Preparing Herbicide Solutions - Environmental Health and Safety at

advertisement

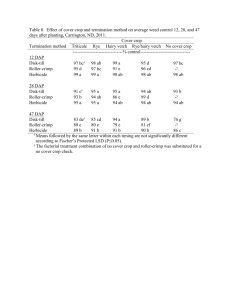

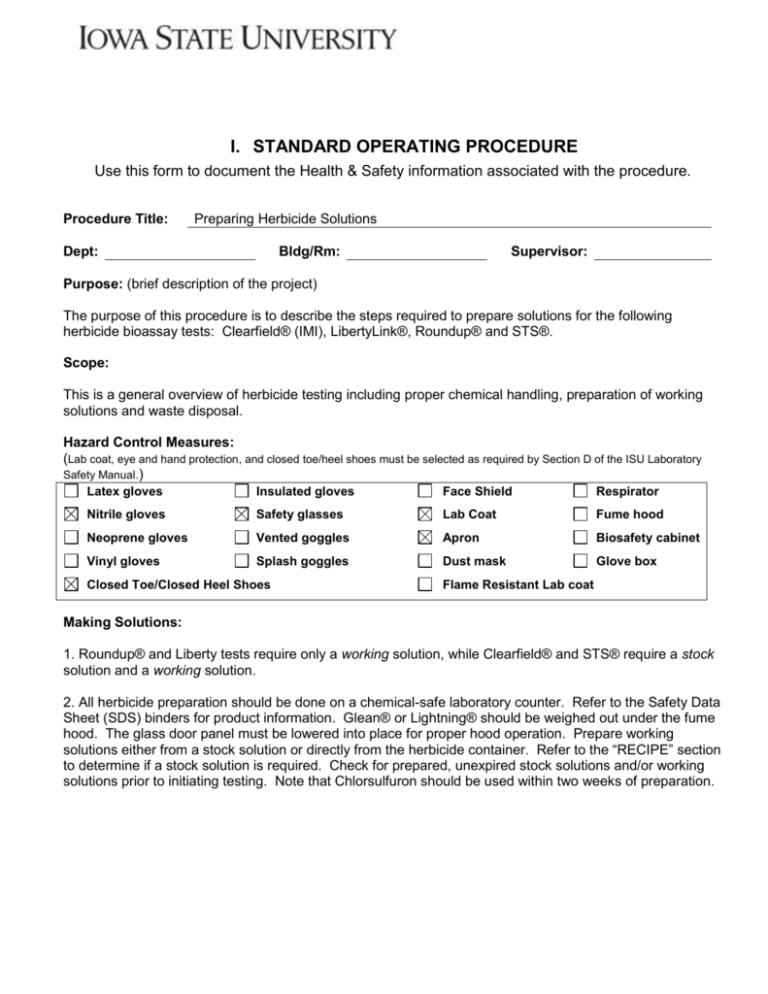

I. STANDARD OPERATING PROCEDURE Use this form to document the Health & Safety information associated with the procedure. Procedure Title: Preparing Herbicide Solutions Dept: Bldg/Rm: Supervisor: Purpose: (brief description of the project) The purpose of this procedure is to describe the steps required to prepare solutions for the following herbicide bioassay tests: Clearfield® (IMI), LibertyLink®, Roundup® and STS®. Scope: This is a general overview of herbicide testing including proper chemical handling, preparation of working solutions and waste disposal. Hazard Control Measures: (Lab coat, eye and hand protection, and closed toe/heel shoes must be selected as required by Section D of the ISU Laboratory Safety Manual.) Latex gloves Insulated gloves Face Shield Respirator Nitrile gloves Safety glasses Lab Coat Fume hood Neoprene gloves Vented goggles Apron Biosafety cabinet Vinyl gloves Splash goggles Dust mask Glove box Closed Toe/Closed Heel Shoes Flame Resistant Lab coat Making Solutions: 1. Roundup® and Liberty tests require only a working solution, while Clearfield® and STS® require a stock solution and a working solution. 2. All herbicide preparation should be done on a chemical-safe laboratory counter. Refer to the Safety Data Sheet (SDS) binders for product information. Glean® or Lightning® should be weighed out under the fume hood. The glass door panel must be lowered into place for proper hood operation. Prepare working solutions either from a stock solution or directly from the herbicide container. Refer to the “RECIPE” section to determine if a stock solution is required. Check for prepared, unexpired stock solutions and/or working solutions prior to initiating testing. Note that Chlorsulfuron should be used within two weeks of preparation. 3. If a pipette is used, be careful that herbicide is not drawn into the pipetting device. Pipettes should not be left in flasks as there is a danger of spillage. It is better to slide the pipette back into its wrapper. Used pipettes should be placed in a container designated for waste pick-up. Solutions should be thoroughly mixed by swirling or by using a magnetic stir bar and stir plate. 4. All waste herbicide-soaked towels or crepe cellulose paper are to be placed in garbage bags properly marked for that herbicide. These bags should be stored at 10o C to slow fungal growth. Herbicide Solution Recipes: • RR alfalfa substrate imbibition method (towels) Use Roundup® weatherMAX™ [48.8% (AI)] Glyphosate - Working solution (~700 ppm) - Add 5.74 mL weatherMAX™ to 4 L tap water • RR corn and RR soybeans substrate imbibition (crepe-cellulose paper) Use Roundup® weatherMAX™ [48.8% AI] Glyphosate - Working solution (~400 ppm) - Add 16.6 mL weatherMAX™ to 20 L tap water in designated carboy - Add ~ 1 mL red seed treatment color coating until solution has red tint • Clearfield® (IMI) corn Use Lightning™ [17.5/52.5% AI] - Stock solution (~3,000 ppm): Add 4.4 g Lightning™ to 1,000 mL tap water - Working solution (~9 ppm): Add 3.0 mL stock solution to 1,000 mL tap water • LibertyLink® corn Use Ignite 280® [24.5% AI] Glufosinate-ammonium - Working solution (~500 ppm) - Add 60 mL Ignite 280® to 20 L tap water in designated carboy - Add ~ 1 mL green seed treatment color coating until solution has green tint • LibertyLink® soybeans Use Liberty 200® [18.2% AI] Glufosinate-ammonium - Working solution (~20 ppm) - Add 2.4 mL Liberty 200® to 20 L tap water in designated carboy - Add ~ 1 mL yellow seed treatment color coating until solution has yellow tint • STS® soybeans Use Glean® [75% AI] Chlorsulfuron - Stock solution (~94 ppm): Add 62.5 mg (0.063g) Glean® to 500 mL tap water - Working solution (~9 ppm): Add 1.0 mL stock solution to 100 mL tap water - Storage for more than one week: Buffer solution to pH 7.5 with 1mm phosphate buffer and refrigerate. NOTE: ADJUST AMOUNT OF HERBICIDE ADDED TO STOCK/WORKING SOLUTIONS TO AID IN EVALUATIONS AND TO COMPENSATE FOR DIFFERENCES IN HERBICIDE FORMULATION. Waste Disposal Procedures: Handle and store herbicide waste following the guidelines above while accumulating wastes and awaiting chemical waste pickup. Waste must be disposed of following the Waste and Recycling Guidelines. http://www.ehs.iastate.edu/sites/default/files/uploads/publications/manuals/warg.pdf Contact EH&S Environmental Programs at 4-5359 for further assistance. First Aid Procedures: General advice Consult a physician. Show the SDS to the attending physician. In case of skin contact Immediately wash with soap and water and remove contaminated clothing. In case of eye contact Immediately rinse eyes with copious amounts of water for 15 minutes while occasionally lifting upper and lower eyelids. Seek medical attention. If inhaled Move the person to fresh air immediately and seek medical attention if large amounts were inhaled. If swallowed Seek medical attention immediately. All accidents and injuries occurring at work or in the course of employment must be reported to the employee's supervisor as soon as possible (even if no medical attention is required). http://www.ehs.iastate.edu/occupational/accidents-injuries Spill/Release Containment, Decontamination, and Clean Up Procedures: Non-hazardous spills can be cleaned up using the chemical spill kit. In case of a hazardous spill, exit the area immediately and contact the professor in charge to arrange clean up. Using Substances Requiring Special Procedures? No Yes (If Yes; identify authorized personnel, designate a use area and specify specialized safety precautions here. Refer to Section B in the ISU Laboratory Safety Manual for details.) Written By: Date: Approved By: Date: (PI or Lab Supervisor) II. HAZARD ASSESSMENT Use the hierarchy of controls to document the hazards and the corresponding control measure(s) involved in each step of the procedure. Consider elimination or substitution of hazards, if possible. Engineering Control(s): items used to isolate the hazard from the user (i.e. fume hood, biosafety cabinet). Administrative Control(s): policies/programs to limit the exposure to the hazard (i.e. authorizations, designated areas, time restrictions, training). Required PPE: indicate PPE including specific material requirements if applicable (i.e. flame resistant lab coat, type of respirator or cartridge). Hazard Engineering Control(s) III. Administrative Control(s) Required PPE Training Record Use the following table to record the training associated with this Standard Operating Procedure. Print Name Signature Note: Attach to or file with written materials and methods Date