quartz exposed

advertisement

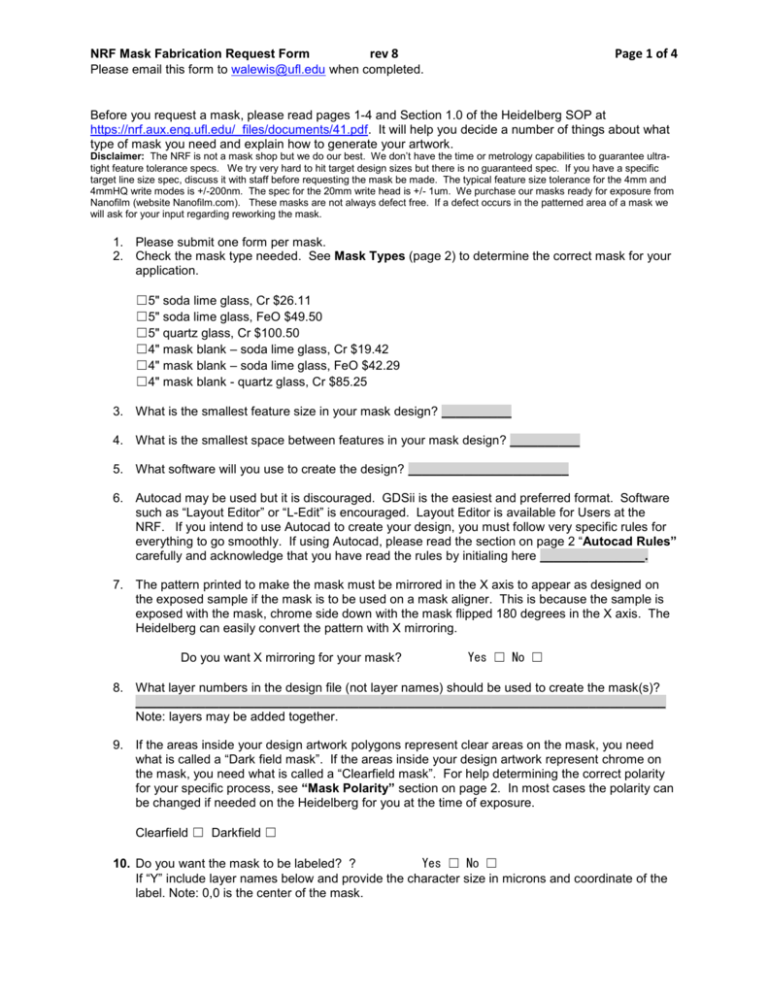

NRF Mask Fabrication Request Form rev 8 Please email this form to walewis@ufl.edu when completed. Page 1 of 4 Before you request a mask, please read pages 1-4 and Section 1.0 of the Heidelberg SOP at https://nrf.aux.eng.ufl.edu/_files/documents/41.pdf. It will help you decide a number of things about what type of mask you need and explain how to generate your artwork. Disclaimer: The NRF is not a mask shop but we do our best. We don’t have the time or metrology capabilities to guarantee ultratight feature tolerance specs. We try very hard to hit target design sizes but there is no guaranteed spec. If you have a specific target line size spec, discuss it with staff before requesting the mask be made. The typical feature size tolerance for the 4mm and 4mmHQ write modes is +/-200nm. The spec for the 20mm write head is +/- 1um. We purchase our masks ready for exposure from Nanofilm (website Nanofilm.com). These masks are not always defect free. If a defect occurs in the patterned area of a mask we will ask for your input regarding reworking the mask. 1. Please submit one form per mask. 2. Check the mask type needed. See Mask Types (page 2) to determine the correct mask for your application. ☐5" soda lime glass, Cr $26.11 ☐5" soda lime glass, FeO $49.50 ☐5" quartz glass, Cr $100.50 ☐4" mask blank – soda lime glass, Cr $19.42 ☐4" mask blank – soda lime glass, FeO $42.29 ☐4" mask blank - quartz glass, Cr $85.25 3. What is the smallest feature size in your mask design? __________ 4. What is the smallest space between features in your mask design? __________ 5. What software will you use to create the design? _______________________ 6. Autocad may be used but it is discouraged. GDSii is the easiest and preferred format. Software such as “Layout Editor” or “L-Edit” is encouraged. Layout Editor is available for Users at the NRF. If you intend to use Autocad to create your design, you must follow very specific rules for everything to go smoothly. If using Autocad, please read the section on page 2 “Autocad Rules” carefully and acknowledge that you have read the rules by initialing here _______________. 7. The pattern printed to make the mask must be mirrored in the X axis to appear as designed on the exposed sample if the mask is to be used on a mask aligner. This is because the sample is exposed with the mask, chrome side down with the mask flipped 180 degrees in the X axis. The Heidelberg can easily convert the pattern with X mirroring. Do you want X mirroring for your mask? Yes ☐ No ☐ 8. What layer numbers in the design file (not layer names) should be used to create the mask(s)? ____________________________________________________________________________ Note: layers may be added together. 9. If the areas inside your design artwork polygons represent clear areas on the mask, you need what is called a “Dark field mask”. If the areas inside your design artwork represent chrome on the mask, you need what is called a “Clearfield mask”. For help determining the correct polarity for your specific process, see “Mask Polarity” section on page 2. In most cases the polarity can be changed if needed on the Heidelberg for you at the time of exposure. Clearfield ☐ Darkfield ☐ 10. Do you want the mask to be labeled? ? Yes ☐ No ☐ If “Y” include layer names below and provide the character size in microns and coordinate of the label. Note: 0,0 is the center of the mask. NRF Mask Fabrication Request Form rev 8 Please email this form to walewis@ufl.edu when completed. Page 2 of 4 Supplemental Information about making masks at the NRF Mask Types 5” glass (sodalime), Cr - most commonly used at the NRF and needed for exposure of entire 4” wafer on NRF mask aligners. Minimum feature size (and space) is ≥2um. Compatible with both NRF mask aligners. Not compatible with Suss MJB3 Aligners used in labs outside of the NRF. 5” glass (sodalime), FeO – same specs as the Cr mask but is transparent to visible light making 2nd layer alignment much easier on the mask aligner. Not usually needed for first layer exposures. Minimum feature size (and space) is ≥3um 5” quartz, Cr – should only be needed if the minumun feature size (or space) is <2um. 4” glass (sodalime), Cr – normally not used unless you are exposing on a Suss MJB3 commonly found in labs outside the NRF. It can be used on the Suss MA6 aligner but NOT on the EVG-620 aligner. 4” quartz, Cr - normally not used unless you are exposing on a Suss MJB3 commonly found in labs outside the NRF. Quartz should only be needed if the minimum feature size (or space) is <2um. It can be used on the Suss MA6 aligner but NOT on the EVG-620 aligner. Mask Polarity The Heidelberg laser exposes the areas inside the artwork or polygons. We use positive photoresist masks at the NRF which means the exposed areas are developed away. These areas are then wet etched away so that those same areas on the mask are then clear glass. Areas not exposed remain chrome (or iron oxide) covered, which block the exposure light during mask aligner exposure. The polarity for a few specific processes are listed below. Plasma or Wet Etch (subtractive)- Darkfield Mask: Subtractive processes require that the photoresist on your device be developed away in the areas that are to be etched away i.e. the “clear/glass” areas of the mask will be etched. Liftoff Process (additive) – Clearfield Mask: Additive processes require that the photoresist on your device remains where you do not want to add material by evaporation, sputter, electroplate etc.. The process requires that the photoresist edge profile be re-entrant which is done by using: A: image reversal of positive photoresist B: negative photoresist In both cases, the artwork/polygons represent the areas where you DO NOT want to add or deposit material. MASK COSTS ESTIMATES Internal Academic Rates Estimate of Mask creation for designs with ≥5um features User Processed Estimate of Mask creation for designs with ≥5um features Staff Processed soda lime mask write time approx 1.5 hour $26 $72 $26 $72 $12.00 soda lime mask write time approx 1.5 hour wet bench processing 30 min wet bench processing 30 min Plus - one time cost of user training on Heidelberg $83 Staff Time $100 $12.00 NRF Mask Fabrication Request Form rev 8 Please email this form to walewis@ufl.edu when completed. Total Cost -1st Mask Total Cost for all subsequent masks $193.11 Total Mask Cost Page 3 of 4 $210.11 $110.11 Pattern edits and troublesome file transfers will be charged separately. * If you know you will only need one mask, it makes sense to have the mask Staff processed. Government labs and UF-Affiliated Companies Estimate of Mask creation for designs with ≥5um features User Processed soda lime mask write time approx 1.5 hour wet bench processing 30 min Plus - one time cost of user training on Heidelberg Total Cost -1st Mask Total Cost for all subsequent masks $18.00 Estimate of Mask creation for designs with ≥5um features Staff Processed soda lime mask write time approx 1.5 hour wet bench processing 30 min $125 $276.61 Staff Time Total Mask Cost $26 $108 $26 $108 $18.00 $75 $227.11 $152.11 Pattern edits and troublesome file transfers will be charged separately. * If you know you will only need one mask, it makes sense to have the mask Staff processed. External Non-Affiliate Rates User Processed soda lime mask write time approx 1.5 hour $25 $144 wet bench processing 30 min $24.00 Staff Processed soda lime mask write time approx 1.5 hour wet bench processing 30 min $25 $144 $24.00 NRF Mask Fabrication Request Form rev 8 Please email this form to walewis@ufl.edu when completed. Plus - one time cost of user training on Heidelberg Total Cost -1st Mask Total Cost for all subsequent masks $200 $393.00 Staff Time 2.5 hours Total Mask Cost $193.00 Pattern edits and troublesome file transfers will be charged separately. * If you know you will only need one mask, it makes sense to have the mask Staff processed. Page 4 of 4 $125 $318.00