical formula for this unknown Ca-Fe

arsenate is Ca3Fe24(AsO4)10(OH)48•9H2O (G1 on Figure 14 and Table 6).

COMPARISON OF SULFIDE AND OXIDE COMPOSITIONS

The concentration of arsenic in pyrite (0.2 wt. % to 5.1 wt. %) is lower than the

concentration of arsenic in HFO (0.2 wt. % to 17.9 wt. %) based on electron microprobe

analyses (Figures 3, 9 and 10). Arsenic in HFA (16 wt. % to 48.1 wt. %) overlaps the

range for arsenic in arsenopyrite (40.1 wt. % to 44.2 wt. %) however the maximum

arsenic in HFA exceeds that in arsenopyrite by approximately 5 wt. % (Tables 5 and 7).

Overall there is a higher distribution of arsenic in high-arsenic HFO compared with that

in high-arsenic arsenian pyrite from all sites combined (Figure 9). By site, there is a

greater occurrence of medium- and high-arsenic arsenian pyrite in four out of seven

samples sites at EMSHP, and a greater occurrence of medium- and high-arsenic HFO in

five out of the seven sampled sites.

Four grains of weathered pyrite with HFO and five grains of weathered

arsenopyrite with HFA were analyzed to determine the relationship of iron and arsenic

transport from the primary minerals to the secondary weathering products. Grains were

selected based on analyses available for both a sulfide and corresponding secondary

35

oxide, representing a direct relationship between the primary and secondary minerals

within a single original sulfide grain. A bidirectional plot of the As:Fe molar ratio (Figure

15) shows the average composition of the primary mineral and secondary minerals based

on electron microprobe data for each respective grain of pyrite/HFO and

arsenopyrite/HFA, and error bars show the standard deviations. Two types of weathering

are shown (Figures 15.A-I): a rimming weathering texture in the grain (represented by a

circle on the bidirectional plots) or core weathering of each grain (represented by a

triangle on the plots).

Pyrite, arsenopyrite, and their respective weathering products were plotted with a

linear regression (Figure 15). The 2:1, 1:1, and 0.5:1 lines represent the molar ratio

between the As:Fe in oxides and in sulfides. The regression line between the pyrite/HFO

and arsenopyrite/HFA in Figure 15 falls between the 0.5:1 and 1:1 line with a slope (b[1])

of 0.675. Most grains fall close to or within the 95% confidence interval with the

exception of two arsenopyrite grains. The regression slope for just the pyrite/HFO grains

(Figure 15) is 2.05. In addition to the four pyrite/HFO points shown in Figures 15 and 16,

which have medium- and high-arsenic pyrite and HFO, a fifth grain that was analyzed

(but not plotted or included in the linear regressions) had concentrations of arsenic below

detection in both pyrite (< 0.04 wt. %) and HFO (<0.15 wt. %). The distribution of the

five arsenopyrite grains in terms of weight percent in Figure 16 show a relatively constant

concentration of arsenic in sulfide, with variations in the arsenic content of HFA,

consistent with the trend shown in Figure 15.

36

One sample, a thin section containing pyrite, arsenopyrite, HFO, and HFA from a

rock collected in the Prescott Shaft Area site, was analyzed using all three microbeam

techniques (electron microprobe, XAS, and QEMSCAN). A QEMSCAN scan of the

Prescott Shaft thin section (Figure 17) shows weathering of pyrite to HFO and

arsenopyrite weathering to HFA. Linear trends in Figure 17, column 3 represent

uncalibrated point counts for the As90 versus Fe90 channels collected from Beamline 2-3

using X-ray absorption spectroscopy (XAS), and the slopes listed are for the upper and

lower bound of each encircled linear trend.

Each encircled trend on Figure 17 represents points that were ‘masked’ or

separated out from the rest to focus on whether that trend was associated with a primary

or secondary mineral. None of the slopes overlap, indicating that there are distinct phases

present, and the As:Fe ratio in column 2 shows that there is an increasing amount of

arsenic from arsenian pyrite+HFO up through HFA and arsenopyrite. Points for arsenian

pyrite and HFO were lumped together in Figure 17 because the two phases when

separated did not match up well with the QEMSCAN data for the pyrite and HFO in

Figure 17; and the combined the As:Fe ratio and slope of the mask is distinctly different

from HFA and arsenopyrite.

37

Figure 10 Box plot showing the arsenic concentrations in pyrite and HFO at EMSHP

analyzed by electron microprobe. Low-arsenic (less than 0.15 wt. %), medium-arsenic

(0.15 to 1 wt. %), and high-arsenic (greater than 1 wt. %) pyrite and HFO are

distinguished. The distribution for low-arsenic HFO includes 2 points above detection

limit and 51 points below detection limit, so only 90% and 75% percentile were plotted.

The detection limit for arsenic is 0.04 wt. % in sulfides and 0.15 wt. % in oxides,

calculated using the standard procedure outlined by Scott (1995) and Reed (2005). All

points below their respective detection limit for sulfides or oxides were plotted at half the

detection limit. HFO – hydrous ferric oxide.

38

Figure 11 Analyzed electron microprobe variation of As2O5 versus Fe2O3. HFO minerals

goethite and ferrihydrite contain approximately 10 wt. % and 20 wt. % H2O, respectively,

so As2O5+Fe2O3 totals >90 wt. % and <75 wt. % were excluded to allow for water

content. Negative oxide analyses were converted to zero. Diagonal lines are Fe/As molar

ratios with arrows pointing to theoretical mineral compositions. A larger number of

analyzed points fall within the ‘coprecipitate’ range at EMSHP (top) compared to the

39

Ketza River mine (bottom, figure from Paktunc et al. (2004)), and EMSHP has

compositions with >50 wt. % arsenic that do not match any of the theoretical compounds

plotted. Goethite at EMSHP does show up in electron microprobe analyses, but does not

plot at the goethite theoretical compound most likely due to the inclusion of arsenic.

40

Figure 12 Analyzed electron microprobe variation of CaO versus As2O5. Yukonite has

several formulas (Garavelli et al., 2009), and yukonite arrows point to two of those

compositions. Negative oxide analyses were converted to zero. The 0.67 diagonal line is

the Ca/As molar ratio for arseniosiderite. Clusters of data near arseniosiderite and jarosite

41

compositions were seen at the Ketza River mine (bottom, Paktunc et al., 2004) but not at

Empire Mine (top, this study). A trend of unknown mineral compositions is present at

EMSHP (top) that is not seen from Paktunc et al. (2004)’s Ketza River mine analyses

(bottom). Two possible stoichiometries were calculated for analyzed points in this

unknown trend and are P2 = Ca3Fe7(AsO4)6(OH)9•7H2O and G1 =

Ca3Fe24(AsO4)10(OH)48•9H2O as seen in Table 6.

42

Figure 13 Ternary diagrams showing electron microprobe components in weight percent.

Model compounds are labeled with stars and model compounds that are projected

(because they contain other components not plotted) are in parentheses. In 13.A (top), the

43

majority of points cluster on the CaO+Fe2O3 - As2O5 axis, and in 13.B (bottom) points

cluster on the Fe2O3 - As2O5 axis with the exception of the trend of grey and pink points

representing unknown Ca-Fe arsenates.

44

Figure 13 (Continued) Ternary diagrams showing electron microprobe components in

weight percent, continued. Model compounds are labeled with stars and model

compounds that are projected are in parentheses. In 13.C (top), the addition of water

evens out the distribution of analyses with the majority of points containing 10 wt. % to

45

20 wt. % H2O (calculated by difference from 100 wt. % oxides). Ternary 13.D (bottom)

confirms that potassium-bearing minerals such as pharmacosiderite and jarosite are not

abundant at EMSHP.

46

Figure 14 Unknown Ca-Fe arsenates from Power Line Central and Power Line East sites.

Data points are plotted in weight percent. P2 and G1 are the calculated formulas for the

unknown Ca-Fe arsenates. P2 = Ca3Fe7(AsO4)6(OH)9•7H2O, and G1 =

Ca3Fe24(AsO4)10(OH)48•9H2O. The Power Line Central data points have variable iron

content, with low and high iron phases whereas the points from Power Line East are

clustered. Power Line East points were averaged together due to similar compositions.

47

Figure 15 Molar bidirectional plots for pyrite/HFO and arsenopyrite/HFA with grain textures. Diagonal lines

indicate As:Fe molar ratios in oxides and sulfides. Triangles represent core weathering of grains and circles

47

represent rimming. Pyrite/HFO and arsenopyrite/HFA (top) have a slope of 0.675 but pyrite/HFO alone

48

(bottom) has a steeper slope of 2.05. Brighter areas in BSE images represent higher mean atomic weight.

Pyrite/HFO grains: Sebastopol (A), Empire Mine Dump (B (soil), D), Prescott Shaft Area (C).

Arsenopyrite/HFA grains: Power Line East (E), Prescott Shaft Area (F, G), Betsy (H), Prescott Shaft Area (soil)

(I). All BSE images illustrate rim weathering textures, but images B and D also represent core weathering.

48

49

Figure 16 Weight percent bidirectional plots for pyrite/HFO and arsenopyrite/HFA with

grain textures. Triangles represent core weathering of grains and circles represent

rimming. Pyrite/HFO and arsenopyrite/HFA (top) have a slope of 0.576 whereas

pyrite/HFO alone (bottom) has a steeper slope of 2.05. Most grains of pyrite/HFO and

arsenopyrite/HFA (top) fall within the 95% confidence interval and most plot close to the

regression line.

50

Figure 17 QEMSCAN and XAS images from a Prescott Shaft thin section. The

QEMSCAN image (top) shows the spatial relationship between pyrite/HFO and

arsenopyrite/HFA with letters corresponding to the bottom image. Linear trends (bottom)

51

are non-quantitative point counts for As vs. Fe collected from Beamline 2-3. Slopes listed

are for the upper and lower bound of each encircled linear trend. The slopes for pyrite

and HFO could not be completely separated, so they are combined, but the top image

shows the break between pyrite and HFO (hydrous Fe oxides).

52

Chapter 4

DISCUSSION

SULFIDE MINERALS

Three primary arsenic-bearing sulfide minerals were identified from electron

microprobe analysis (Appendix B): arsenian pyrite (As up to 5.1 wt. %), arsenopyrite (As

up to 44.2 wt. %), and cobaltite (As up to 44.8 wt. %) (Table 5). Bulk analyses of

arsenian pyrite from the Clio Mine in Tuolumne County within the Mother Lode have

shown arsenic levels as high as 5 wt. % (Savage et al., 2000), and arsenic in auriferous

arsenian pyrite from an unknown locality has been recorded at 9.3 wt. % under formation

temperatures between 300°C and 500ºC, and pressures of 1.3-1.6 kilobars (Reich et al.,

2005). However, arsenian pyrite in a stable solid solution can host up to 6 wt. % arsenic,

with arsenic values >6 wt. % representing a metastable phase of arsenian pyrite prone to

un-mixing into a combination of FeS2+FeAsS (Reich et al., 2006). Based on the

maximum 5.1 wt. % arsenic in arsenian pyrite at EMSHP, the arsenian pyrite falls below

the maximum for a stable solid solution.

Heterogeneities observed in some pyrite grains at Empire Mine (Figure 18)

included compositional zoning (light and dark regions within a competent pyrite grain)

that may indicate generations of growth in the grains from interactions with ore-forming

fluids. Arsenian pyrite within the Clio Mine also displayed compositional zoning,

indicating that physical and chemical conditions during crystal growth were not uniform

(Savage et al., 2000).

53

Figure 18 Backscatter electron images of zoned arsenian pyrite from two EMSHP

localities. Light and dark regions within each euhedral to sub-euhedral arsenian pyrite

grain represent heterogeneities in the form of higher and lower arsenic content,

respectively. Relatively lighter regions within the grains contain more arsenic (higher

mean atomic number, z), and darker areas contain less arsenic (lower z). These

heterogeneities may be responsible for core weathering textures observed in other

samples, as arsenic-rich areas may preferentially weather faster than lower-arsenic areas

due to increased electric and ionic conductivity when arsenic substitutes for sulfur in

pyrite (Savage et al., 2000).

54

Arsenic-rich regions in zoned pyrite preferentially undergo dissolution compared

to the low-arsenic zones because of the increase in electrical and ionic conductivity that

occurs when arsenic substitutes for sulfur in pyrite (FeS2 to Fe(S,As)2) as a solid solution

(Savage et al., 2000). So compared to arsenic-free pyrite, arsenian pyrite has the potential

to weather faster and release arsenic. A linear regression slope that lies below the 1:1

As:Fe molar ratio line for pyrite and arsenopyrite grains confirms that arsenic is being

released during weathering in the EMSHP samples (Figure 15).

Arsenopyrite can have variable arsenic content from about 41.6 wt. % to 50 wt.

%, depending on the pressure and temperature conditions under which the mineral forms

(Sharp et al., 1985). The arsenopyrite in samples from EMSHP has arsenic ranging from

40.1 wt. % to 44.2 wt. % (Table 5) and included grains with textures ranging from

euhedral and un-weathered to partially weathered with rims (Figure 15E - I). During

subaerial weathering of arsenopyrite, the oxidation of arsenic in the primary mineral

produces an acidic environment, forming As(V) and Fe(III) that can sorb onto ferric

hydroxide surfaces and allow for the formation of reaction rims on arsenopyrite

(Kocourková et al., 2011). Reaction rims can be comprised of scorodite on arsenopyrite,

and may reduce atmospheric exposure and thus oxidation of the primary grain

(Kocourková et al., 2011).

Cobaltite analyzed in the EMSHP samples has a similar range of arsenic as in

arsenopyrite, falling between 44.0 wt. % and 44.8 wt. % (Table 5). This arsenic

concentration agrees with that found in two cobaltite samples in the literature, one from

an unknown locality and another from the Frood Mine in Sudbury, Ontario that

55

respectively contain 44.8 wt. % and 45.2 wt. % arsenic (Fleet et al., 1990). Cobaltite with

its pyrite-type crystal structure (Bayliss et al., 1982) may contribute arsenic to secondary

minerals during weathering, but no evidence of cobaltite weathering was located during

analysis of the EMSHP samples. However, arsenic is known to bond with metals such as

cobalt, nickel, and iron in primary minerals, and arsenate bonds with iron, nickel,

manganese, lead, and calcium in secondary minerals (Drahota and Filippi, 2009), so there

is a known association of arsenic in primary minerals such as arsenian pyrite,

arsenopyrite, cobaltite, and secondary arsenate minerals.

HYDROUS FERRIC OXIDE (HFO)

Secondary HFO minerals included goethite, ferrihydrite, and jarosite and

contained elemental arsenic in the range from 0.2 wt. % (detection limit for oxides) to

17.9 wt. % (Table 6). Arsenic-bearing HFO such as Fe-arsenate phases have intermediate

arsenic bioaccessibility compared to the high arsenic bioaccessibility of Ca-Fe arsenates

(Meunier et al., 2010). Fe-oxides can contain arsenic concentrations from trace amounts

up to about 22 wt. %, with goethite confirmed to have up to 33.6 wt. % As2O5 (Paktunc et

al., 2004). For this project, the presence of HFO was confirmed using scans of the thin

sections from QEMSCAN analyses (Figure 19) and quantitatively from electron

microprobe data (Appendix C). Goethite and ferrihydrite were also confirmed in samples

taken from the same locations using bulk powder XRD (A. Blum, written

communication, 2011) and by Fe-EXAFS (A. Foster, written communication, 2011). The

cutoff point for maximum arsenic in HFO was determined by calculating the molar Fe:As

ratio from the electron microprobe analyses. For this project, any molar Fe:As ratio less

56

than or equal to 3 was named HFA and any ratio greater than 3 was considered as HFO

based on the criteria of Walker et al. (2009). On the basis of this ratio, the maximum

arsenic in HFO for this study was defined as <18 wt. % (Table 6).

The mean concentration of arsenic in HFO exceeds that of arsenic in arsenian

pyrite at six of the seven mine waste sites in EMSHP. Higher concentrations of arsenic in

secondary HFO than in the primary sulfide mineral, pyrite, is a repeating trend that is

seen in the box plots and in most of the histograms created for arsenic in pyrite and HFO

across all sites and within individual sites (Figure 6, 7, 10). This trend of higher arsenic

levels in HFO weathering products than in pyrite was also observed at the Clio Mine,

which is also within the Mother Lode belt (Savage et al., 2000).

In the samples analyzed as part of this study, the arsenic content in HFO fell

within the range of arsenic for pyrite or higher (Figure 3). The most likely explanation for

this is the addition of As to HFO after the weathering of pyrite. The excess of arsenic

sorbing onto the HFO most likely comes from the release of arsenic from the weathering

of arsenopyrite to HFA in nearby grains. The relationship between the arsenic in the

weathering of pyrite and arsenopyrite (Figure 15) is compared to the 2:1, 1:1, and 0.5:1

lines representing the molar ratio between As:Fe in oxides and sulfides. The regression

line between arsenic in the weathering of pyrite and arsenopyrite has an r2 value of 0.852,

representing a good fit between the pyrite/HFO data and the arsenopyrite/HFA data and

supporting a relationship between the two data sets. Taken alone, the r2 value for As:Fe in

sulfide vs. oxide for just the four grains of pyrite/HFO is 0.782 (Figure 15.B).

57

Figure 19 QEMSCAN image illustrating the presence of pyrite/HFO and

arsenopyrite/HFA at EMSHP. In the color key, “Fe Oxides” represent HFO minerals (e.g.

ferrihydrite and goethite), and “Fe-Oxide-As” represents high arsenic oxides, or HFA.

Rimmed pyrite and arsenopyrite grains are surrounded by a quartz and feldspar rich

matrix, consistent with the geologic setting of mineralized quartz-rich veins at EMHSP.

58

HFA may contain Ca-Fe arsenates that readily release As(V), which in turn readily sorbs

onto HFO surfaces (Meunier et al., 2010) and in greater quantities than arsenate would

bond to such minerals as goethite (Welch et al., 1998).

Fe(III) oxyhydroxide dissolution occurs at < 3.5 pH (Gunsinger et al., 2006),

therefore Fe(III) is highly insoluble at near-neutral pH, and it is reasonable to assume that

iron is immobile during weathering of Fe(III) arsenates in these conditions. If Fe(III) is

conservative in the solid phase, the 2:1 line indicates a doubling of arsenic because it is

sorbed from solution during weathering of pyrite to HFO, a 1:1 line represents

replacement (conservative behavior of both Fe and As), and 0.5:1 represents arsenic

liberation from the primary mineral. The regression line between the pyrite/HFO and

arsenopyrite/HFA (Figure 15) falls between the 0.5:1 and 1:1 line with a slope of 0.675,

supporting that arsenic is being released from arsenopyrite during weathering. The

relationship just within the arsenian pyrite and HFO grains (Figure 15) has a slope of

2.05, which can be interpreted as indicating that arsenic has doubled and was sorbed onto

HFO during the weathering of arsenian pyrite. So it appears that the excess of arsenic is

most likely sourced from the weathering of arsenopyrite to HFA, and sorbed onto the

HFO sites during the weathering of arsenian pyrite to HFO. HFO contain Si between 0.0

wt. % and 4.2 wt. % , but the high end may represent interference of adjacent silicate

grains during electron microprobe analyses. Silica on HFO from a deposit in Finland was

as high as 4.2 wt. % (calculated as Si) (Carlson et al., 1981), so may represent a more

reasonable estimate for the amount of silica that can naturally occur on HFO. Sorbed

silica can reduce the dissolution rate of goethite (an HFO mineral) (Eick et al., 2009), and

59

may be important for understanding the behavior for the dissolution of HFO in the human

gut and thus the interpretation of gastric leach (in vitro) bioaccessibility data (Alpers et

al., 2012).

HYDROUS FERRIC ARSENATE (HFA)

Secondary HFA minerals included scorodite and various Ca-Fe arsenates that

range in elemental arsenic concentration from 16 wt. % to 49.6 wt. % based on electron

microprobe analyses (Table 7). Ca-Fe arsenates are known to have relatively high arsenic

bioaccessibility (Meunier et al., 2010). The relatively high bioaccessibility is due to

longer atomic distances between the As-Ca bond (3.3Å) than the As-Fe bond (2.7Å) in

arsenates, making Ca-Fe arsenates relatively highly soluble and more likely to release

arsenic than other HFA minerals such as scorodite (Paktunc et al., 2004). Scorodite is not

considered a Ca-Fe arsenate phase, but can contain up to 2 wt. % CaO (Paktunc et al.,

2004). Because 13% of the HFA electron microprobe analyses in this study showed a

concentration of Ca above 2 wt. %, those HFA phases are considered as Ca-Fe arsenate.

The data points on the pink and grey trends of unknown CaO bearing Fe-arsenate

minerals (Figure 14) fall within the Ca-Fe arsenate category based on the distinction

made separating Ca in HFA minerals such as scorodite versus Ca in Ca-Fe arsenates. The

pink data points appear to be trending toward yukonite, which perhaps represents a

mixing line. However it is not clear what the cluster of grey data points represents, with

regard to known end member minerals or model compounds (Figure 12, 14). The average

formula for the clustered grey points (Ca3Fe24(AsO4)10(OH)48•9H2O) has a Ca:Fe:As ratio

of 1:8:3.33, and does not match the Ca:Fe:As ratio for the known Ca-Fe arsenate minerals

60

yukonite and arseniosiderite that are 3:1:2 and 2:3:3, respectively, and does not match

any stoichiometries found in the literature. Further work is needed on this sample to

determine if these analyses represent a single phase, perhaps of a composition not

previously recognized, or a mixture of known minerals.

61

Chapter 5

CONCLUSIONS

Arsenic in mine waste at EMSHP resides in the primary minerals arsenian pyrite,

arsenopyrite, and cobaltite and in secondary Fe(III)-oxide minerals ferrihydrite and

goethite (considered together as hydrous ferric oxides, HFO), scorodite, hydrous ferric

arsenate (HFA), and Ca-Fe arsenates. The concentration of arsenic in primary sulfide

minerals is as high as 44.8 wt. %, whereas the maximum arsenic concentration in

secondary minerals is 48.1 wt. %. The arsenic found in these secondary arsenate phases

originated in the arsenic-rich sulfides present in the waste rock. Analysis by electron

microprobe of HFO rimming and replacing arsenian pyrite revealed that the molar ratio

of As:Fe in HFO is about twice as high as the same ratio in associated arsenian pyrite.

The most likely explanation of this relationship is that arsenate was present in solution

during formation of the Fe oxides, and that some of this arsenate sorbed onto or

coprecipitated with HFO.