Chapter 32: Hazardous Materials: Operations and Specialties

advertisement

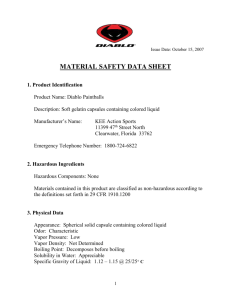

Fundamentals of Fire Fighter Skills, Canadian Third Edition Chapter 32: Hazardous Materials: Operations and Specialties Chief Concepts To ensure your safety and that of your crew, you must be able to recognize a potential hazardous material as soon as possible. Hazardous materials incidents can occur almost anywhere. Hazardous materials are stored in warehouses, hospitals, laboratories, industrial occupancies, residential garages, bowling alleys, home-improvement centres, garden supply stores, restaurants, and many other businesses. A container is any vessel or receptacle that holds material, including storage vessels, pipelines, and packaging. Often the container type, size, and material provide important clues about the nature of the substance inside. Bulk storage containers include the following types: • Fixed tanks—Include vertical storage tanks, above ground storage tanks, and underground storage tanks. Often these containers are surrounded by a supplementary containment system to help control an accidental release. • Large transportation tankers—Used to transport hazardous materials. • Totes—Portable plastic tanks surrounded by a stainless-steel web that adds both structural stability and protection. Both shipping and storing totes can be hazardous operations. • Intermodal tanks—Used as both shipping and storage vehicles. They hold between 18,925 and 22,710 L (5000 and 6000 gal.) of product and can be either pressurized or nonpressurized. Bulk storage containers, or large-volume containers, are defined by their internal capacity based on the following measures: • Liquids—More than 450 L (119 gal.) • Solids—More than 400 kg (882 lb.) • Gases—More than 400 kg (882 lb.) Nonbulk storage vessels include the following types: • Drums—Barrel-like containers used to store a wide variety of substances. • Bags—Commonly used to store solids and powders. Pesticide bags must be labelled with specific information. • Carboys—A glass, plastic, or steel container that holds 19–57 L (5–15 gal.) of product, such as some corrosives and other types of chemicals. • Compressed gas cylinders—Used to hold liquids and gases. • Cryogenic containers—Include dewar containers that hold gaseous substances that have been chilled until they liquefy. Chemical transport vehicles or tankers include the following types: • TC306/MC306/DOT406 flammable liquid tanker— Typically carries gasoline or other flammable and combustible materials. • TC307/MC307/DOT407 chemical hauler—Round or horseshoe-shaped tank that typically carries 22,712 to 26,498 litres (6000 to 7000 gallons) of flammable liquids, mild corrosives, and poisons. 1 Copyright © 2014 Jones & Bartlett Learning, LLC, an Ascend Learning Company and the National Fire Protection Association® Fundamentals of Fire Fighter Skills, Canadian Third Edition • MC312/DOT412 corrosives tanker—Used to transport concentrated sulfuric and nitric acids and other corrosive substances. • TC331/MC331 pressure cargo tanker—Carries materials such as ammonia, propane, and butane. • TC341/CGA341/MC338 cryogenic tanker—Low-pressure tanker that relies on tank insulation to maintain low temperatures to transport cryogenic gases. • Tube trailers—Carry compressed gases, such as hydrogen, oxygen, helium, and methane. • Dry bulk cargo tanks—Commonly seen on the road and carry dry bulk goods, such as powders, pellets, fertilizers, and grain. Railway tank cars can carry volumes up to 113,550 L (30,000 gal.) and have the potential to create large leaks or vapour clouds. There are three basic railcar configurations: • DOT-111 nonpressurized railcars—Carry general industrial chemicals, consumer products, flammable and combustible liquids, and mild corrosives. • DOT-105 and DOT 112 pressurized railcars— Transport materials such as propane, ammonia, ethylene oxide, and chlorine. • Special-use railcars—Include boxcars, flatcars, corrosive tank cars, and highpressure compressed gas tube cars. Pipelines often transport hazardous materials. They may be located either underground or above ground. Additional reference sources for hazardous materials include SDSs, shipping papers, and staffed national resources such as CANUTEC and CHEMTREC ® . Industries that routinely use radioactive materials include food testing labs, hospitals, medical research centres, biotechnology facilities, construction sites, and medical laboratories. Radioactive materials are not detected by sight, smell, taste, or other senses. If you have any suspicion that the incident involves radiation, it will be necessary to call a hazardous materials team or some other resource with radiation-detection capabilities. After identifying that a hazardous material is present, you must identify the resources needed to properly respond to the incident. The resources sought for a hazardous materials incident should include support personnel, trained hazardous materials technicians, and technical specialists who will help identify the hazardous material and control the incident. Additional calls should then request decontamination personnel and equipment. Other notifications could include the CANUTEC (or CHEMTREC ® , where applicable), local and provincial/territorial environmental agencies, and the local emergency planning commission. A predetermined list of contact names, agencies, and numbers should be established and maintained at the dispatch centre. No offensive action should be taken until the hazardous material has been properly identified. After the material is identified, an operations-level responder should perform only actions that do not involve contact with the material. The responder must use full PPE during any activity and must complete decontamination procedures prior to leaving any area where the hazardous material is present. When reporting the hazardous material incident, if possible, provide all of the following information: 2 Copyright © 2014 Jones & Bartlett Learning, LLC, an Ascend Learning Company and the National Fire Protection Association® Fundamentals of Fire Fighter Skills, Canadian Third Edition • • • • The exact address and specific location of the leak or spill Identification of indicators and markers of hazardous materials All colour or class information obtained from placards Four-digit United Nations (UN)/North American (NA) identification numbers for the hazardous materials • Hazardous material identification obtained from shipping papers or SDS and the potential quantities of hazardous materials involved • Description of the container, including its size, capacity, type, and shape • The amount of chemical that could leak and the amount that has already leaked • Exposures of people and the presence of special populations (e.g., children or elderly) • The environment in the immediate area • Current weather conditions, including wind direction and speed • A contact or callback number and two-way radio frequency or channel The highest priority of an IAP is to consider the safety of the responding personnel. Responders are there to isolate, contain, and remedy the problem—not to become a part of it. Sometimes no action is the safest course of action. At the operational level, all response objectives should be primarily defensive (i.e., personnel do not come in contact with the hazardous material). Defensive objectives do not involve stopping the leak or release of a hazardous material and include the following: • Isolating the area affected by the leak or spill and evacuating victims who could become exposed to the hazardous material if the leak or spill were to progress • Controlling where the spill or release is spreading • Containing the spill to a specific area • Diking and damming • Absorbing/adsorbing the hazardous material • Stopping the flow remotely • Diluting or diverting the material • Suppressing or dispersing vapour Terrorists who want to injure responding personnel with a secondary device or attack will typically make the initial attack very dramatic to draw responders into very close proximity to the scene. As responders begin to treat victims, the secondary attack then takes place. • Signs of secondary devices may include tripwires, timers, and ordinary, everyday containers (e.g., luggage, briefcases, boxes) found in very close proximity to the initial incident site. • The smell of chemicals or the sighting of chemical dispersion devices or other containers that may hold chemical, biological, or even radioactive agents could be an indicator that a secondary attack is possible. The IMS can be expanded to handle a hazardous materials incident. A special technical group may be developed under the operations section known as the hazardous materials branch. 3 Copyright © 2014 Jones & Bartlett Learning, LLC, an Ascend Learning Company and the National Fire Protection Association® Fundamentals of Fire Fighter Skills, Canadian Third Edition Temperature-related conditions and stress pose dangers. If the body cannot disperse heat because it is covered by a closed, impermeable garment, serious short- and long-term medical situations could result. These medical conditions include the following: • Heat exhaustion—: Mild form of shock that occurs when the body overheats. • Heatstroke—Potentially fatal condition of which the reduction or cessation of sweating is the first symptom. Immediate medical attention is required. To avoid cold-related injuries, such as frostbite, fire fighters should dress in layers and try to keep dry. The control zones at a hazardous materials incident are as follows: • Hot zone—Area immediately around the incident. Only properly trained and equipped personnel should enter this zone. • Warm zone—Contains the decontamination corridor. • Cold zone—No special PPE is required. This zone contains the ICP, personnel staging area, and rehabilitation area. Team members should always remain within sight, sound, or touch of each other. Responders are required to take appropriate steps to monitor the atmosphere for potential hazards. Monitoring priorities should include radiation, corrosive vapours, oxygen levels, combustibility, and final toxicity. Radiation monitoring is conducted using a Geiger counter. Oxygen levels and combustible levels are typically monitored with the use of a two-, three-, four-, or five-gas monitor. Other specialized chemical monitors can be used to detect individual chemicals. The search and rescue process is more complicated in a hazardous materials incident than in a structure fire. Before beginning search and rescue operations, all emergency response personnel must first recognize and identify when hazardous materials may be present. After this is accomplished, the IC must evaluate the conditions. If hazardous materials are present, the IC must determine whether hazardous materials technicians can safely enter the hot zone to perform search and rescue operations. Decontamination makes personnel, equipment, and supplies safe by removing or reducing hazardous materials or WMDs. Proper decontamination is essential at every hazardous material/WMD incident to ensure the safety of both personnel and property. Cross-contamination is the process by which a contaminant is carried out of the hot zone and contaminates people, animals, the environment, or equipment. Cross-contamination may occur in several ways: • A contaminated victim comes into physical contact with an emergency responder. • A bystander or other emergency responder comes into contact with a contaminated object from the hot zone. • A decontaminated responder comes into contact with another contaminated responder or object. Fire fighters are often responsible for establishing a decontamination corridor. There are four major categories of decontamination: • Emergency decontamination—Aims to reduce the amount of surface contaminant. Involves dousing the victim with water via a hose line outside of a decontamination corridor. Formal decontamination is performed later. 4 Copyright © 2014 Jones & Bartlett Learning, LLC, an Ascend Learning Company and the National Fire Protection Association® Fundamentals of Fire Fighter Skills, Canadian Third Edition • Gross decontamination—Uses a large shower system in a decontamination corridor. This type of decontamination is used for a brief and rapid contamination reduction. • Technical decontamination—Performed after gross decontamination and may involve several steps. • Mass decontamination—Used to decontaminate large groups of people in the field. Victims will need to undergo further and more thorough decontamination. Alternative decontamination procedures include the following options: • Absorption—Use of a spongy material to soak up the hazardous material. This technique is used to decontaminate equipment and property. • Adsorption—Binding of the contaminant to the surface of an added material, which is then disposed of. • Dilution—Use of soap and water to flush the hazardous material off a person or object. • Disinfection—Process used to destroy disease-carrying organisms. • Disposal—Two-step removal process for items that cannot be decontaminated properly. • Solidification—Chemical process of treating a hazardous liquid to become a solid. • Emulsification—Process of neutralizing or reducing the harmful effects of a hazardous material by changing its chemical properties. • Vapour dispersion—Process of separating and diminishing harmful vapours, often with a water spray. • Removal—Process of removing contaminated soil from a hazardous materials site. • Vacuuming—Removal of dusts, particles, and liquids by sucking them into a container. • Decontamination process—The decontamination process takes place in the decontamination corridor between the hot zone and the warm zone. Within this corridor, fire fighters pass through several stations to complete the decontamination process. After all of the factors have been considered, the IC may decide that the hazardous materials incident cannot be handled without unnecessary risks and that all personnel should withdraw. The recovery phase of a hazardous materials incident occurs when the imminent danger to people, property, and the environment has passed or is controlled and clean-up begins. During this phase, state and federal agencies may become involved in cleaning up the site, determining the responsible party, and implementing cost-recovery methods. The recovery phase in large-scale incidents can last for days, weeks, or even months and may require resources and equipment beyond those available to local responders. If a hazardous materials incident involves potential criminal or terrorist activity, responders must notify law enforcement and appropriate federal agencies. Specific activities should be implemented to ensure safety, such as isolating the scene. 5 Copyright © 2014 Jones & Bartlett Learning, LLC, an Ascend Learning Company and the National Fire Protection Association®