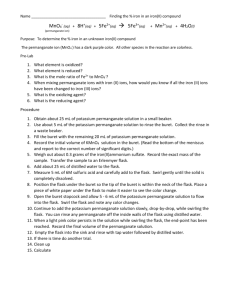

Synthesis of Iron Salt

advertisement

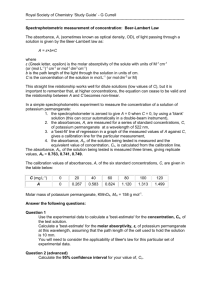

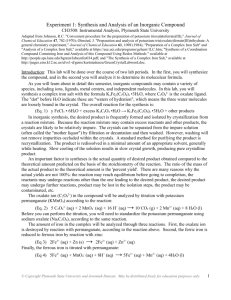

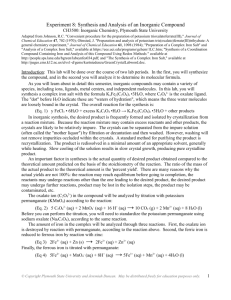

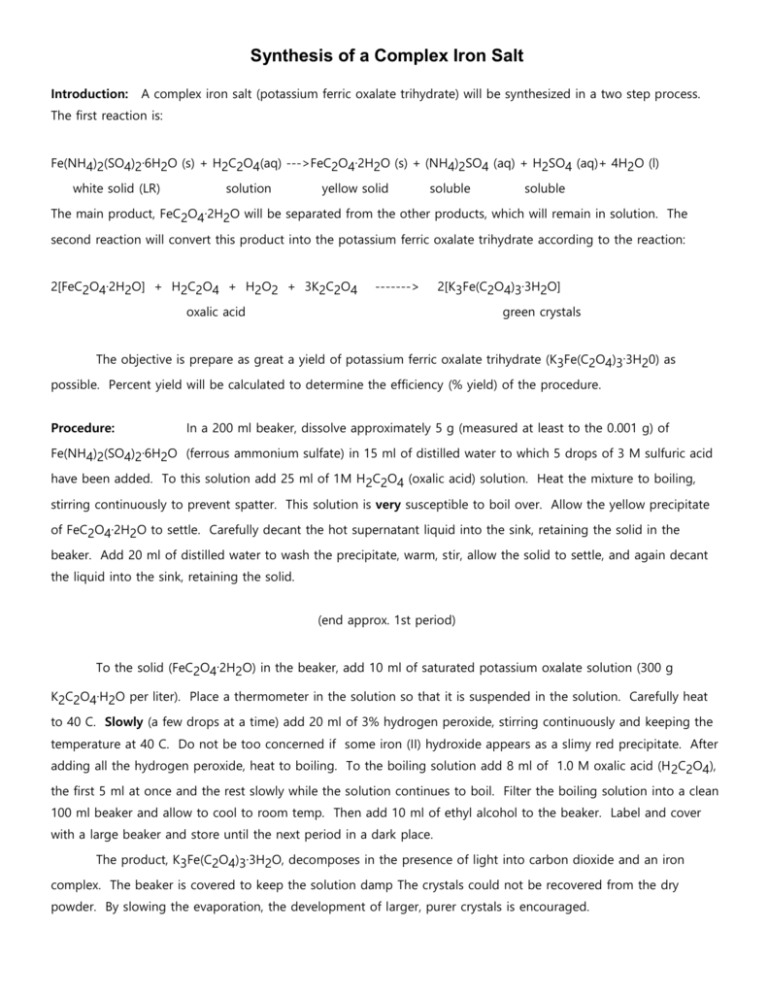

Synthesis of a Complex Iron Salt Introduction: A complex iron salt (potassium ferric oxalate trihydrate) will be synthesized in a two step process. The first reaction is: Fe(NH4)2(SO4)2.6H2O (s) + H2C2O4(aq) --->FeC2O4.2H2O (s) + (NH4)2SO4 (aq) + H2SO4 (aq)+ 4H2O (l) white solid (LR) solution yellow solid soluble soluble The main product, FeC2O4.2H2O will be separated from the other products, which will remain in solution. The second reaction will convert this product into the potassium ferric oxalate trihydrate according to the reaction: 2[FeC2O4.2H2O] + H2C2O4 + H2O2 + 3K2C2O4 -------> 2[K3Fe(C2O4)3.3H2O] oxalic acid green crystals The objective is prepare as great a yield of potassium ferric oxalate trihydrate (K3Fe(C2O4)3.3H20) as possible. Percent yield will be calculated to determine the efficiency (% yield) of the procedure. Procedure: In a 200 ml beaker, dissolve approximately 5 g (measured at least to the 0.001 g) of Fe(NH4)2(SO4)2.6H2O (ferrous ammonium sulfate) in 15 ml of distilled water to which 5 drops of 3 M sulfuric acid have been added. To this solution add 25 ml of 1M H2C2O4 (oxalic acid) solution. Heat the mixture to boiling, stirring continuously to prevent spatter. This solution is very susceptible to boil over. Allow the yellow precipitate of FeC2O4.2H2O to settle. Carefully decant the hot supernatant liquid into the sink, retaining the solid in the beaker. Add 20 ml of distilled water to wash the precipitate, warm, stir, allow the solid to settle, and again decant the liquid into the sink, retaining the solid. (end approx. 1st period) To the solid (FeC2O4.2H2O) in the beaker, add 10 ml of saturated potassium oxalate solution (300 g K2C2O4.H2O per liter). Place a thermometer in the solution so that it is suspended in the solution. Carefully heat to 40 C. Slowly (a few drops at a time) add 20 ml of 3% hydrogen peroxide, stirring continuously and keeping the temperature at 40 C. Do not be too concerned if some iron (II) hydroxide appears as a slimy red precipitate. After adding all the hydrogen peroxide, heat to boiling. To the boiling solution add 8 ml of 1.0 M oxalic acid (H 2C2O4), the first 5 ml at once and the rest slowly while the solution continues to boil. Filter the boiling solution into a clean 100 ml beaker and allow to cool to room temp. Then add 10 ml of ethyl alcohol to the beaker. Label and cover with a large beaker and store until the next period in a dark place. The product, K3Fe(C2O4)3.3H2O, decomposes in the presence of light into carbon dioxide and an iron complex. The beaker is covered to keep the solution damp The crystals could not be recovered from the dry powder. By slowing the evaporation, the development of larger, purer crystals is encouraged. (end approx. 2nd period) Setup a filter and transfer the crystals of K3Fe(C2O4)3.3H2O to the filter paper. Spread the crystals out for drying. When dry, place the crystals into a massed vial and then remass. STANDARDIZING POTASSIUM PERMANGANATE Weigh out about .25 g of dry sodium oxalate into a 250 ml Erlenmeyer flask. In a separate beaker, add 10 ml of concentrated sulfuric acid into 200 ml of distilled water for an approximate .75M solution. Dissolve the sodium oxalate into 75 ml of the sulfuric acid solution. The remainder is saved as a blank. Clean a buret and then rinse three times with 3 - 4 ml of the potassium permanganate. Fill the buret with the permanganate solution. since the color of the solution obscures the buret markings, read from the top of the solution. Heat the sodium oxalate solution to 80 - 90 C and then titrate slowly , constantly swirling. Stop the titration when the first pink color persists in the solution. This will require much swirling. Repeat with the blank and subtract the blank results from the oxalate results. OXALATE ANALYSIS To analyze for the oxalate ion, mass about .2 of a gram of the iron salt and place into a 250 ml Erlenmeyer flask. Dissolve the salt with a few ml of 6M sulfuric acid, then dilute to a total volume of about 75 ml. Heat to 80 C and then titrate with a standardized potassium permanganate solution. Since there are substances that are in the water that may also be oxidized, a blank consisting of the same amount of sulfuric acid and water should also be titrated and that titration volume subtracted from the salt sample results. IRON ANALYSIS Mass about .7 g of the salt and place into a 125 ml Erlenmeyer flask. In the fume hood, add 3 to 6 ml of concentrated sulfuric acid and heat to decompose the salt. All effervescence should cease. Allow the mixture to cool and wash the sides of the flask with 20 ml of distilled water. Heat the resulting solution until the turbidity clears. Add about a teaspoon of zinc amalgam to the resulting iron (III) solution. Heat the solution in a water bath for 20 minutes. Test for completed reduction by removing 1 drop of solution and mixing it with one drop of potassium thiocyanate solution (KSCN) on a watch glass. No immediate coloration indicates that the iron (III) has been completely reduced to iron (II). Cool the flask under the tap, and then plug with glass wool loosely. Decant the solution through the glass wool, collecting the solution in another 250 flask. Wash the amalgam three times with 2 M sulfuric acid, decanting the washings through the plug. Titrate the solution with the standardized potassium permanganate. An alternative method for determining the iron content is to use an ion exchange bed. If this reagent is obtained, specific instructions will be provided. WATER ANALYSIS Mass approximately 1.000 g of substance and place into a clean, dry, and massed evaporating dish. Place the evaporating dish in a drying oven at 110 C for 2 hours and then cool in a dessicator and then remass.

![[Zr(C 2 O 4 ) 4 ] 4](http://s3.studylib.net/store/data/006964769_1-29aedaf41342f4132b60bdeb351827c4-300x300.png)