Supplementary information - Springer Static Content Server

advertisement

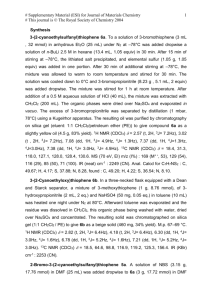

Supplementary information: Synthesis and Characterisation of 1-MPA-MG All 1H and 13C NMR spectra were recorded on a Bruker Avance 400 MHz NMR spectrometer. Data acquisition and processing was managed using Topspin/ICONNMR NMR software package and plotting was managed using MestReC v 4.9.9.9. All chemical shifts for 1H NMR were measured in parts per million (ppm) referenced to an internal standard of residual proteosolvent, δ 7.26 ppm for chloroform. All spectra were run in deuterochloroform, unless otherwise stated. All C NMR were measured in ppm referenced to the solvent signal at δ 77.16 ppm. Spectroscopic 13 resonances were assigned using the following abbreviations: s, singlet; d, doublet; t, triplet; q, quartet; m, multiplet. High Resolution Mass Spectrometry analyses were collected on a Waters Micromass LCT Premier XE time-of-flight mass spectrometer fitted with an electrospray (ESI) ion source and controlled with MassLynx software version 4.5. Low Resolution Mass spectrometry analyses were performed using a Shimadzu single quadrupole mass spectrometer equipped with an atmospheric pressure (ESI) ion source. Sample management was facilitated by Shimadzu LCMS solution and the instrument was controlled by a Shimadzu CBM-20A system controller using LCMS solutions software (Shimadzu Scientific Instruments, Kyoto, Japan). Purity of the final prodrugs were determined to be >95% by analytical High Performance Liquid Chromatography (HPLC) measurements carried out on a Shimadzu CBM-20A system controller which relayed information between the instrument and LCMS workstation. Samples were injected into a Phenomenex Gemini C18 110A column (3 μm particle size, 50 mm × 2.00 mm i.d. Phenomenex, CA) held at 40 ºC in a CTO-20A column oven. A flow rate of 0.4 mL/min was maintained by LC20AD pumps (Shimadzu, Kyoto, Japan) and mobile phase preserved in a degassed state using an inline DGU-20A5 solvent degasser (Shimadzu). Samples were run over a gradient of 80% – 100% Buffer B. Buffer A (95% H2O: 5% CH3CN, 2 mmol/L CH3COONH4, 0.1% HCO2H), Buffer B 1 (95% CH3CN: 5% H2O, 2 mmol/L CH3COONH4, 0.1% HCO2H). Thin layer chromatography (TLC) was performed on Merck Silica Gel 60 F254 plates. TLC plates were visualised under UV light at 254 nm and/or with the aid of vanillin, potassium permanganate, p-anisaldehyde or phosphomolybdic acid (PMA). Preparative TLC was performed on Analtech silica gel GF F254 plates 20 × 20 cm, 500 microns. Column chromatography was achieved using Davisil silica gel LC60A (40-63 micron). All commercially available chemicals were purchased from Aldrich/Fluka or GL Biochem (Shanghai), stored appropriately and used as required. Hexane and ethyl acetate were distilled before use. HPLC-grade CH2Cl2, THF and DMF were dried using MBraun solvent purification system (SPS-800) according to manufacturer’s instructions. All other solvents were reagent grade and used as required. (E)-(2,2-Dimethyl-1,3-dioxolan-4-yl) methyl 6-(4-hydroxy-6-methoxy-7-methyl-3-oxo-1,3dihydroisobenzofuran-5-yl)-4-methylhex-4-enoate (12) Thionyl chloride (100 L, 1.37 mmol) and DMF (2 L) was added to a solution of mycophenolic acid (1), 100 mg, 0.312 mmol) in CH2Cl2 (4 mL) and the mixture was stirred at rt under N2 for six hours. The solution was concentrated under reduced pressure to give the crude acid chloride, which was re-dissolved in CH2Cl2 (3 mL). Pyridine (100 L, 1.29 mmol) and a solution of solketal (10) (61.9 mg, 0.468 mmol) in CH2Cl2 (1 mL) were added dropwise and the reaction stirred 2 at rt for 17 hours. The reaction mixture was diluted with CH2Cl2 and quenched with water. The organic phase was washed with 0.5 M HCl, water, sat. aq. NaHCO3 and brine, dried (MgSO4) and concentrated under reduced pressure to give the crude product. Silica gel chromatography (20% to 25% EtOAc/hexanes) gave ester 12 (40.9 mg, 30%) as a colourless oil. 1 H NMR (400 MHz, CDCl3): 7.69 (br s, 1H), 5.22 (td, J = 6.9, 1.1 Hz, 1H), 5.18 (s, 2H), 4.25 (m, 1H), 4.12-3.98 (m, 3H), 3.75 (s, 3H), 3.68 (dd, J = 8.4, 6.1 Hz, 1H), 3.37 (d, J = 6.9 Hz, 2H), 2.47-2.40 (m, 2H), 2.33-2.26 (m, 2H), 2.13 (s, 3H), 1.78 (s, 3H), 1.40 (s, 3H), 1.34 (s, 3H). C NMR (100 MHz, CDCl3): 173.2, 173.0, 163.8, 153.7, 144.2, 134.1, 122.9, 122.2, 116.8, 13 109.9, 106.5, 73.7, 70.1, 66.5, 64.7, 61.1, 34.6, 32.9, 26.8, 25.5, 22.7, 16.2, 11.7. ESI-HRMS: calcd. for C23H30NaO8 [M + Na+] 457.1833; found 457.1834. (E)-2,3-Dihydroxypropyl 6-(4-hydroxy-6-methoxy-7-methyl-3-oxo-1,3-dihydroisobenzofuran5-yl)-4-methylhex-4-enoate (6) p-TsOH•H2O (1.6 mg, 8.5 mol) was added to a solution of acetonide 12 (18.4 mg, 42.3 mol) in CH2Cl2 (1.5 mL) at 0 °C and the mixture was stirred at 0 °C for two hours and then at rt for four hours. Et3N (2 drops) was added and the reaction stirred for five minutes, and then concentrated under reduced pressure to give the crude product. Silica gel chromatography (80% EtOAc/hexanes) gave diol 6 (11.9 mg, 71%) as a colourless oil. 1 H NMR (400 MHz, CDCl3): 7.76 (br s, 1H), 5.23 (m, 1H), 5.19 (s, 2H), 4.14 (dd, J = 11.6, 4.7 Hz, 1H), 4.08 (dd, J = 11.6, 6.1 Hz, 1H), 3.87 (m, 1H), 3.76 (s, 3H), 3.65 (dd, J = 11.4, 4.0 Hz, 1H), 3.56 (dd, J = 11.4, 5.8 Hz, 1H), 3.38 (d, J = 6.9 Hz, 2H), 2.47 (dt, J = 14.3, 5.3 Hz, 2H), 2.32 (t, J = 7.4 Hz, 2H), 2.15 (s, 3H), 1.80 (s, 3H). 3 C NMR (100 MHz, CDCl3): 173.8, 173.1, 163.7, 153.8, 144.3, 134.1, 123.0, 122.3, 116.9, 13 106.6, 70.3, 70.2, 65.3, 63.5, 61.2, 34.6, 32.9, 22.8, 16.3, 11.7. ESI-HRMS: calcd. for C20H26NaO8 [M + Na+] 417.1520; found 417.1515. Sample preparation and HPLC-MS analysis Preparation of lymph and plasma samples Analysis of the concentration of MPA and prodrug derivatives in lymph samples, and analysis of MPA concentration in plasma samples collected during in vivo lymphatic transport studies were conducted as described previously [1]. Analysis of the prodrug derivatives in plasma samples was conducted using a hydrolysis method similar to the method described in [1] with slight modifications. Briefly, after addition of 10 µl of internal standard (ketoprofen 6 µg/ml in 1:1 (v/v) ACN:water) to 100 µl of plasma, hydrolysis of potential glyceride derivatives of MPA was achieved via addition of 140 µl 0.5 M NaOH in a 1:1 (v/v) ethanol:water and heating in an oven at 80 °C for 5 min. Subsequently, 70 µl of 1 M HCl aqueous solution was added to each sample to stop the hydrolysis. After vortexing for 0.5 min, the sample was diluted with 1 ml mobile phase (2 mM ammonium formate, 0.1% formic acid in ACN:water-82:18, v/v). After vortexing for 1 min, each sample was centrifuged at 4500 g for 5 min and 150 µl of supernatant analysed for total MPA by HPLC-MS. HPLC-MS analysis A Shimadzu LC-MS 2010 system was used as described previously [1]. Specific HPLC-MS conditions for the analysis of MPA, ketoprofen (internal standard), 2-MPA-TG and metabolic products of the prodrug are listed in Table 1. 4 Table 1. HPLC-MS conditions for analysis of MPA and prodrugs MPA, ketoprofen, 1- or 2- MPA-MG** 2-MPA-DG*, 2-MPA-TG and potential glyceride derivatives in lymph HPLC Column Luna C8 100A column (5 µm particle size, 150 mm × 4.60 mm i.d. Phenomenex, CA, USA) Proto 300 C4 300A column (5 µm particle size, 100 mm× 4.6 mm i.d., Higgins Analytical Inc, CA, USA) Mobile phase 82:18 (v/v) ACN-water with 2 mM ammonium formate, 0.1% formic acid and 0.1 mM HCl Flow rate 0.4 ml/min isocratic Retention time (min) 4.6 for MPA, 4.9 for ketoprofen 4.3 for 1- or 2- MPA-MG 8.3 for 2-MPA-DG, 11.6 for 2-MPA-TG m/z ion (+) peak for detection 320.95 for MPA [M+H]+ 254.95 for ketoprofen [M+H]+ 394.95 for 1- and 2- MPA-MG** [M+H]+ 633.20, 650.20, 655.20 for 2-MPA-DG*; 888.35 for 2-MPA-TG [M+NH4]+ Mobile phase A was 5:95 (v/v) ACN-water with 0.1% formic acid and mobile phase B (MPB) was 95:5 (v/v) ACN-water with 0.1% formic acid 0.4 ml/min gradient, sequence of MPB (v/v): 0-0.1min 50 % 0.1-3min 50-100% 3-12.5min 100% 12.5-13min 100-50% 13-19min 50% * 2-MPA-DG is a proposed intermediate metabolite of 2-MPA-TG that is described in Error! Reference source not found. and Error! Reference source not found. in the main manuscript and is produced via lipolysis of the TG prodrug at position sn-1 or 3 of the glycerol backbone. A standard of 2-MPA-DG could not be isolated due to instability during synthesis and upon storage. However, the presence of positive ions at m/z 633.20, 650.20 and 655.20 are consistent with the proton adduct [2-MPA-DG + H]+, ammonium adduct [2-MPA-DG + NH4]+ and sodium adduct [2-MPA-DG + Na]+, respectively. Furthermore, the initial increase and subsequent decrease of this signal, in parallel with disappearance of 2-MPA-TG and gradual generation of 2-MPA-MG and MPA, during in vitro hydrolysis of 2MPA-TG in the presence of 20 µM orlistat (Error! Reference source not found. in the main manuscript), strongly support that the signals with retention time of 8.3 min are 2-MPA-DG. ** Similarly, 2-MPA-MG is also a potential metabolite of 2-MPA-TG described in in Error! Reference source not found. and Error! Reference source not found. in the main manuscript. An authentic standard compound of 2-MPA-MG was not isolated due to instability during synthesis and upon storage and the isomer 1-MPA-MG was therefore synthesised to use as a standard to allow better quantification of the isomer 2-MPA-MG by HPLC-MS. Positive ions at m/z 394.95 is consistent with the proton adduct [1- or 2- MPA-MG + H]+. 5 References 1. Han, S., et al., Targeted delivery of a model immunomodulator to the lymphatic system: Comparison of alkyl ester versus triglyceride mimetic lipid prodrug strategies. J Control Release, 2014. 177: p. 1-10. 6