Lockout/Tag out

advertisement

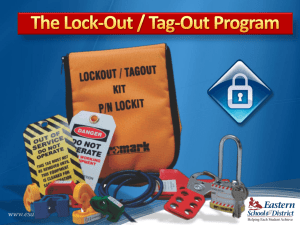

Policy and Procedure for Controlling Hazard Energy (Lockout/Tag out) OBJECTIVE: The control of unexpected start-up of machines and equipment, or the release of stored energy, in order to prevent workplace injuries or fatalities during service and/or maintenance operations. AUTHORITY: Vice President for Administration INTRODUCTION: Concordia University Chicago establishes this policy for the protection of employees who do service and/or maintenance of machines and equipment, and who could be exposed to injury or death by an unexpected energized, or start-up, or release of hazardous stored energy. Service or maintenance includes constructing, repairing, adjusting, inspecting, trouble-shooting, testing, cleaning, lubricating and dismantling of machinery or equipment. This policy applies to all university employees who may be exposed to hazardous energy during the course of performing service and/or maintenance work. The policy is not limited to electrical energy, but also includes chemical, thermal, pneumatic, hydraulic, and mechanical sources of potential/stored energy. EXPLINATION: Control of Hazardous Energy (29 CFR 1910.147) is a required OSHA standard for a Lockout/Tag out program. The standard requires employers to establish an energy control program that includes documented energy control procedures, an employee training program, and periodic inspection of the procedure. RESPONSIBILITIES: The following establishes specific responsibilities for the policy. 1. The Safety Officer is responsible for implementing and enforcing this policy. 2. All Authorized and affected employees must comply with this policy. 3. Supervisors must enforce the use of lockout/tag out devices when employees perform service and/or maintenance and may be exposed to hazardous energy. 1 4. Employees who perform service and/or maintenance work must follow the lockout/tag out procedures described in this policy. 5. Employees who work in areas where lockout/tag out procedures are used must understand the purpose of the procedures and are prohibited from attempting to restart machines and equipment that is locked or tagged out. 6. The Safety Officer will conduct a hazardous energy survey and magnitude of energy and necessary service and/or maintenance tasks. DEFINATIONS: Affected employee – A person who uses equipment that is being serviced under lockout or tag out procedures or who works in the area where equipment is being serviced. Authorized employee – A person who locks out or tags out equipment to perform service and/or maintenance work. Capable of being locked out – An energy isolating device that is designed with a hasp or other means of attachment to which, or through which a lock can be affixed, or if it has a locking mechanism built into it. Disconnect – A switch that disconnects an electrical circuit or load from the conductors that supply power to it. Under lockout procedure, the disconnect switch must be capable of being locked in the open position. Energized – Connected to an energy source or containing potential energy. Energy source – Any source of energy. Examples: electrical, mechanical, hydraulic, pneumatic, chemical and thermal. Energy-isolating device – A mechanical device that physically prevents transmission or release of energy. Hazardous energy – Any of the types of energy existing at a level or quantity that could be harmful to workers or cause injury or death through inadvertent release or start-up of equipment. Lockout device – A device that locks an energy-isolating device in the safe position. 2 Lockout – Placing a lockout device on an energy-isolating device, under an established procedure, to ensure the energy-isolating device and the equipment it controls can’t be operated until the lockout device is removed. Procedure – A series of steps taken to isolate energy and shut-down equipment. Qualified Person – A person who has been trained and is knowledgeable of the equipment and has been trained to recognize and avoid potential energy hazards that might be present. Servicing or maintenance – Workplace activities such as constructing, adjusting, inspecting, modifying and maintaining machines or equipment. Also includes lubricating, cleaning, and making adjustments if a worker may be exposed to the unexpected start-up of the equipment during such activities. Tag out device – A prominent warning sign, such as a tag, that can be securely fastened to an energy-isolating device to indicate that the energy-isolating device and the equipment it controls can’t be operated until the tag out device is removed. Tag out- Placing a tag out device on an energy-isolating device, under an established procedure, to indicate that the isolating device and the equipment it controls can’t be operated until the tag out device is removed. DEVICES: Lockout and tag out devices must meet the following criteria to ensure that they are effective and cannot be removed inadvertently: Lockout devices must work under environmental conditions in which they are used. Tag out device warnings must remain legible even when they are used in wet, damp, or corrosive conditions. Lockout and tag out devices must be designated by color, shape, or size. Tag out devices must have a standardized print and warning format. Lockout devices and tag out devices must be strong enough that they can’t be removed inadvertently. Tag out devices must be attached with a single-use, selflocking material such as a nylon cable tie. Any employee who sees a lockout or tag out device must be able to recognize who attached it and its purpose. Each lock must have a unique key. Energy-isolating devices are the primary means for protecting CUC employees who service equipment and must be designed to accept a lockout device. Energy-isolating devices must clearly identify function. 3 PROCEDURE: Controlling hazardous energy Authorized employees who lockout or tag out equipment or perform service and/or maintenance must follow specific written energy-control procedures. The procedures must include the following information: Intended use of the procedure Steps for shutting down, isolating, blocking and securing equipment Steps for placing, removing and transferring lockout devices Equipment-testing requirements to verify the effectiveness of the energy-control procedures Note: When re-energizing equipment is necessary and power is needed to test or position the equipment; temporary removal of the lockout or tag out devices is allowed. This applies only for the time required to perform the task and the procedure must be documented. Employees must do the following before they can begin service or maintenance work: 1. Inform all affected employees of the equipment shutdown. 2. Shut down the equipment that is to be worked on. 3. Isolate and/or block any hazardous energy. 4. Remove any potential (stored) energy. 5. Lockout or tag out all energy sources. 6. Verify that the equipment is isolated from any hazardous energy and is deenergized. Employees must do the following when they are removing lockout or tag out devices and reenergizing the equipment: 1. Make sure that all tools and material are removed and that all machine or equipment components and safety guards have been replace. 2. Inform co-workers about energy-isolating device removal. 3. Ensure that all workers are clear of the work area. 4 4. Verify that the machine or equipment power controls are in the off or in a neutral position. 5. Remove the lockout or tag out device. 6. Re-energize the equipment. Special lockout/tag out situations: 1. Energized testing – when an energy-isolating device is locked or tagged and it is necessary to test or position equipment. The following must be done: a. Obtain an energized electrical work permit from the Safety Officer. b. Remove unnecessary tools and materials from the equipment. c. Ensure that all other employees are away from the area. d. Remove locks or tags from energy-isolating devices. e. Proceed with the test or positioning. f. De-energize the equipment and replace the lockout or tag out energyisolating devices. g. Check to make sure that the equipment controls are de-energized. 2. Contract service or maintenance: CUC employees and outside contractors must be aware of their respective lockout/tag out procedures before the contractor does any onsite service or maintenance. CUC employees must understand and comply with the contractors energy-control procedures. 3. Group lockout: When authorized employees must service equipment that has several energy sources and several energy-isolating devices, the employees must follow a group lockout procedure. If there is more than one employee in the service team, all employees will have their lock on a multi-lock device with one employee being the lead. The lead employee will be the first to place their lock on and the last to remove their lock when everything has been verified to be ready to re-energize the equipment. 5 TRAINING: All employees who may be exposed to hazardous energy shall receive training to ensure that they understand CUC’s energy-control policy and use of energy controls. The training will meet the requirements of 29 CFR 1910.147 and the following: Authorized employees shall be trained to recognize applicable hazardous energy sources, the type and magnitude of the potential energy and the method necessary for energy isolation and control. Affected employees shall be trained in the purpose and use of energy control procedures. Other employees who work or may be in the area where lockout/tag out may occur shall be instructed about the procedure and the prohibition related to attempts to restart or re-energize machines and equipment that are locked out and/or tagged out of service. Employees shall be retrained whenever a change takes place in their job assignments, machines, equipment, or process, or when a change in the energy control procedure takes place. Retraining will also take place when an annual inspection reveals faults in the procedure. A record of all training for each authorized and affected employee shall be kept in their personal file in the H.R. office. PERIODIC INSPECTIONS: Periodic inspections will be performed and documented to ensure employee understanding and compliance of the energy control procedures. Documentation will include the following: The equipment on which the procedure was used. The date of the inspection. The employee(s) performing the procedure. If the procedure was performed correctly or not. Any follow-up training that was required as a result of the inspection. Name of the inspector. A lockout/tag out inspection must be performed at least annually. ADOPTED: May 25, 2011 Latest Review: November 5, 2014 6