Industry Basics Specific

advertisement

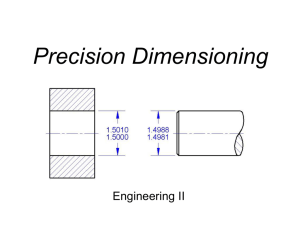

Technical Fundamental Series Industry Basics Specific Courses designed to develop an understanding of the practical and technical skills required by industry. Trainees are taught using the company’s blueprints and gauges. Each course consists of 6 - 12 hours of instruction customized to meet a company’s specific training needs. Industry Math Training focuses on the skills-specific mathematical concepts relative to the industrial work environment. Topics include principles and applications of the following computation skills: addition, subtraction, decimals, multiplication and division; coordinate systems, triangulation; percentages and proportions, percents and decimals, percents of numbers, parts, efficiency and production; metric systems and terminology. Quality Control Training covers inspections, gauge methods and special gauge designs, production gauge, inspections and statistical process control concepts. Upon completion trainees should be able to design and use common gauges and apply statistical process control concepts. Blueprint Reading Training covers the basic principles of blueprint reading taught using actual company blueprints. Training includes: line types, orthographic projections, dimensioning methods, and notes. Upon completion trainees should be able to interpret basic blueprints and visualize the features of a part. Geometric Dimensioning and Tolerance (GD/T) Training introduces the basic geometric dimensioning and tolerance principles taught using on- site company gauges. Topics include: tolerance and quality applications, drawing and tolerance, bilateral and unilateral tolerances and applications, gauging dimensions, symbols and terms, datums, forms and orientation controls, tolerance of position, concentricity, symmetry, runout and profile controls, measurement for quality assurance, measurement with graduated scales and scale instruments, and micrometer instruments, gage blocks, measurement by comparison and tolerance applications. Upon completion, trainee should be able to interpret and apply basic geometric dimensioning and tolerance principles. Safety Training Industrial/Environmental Health & Safety Training introduces principles of environmental health and industrial safety. Emphasis is placed on industry safety, OSHA, and environmental health, safety concepts, regulations and prevention of accidents, injuries, and illnesses. Upon completion trainees should be able to demonstrate knowledge of a safe working environment, basic concepts of environmental health and safety, and OSHA compliance. For additional information contact: Jeff Bright, Assistant to President/Business & Industry Training Services 336-506-4207 jeffrey.bright@alamancecc.edu Sheila Bissette Administrative Assistant 336-506-4151 sheila.bissette@alamancecc.edu