08e Reading a Micrometer LP

advertisement

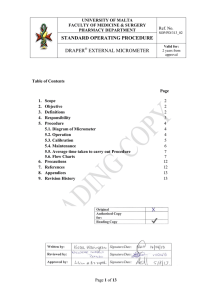

Course Title: Small Engine Technology Lesson Title: Reading and Using the Micrometer TEKS Addressed in Lesson: 130.400 http://ritter.tea.state.tx.us/rules/tac/chapter130/ch130p.html 130.400c8D 130.400c8E The student demonstrates the technical knowledge and skills for small engine technology: The student will identify and safely use small engine measuring tools; and safely use tools used in the operation, maintenance, and repair of two- and four-cycle engines. Lesson Objectives: The student(s) will be able to: 1. 2. 3. 4. Identify the various types of micrometers and their parts; Select the appropriate micrometer as per its size and use; Read and use the micrometer proficiently to measure; and Check tolerances of finished machined parts. Tools and Equipment Dry-erase board or flip chart & markers PowerPoint slides – laptop and LCD projector Computer with Internet access, if available 0 to 1" and 1 to 2" outside micrometer calipers, other types (inside, depth and thread mikes) if possible; several pieces of various ground flat bar and round bar. Teaching Aids: PowerPoint Slides: VI-A-3(PP) Figures 1-7 Information Sheet, VI-A-3(IS) "Reading and Using the Micrometer" Assignment Sheet, VI-A-3(AS) "Reading and Using the Micrometer" Key Terms / Vocabulary Anvil Barrel Caliper Frame Lock nut Micrometer Ratchet stop Spindle Thimble Units Inches Tenths Hundredths Thousandths Ten-thousandths Interest Approach / Anticipatory Set The word "Micrometer" is derived from two Greek words. Micro, meaning small or little, and Meter, meaning a measure. The decimal micrometer is based on the decimal inch, and some read to one tenthousandth of an inch. The most commonly used precision measuring device in industry today (for linear dimensions) is the micrometer which measures accurately to one-thousandth of an inch. This micrometer is used extensively in the mechanical repair industry for measuring and checking tolerance or wear on such things as shaft diameters and other cylindrically machined parts. The decimal micrometer is the most commonly used precision measuring instrument in industry today. The standard micrometer measures accurately to one-thousandth of an inch. The mechanical repair industry has many uses for the micrometer, among which the most prevalent is checking size, tolerance, and wear of closely machined parts such as shafts, cylinders, and bearings. The student of mechanical repair trades must become adept at using the micrometer to fulfill requirements demanded of this industry. Today we are going to learn how to use and read the micrometer. Teaching Plan and Strategy / Presentation of New Material Show Slide Figure #1 1. Present general information about the micrometer. Show Slide Figure #1 2. Discuss the types and sizes of micrometers. 3. Present the parts of outside micrometer. 4. Teach students how to read the micrometer. 5. Explain sequence of reading calibrations. Show Slide Figure #2 Note: Slide will reveal covered readings. Show Slide Figure #3 Note: Slide will reveal covered readings. Show Slide Figure #4 Note: Slide will reveal covered readings. 6. Model using the micrometer properly. Show Slide Figure #5 7. Demonstrate checking for accuracy. 8. Present procedures for care and storage of the micrometer. Activity / Application / Student Engagement / Laboratory Reading Assignment: Information Sheet, VI-A-3(IS) "Reading and Using the Micrometer" Written Assignment: Assignment Sheet, VI-A-3(AS) "Reading and Using the Micrometer" U-shaped crescent 1. The general shape of the frame of outside micrometer calipers is ______. 40 2. The number of threads per inch on the spindle is ______. Decimal inches 3. Micrometers are calibrated to measure in ______. 1/10,000" 4. Vernier mikes will measure accurately to ______. Barrel 5. The longitudinal calibration and index line are located on the ______. T.P.I. 6. Thread mikes range in one inch intervals and by a range of ______. Ratchet 7. The part which prevents the frame from being sprung from undue pressure by the threads is ______. Anvil 8. A hardened button insert at one end of the frame is ______. 1 inch 9. The travel or adjustment of mikes is generally ______. Measure 10. The Greek word "Meter", means ______. 2-3" outside 11. To check a shaft diameter of 2.248" would require a ______ ______ micrometer. 1. Have students list on chalkboard/whiteboard/flip chart points of care and use, and briefly explain why. 2. Class to form small groups and practice miking (measuring) objects supplied by the instructor. Groups write down answers and compare at end of practice. 3. Class to write a short paragraph explaining why micrometer threads are 40 T.P.I. Evaluation / Summary Show Slide Figure #6 Pictorial Recall Test: Parts of Micrometer Caliper 1. 2. 3. 4. 5. 6. 7. 8. Ratchet stop Thimble Barrel Lock nut Frame Spindle Anvil Cut out frame Show Slide Figure #7 Pictorial Recall Test: Reading the Micrometer 1. .400 2. .025 3. .333 4. .555 SUMMARY The word "micrometer" is derived from two Greek words. Micro, meaning small or fine, and Meter, meaning measure. The Micrometer (nickname, mikes) is a precision measuring instrument which measures accurately to a thousandth part of an inch. There are several types; outside, inside, depth and thread mikes, all having the same or similar working parts and are read in a like fashion. Most have one inch of travel or adjustment and come in sizes of one inch increments. The micrometer is composed of a frame (u-shaped on outside mikes) with an anvil at one end and a barrel at the opposite end. The barrel contains internal threads (40 T.P.I.) and outside a longitudinal index line and calibrations. The spindle assembly is composed of the spindle, which has mating threads (40 T.P.I.) to engage with barrel and affect travel of the assembly. The spindle is affixed to the thimble by a thimble cap, which also houses a ratchet stop. The thimble is a hollow tube beveled at the end opposite the cap and calibrated, circularly, in twenty-five equal parts. The assembly travels as a unit by turning the thimble. The micrometer caliper is a precision measuring instrument. The proper use and care of this instrument will insure years of dependable service. Care should be given in handling not to bump or drop the mikes, and in storage to be separated from heavier tools. Measurements should be made with a light touch and each measurement double checked for accuracy and reading. In reading the mikes, each large longitudinal calibration on the barrel is 1/10" or .100" - read only those completely visible. To this, add each small longitudinal calibration which equals 1/40" or .025" - again, read only those completely visible. Last, read the circular calibration on the barrel nearest the index line and the total of the reading will result in the nearest decimal fraction of an inch of the object being measured. References / Additional Materials / Extended Learning Opportunities / Enrichment https://www.google.com/search?q=micrometer&client=firefox-a&rls=org.mozilla:enUS:official&channel=sb&biw=1233&bih=724&tbm=isch&tbo=u&source=univ&sa=X&ei=o1JJVJ_MN8HpggTC 04DQCg&sqi=2&ved=0CEYQsAQ http://www.youtube.com/watch?v=i_jygJkJujE http://www.grainger.com/category/micrometers/measuring-and-layout-tools/hand-tools/ecatalog/N-961 http://www.wikihow.com/Use-and-Read-an-Outside-Micrometer College & Career Readiness Standards: http://www.thecb.state.tx.us/collegereadiness/crs.pdf ENGLISH/LANGUAGE ARTS STANDARDS I. Writing – A 1 2 3 4 5 II. Reading – A 1 2 3 4 5 B 1 III. Speaking –B 1 2 IV. Listening – A 1 2 3 B 1 2 3 MATHEMATICS STANDARDS I. Numeric Reasoning – A 1 2 B 1 C 1 II. Algebraic Reasoning – A 1 B 1 C 1 IV. Measurement Reasoning – A 1 B 1 2 VIII. Problem Solving and Reasoning – A 1 2 3 4 5 IX. Communication and Representation – A 1 2 3 C 1 2 3 X. Connections – A 1 2 B 1 2 3 CROSS-DISCIPLINARY STANDARDS I. Key Cognitive Skills –C 1 2 3 D 1 2 3 4 E 1 2 Revised by: CDC Custom Development Co., LLC for Texas A&M University. Copyright © 2014 Texas Education Agency