DOC 11MB - Australian Renewable Energy Agency

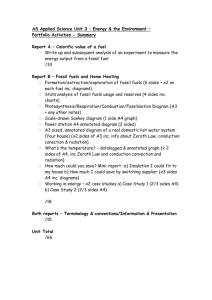

advertisement