No08-ContainmentofHazardousSpills

advertisement

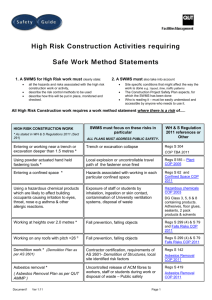

Code of Practice COP 8 Issued Nov 99, Revised August 10 No 8 – CONTAINMENT OF HAZARDOUS SPILLS 1. BACKGROUND TO COP Reason for COP: To prevent injury and damage to plant when dealing with a hazardous spill. To contain and clean up any hazardous leaks and spills. Relevant Regulations: Employee Training/Skills Reqd: All employees likely to encounter such an event shall be trained in proper response procedures. Purchasing Policy Tools/Plant: Each depot will maintain sufficient mop up and containment gear for minor event. Spills requiring specialist equipment or breathing apparatus to be dealt with by trained or specialist staff (Fire Brigade) Dangerous Goods Act. Resource Management Act. Haz chem handling instructions. 2. COP WORK PROCEDURE 1. Move away quickly to a safe distance; turn off ignition sources if you can. 2. Seal off the area, but do not go downwind of the spill particularly if you are unsure of material spilled. Protect waterways with bunds or cut-off drains. 3. Look for injuries, if you find a victim; get them to fresh air, only if you can enter safely without breathing apparatus. 4. Identify what you saw, and don’t go back. Pay particular attention to any Haz chem labelling. 5. Promptly access the material safety data sheet to determine the action to be taken. If you must check the material, use the buddy system, never go alone or contact Council’s pollution team. 6. Get help, nobody should clean up alone. Phone the Council’s pollution team and inform management. If not available phone 111 and ask for the fire service. 7. If the victim has come in contact with a hazard, remove affected clothing and flush the affected area with running water until instructed to stop by an expert. Keep victims warm and call for medical support. 8. Contain the spill, stop the source and stop the spread. Do NOT go down wind if unsure of contaminant. 9. When cleaning up the spill, wear the maximum protection possible; be sure to have the right protection for the situation at hand. Don’t touch, taste, breathe in, smoke or make sparks. Document1 Page 1of 2 Hazard Identification & Analysis Worksheet – HBRC Work Task, Activity or Item of Equipment What can cause harm? How could potential harm situation arise? Significant Hazard Yes/No* Controls that Reduce Harm 08 – Containment of Hazardous Spills Performing job/ general duties Limb injury from slip, trip or fall Burns Document1 Date: August 2010 Incorrect PPE Uneven or unsteady ground Carrying excessive loads Y M I Ref COP 00 – Generic Fieldworker Operations Minimum PPE – Overalls, gloves, gumboots and eye protection. Depending on substance, additional specialist PPE may be required. If not sure ask. If not experienced or trained, stay outside of cordon. Obtain MSDS sheets Maintain cordon area. Minim PPE – Overalls, gloves, gumboots with tread and eye protection Clear site of debris Cordon spilled areas Fire or explosion Y M I Minimum PPE Establish cordon for no naked flames Elevate control to specialist fire-fighters Working outside generic hazards Skin irritations or Incorrect or no PPE chemical burns Inexperienced with product Working in wrong area Status Y M In place In place In Place In Place In place In place In place Senior operator monitoring operation and training. In place In Place In Place Page 2of 2