Jeremy Jakubowski (Arizona State University)

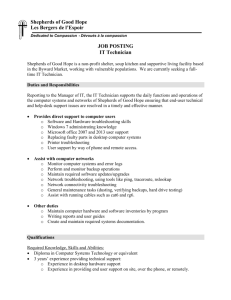

advertisement

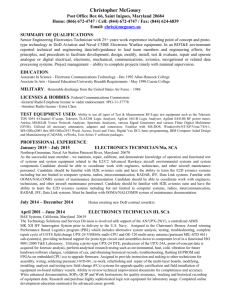

Jeremy Jakubowski 1556 W. 4 th Place, Mesa, AZ (602) 476-4631 JeremyJakubowski@hotmail.com Electronics Test Engineer and Software Developer Over 15 years’ experience working with electronic systems. Awarded multiple time for technical achievements and accomplishments. Experience working with engineering development teams. Specific experience with JTAG boundary scan and programming, RF circuits, networking, circuit board design, test equipment, test development, troubleshooting, and design verification. Quick learner and an electronics enthusiast. Extracurricular computer programming, computer networking, and computer repair training experience. Great focus on automation and test development. Maintained an active U.S. DOD secret security clearance for 8 years. Currently enrolled in ASUs Bachelor of Science degree in Computer Science at CIDSE. Extremely motivated to work professionally in the space exploration community Work Experience ASU SESE (School of Earth and Space Exploration) 11/2014 – present Title: Student Researcher Project lead for ASU’s ground station effort. Developed a complex excel document for all the preliminary calculations involved in both satellite and ground station communication systems. Developed orbital simulations and RF link modeling using AGI’s STK software utility. Produced preliminary designs and diagrams for the ground station system. Communications specialist for AOSAT satellite. Sand 9 12/2012 – 05/2013 Title: Electronics Validation Engineer Developed tests for validating MEMs resonators primarily using Python, Labview and Test-Stand languages. Worked closely with design engineering to validate new designs. Documented test results and presented reports both orally and written. General Dynamics 06/2007 – 12/2012 Title: Electronics Test Engineer/ Technician Performed complex system level and board level troubleshooting for developing products. Operated and programmed equipment such as In Circuit Test (ICT), Flying Head Verification (FHV), Automated Optical Inspection (AOI) and the CRX2000 Real-time X-ray machine. Experience troubleshooting and designing RF circuits for successful programs such as CM300 and JTRS-HMS. Designed Test Fixture assemblies and circuit boards for manufacturing test. Trained technicians on troubleshooting techniques and manufacturing process knowledge using detailed flow charts, procedures and group training sessions. Directed associates with performing rework processes to non-conforming products and test fixtures. Presented 5 high level awards for my direct development efforts for the JTRS-HMS program. Tasked with the lead role in developing automated test programs. The programs developed were for the initial manufacturing test and final software load configuration for the PRC-154 software defined radio. o Professionally documented, version controlled and distributed to partner companies. o Designed to help streamline engineering implementations to production units and for development/ demonstration efforts for the customer. o Captured test reports and performed test data analysis to achieve a 96% test yield o Developed test programs and scripts in languages such as python, batch, C++, visual basic, AutoIT, Labview and Test-stand. Work Experience Continued United States Navy 01/2002 – 01/2007 Title: Avionics Technician Honorable Discharge Job Duties: Troubleshot, replaced, and adjusted various electrical parts on the E6-B Mercury, CH-53E Helicopter, and Q14a underwater sonar unit. Some of these systems included pitot and static systems, AOA systems, intercom, amplifier and digital circuit boards, RF systems, wires and switches. Setup and operated ground support and test equipment, such as test carts, panels, and ground power units to perform functional and continuity test of the electrical and electronic systems. Volunteer work/ awards: Cracker Jacks Marching unit, Navy Battle E, Junior Sailor of the quarter and more. Education Arizona State University Mesa Community College Devry University 08/2014 – Present 01/2012 – 05/2014 03/2009 – 09/2009 United States Navy Avionics Technician Training Advanced electronics training core (16 weeks) AE/ A1 Common Core (8 Weeks) AE/ A1 Strand (15 weeks) 01/2002 – 01/2007 Technical training received: - Aircraft Electrical Systems - Electrical Troubleshooting - Electrical Test Systems - AC/ DC Theory - Training with Radio Frequency - Solder Certification - Q-14a Underwater Sonar Unit OJT - Solid State Circuit Electronics - Electrical Troubleshooting - Aircraft Instrument Systems Electrical Safety Fundamentals Electronics Laboratory Digital logic Circuits CH-53E Helicopter OJT (Avionics) E6-B Mercury OJT (Avionics, Plane Captain) Communication Receivers Electrical Test Instruments - Personal Fitness/ Conditioning Personal Finance Management Weapon Safety Additional training: - First Aid and Safety Pollution Control DOD Information Assurance Awareness Non-credited Training/ Accomplishments - - Plane Captain for E6b Mercury Hazmat safety coordinator Six-sigma training ASSET and XJTAG JTAG Boundary Scan Expirence with BF561 processor flash/ ram applications, Altera FPGAs, MSP430, Marvell flash/ Ram applications Clearcase database knowledge. - Corrosion Control Technician/ Instructor JTAG Programming and troubleshooting Solder Certified and ESD training Radiation safety certified/ X-ray operator SPI-By-Wire programming Computer repair (high school) Computer Networking (high school) Computer Programming (high school)