PM Beck Automation (CH)

advertisement

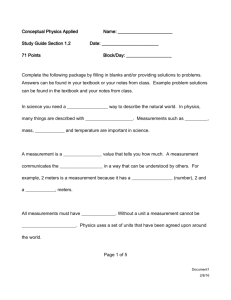

____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa █ K 2013: IML Technology For Food And Non-Food Applications IML Experts Give New Impulses at K 2013 IML Competence in the Reference Class: "Make It Simple, fast, and Proven“ The IML Competence collaboration of IML experts involving Beck Automation AG, Ernst H. Furrer AG, Glaroform AG, Viappiani Printing and BFA Solutions Ltd. demonstrates the possibilities of a high-performance system for IML technology (In-Mold Labeling) at K 2013. Visitors benefit from the full expertise that this collaboration brings to the table, from the injection mold and automation to labeling through to the final product. IML Competence stands for the high quality and exacting standards we have come to expect. K 2013 will see new impulses on simplified operation, QA measures, and documentation options for IML in food and non-food applications. The presentation showcases the entire IML range as a reference manufacturing cell. The long-standing IML Competence partnership permits high availability and top class performance for manufacturers while being easy to operate and offers new QA measures and documentation on how to improve the added value of new systems. PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 1 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa IML Technology to Order: Every Component Counts As IML is a highly dynamic process, profitability is derived from the level of system components. Electrostatic charging and core alignment are the key processing points in the procedure. First the labels are sucked from the label magazine. In the second, the labels are placed on the cores and held with vacuum. The automation cores move into the cavities to transfer the labels. In this stage the labels are blown against the vacuum, electrostatically charged and thus placed and held in the cavities so they are form-fitting. This makes the level of process design and quality of the label key factors in process safety, reproducibility, product quality and economic efficiency. „Swiss-Made” Mold Technology for Thin-Wall Technology Glaroform AG in Näfels, Switzerland, shows a fast running injection mold with 2 cavities for a round-oval 500 ml food container. The mold has an on-site hot runner system with pneumatically operated needle valves. The molded part is decorated with IML on the sides. The mold is equipped with a form-fitting and highly efficient cooling system, in order to guarantee a very fast cycle time with reproducible product quality. Form-fitting cooling also effectively reduces warping of the part. The mold satisfies the latest standards in design engineering, and is made from pure quality tool steel. To ensure the long period of application for molds for which Glaroform is renowned, the mold is manufactured using the latest surface coating processes for excellent process safety, and with the utmost precision in tight tolerances. The thin-walled product has an average wall-thickness of 0.4 mm and a weight per unit of approx. 11 g. PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 2 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa Highly Effective and Easy To Use: Automation with QA Module Beck Automation AG in Oberengstringen, Switzerland, adds a highly dynamic automated IML system to the manufacturing cell. The modular cell raises the bar in speed, availability and process reliability in IML automation. The application cycle time is less than 3.0 seconds. Beck's system is equipped with the latest in control and drive technology. It is operated by touch screen. An integrated remote access provides the option to log into the system from outside in order to provide cost-efficient and fast customer assistance when required. With this approach, Beck Automation has taken its systems' user-friendliness to a new level. A camera inspection system from Omron is used for quality control of the manufactured containers. Any parts determined to be flawed are rejected by the Q-SORT LINE after inspection, and collected in a NOK parts box. The good products are then stacked and removed from the system via a conveyor belt. The Q-SORT LINE can be retrofitted: Existing plants can be upgraded with this QA module. This separation of OK/NOK units in a highly dynamic system provides a manufacturer with a completely new level of assistance to ensure that quality assurance standards are satisfied. Energy-Efficient Cooling Concepts The renowned company Ernst H. Furrer AG in Dällikon, Switzerland, supports the application with temperate cooling water using the newest cooler technology. So-called "free cooling" can be deployed optionally. This means that cooling is achieved with cold outside air, as long as the difference is sufficient to permit the desired medium PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 3 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa temperature. The use of compressors is unnecessary in this phase, enabling power cost savings of up to 60%. Accentuate Product Communication with High-Quality Labels Viappiani Printing in Segrate, Italy, produces labels for this exhibit based on a 60µ EUP orange peel film made by Treofan. The container's round-oval shape requires labels to be stamped with the utmost precision and that can guarantee the fast cycle time with a good electrostatic charge. The sheet offset method guarantees the best print quality for both the 4-color photographs and the Pantone colors. Viappiani can print IML labels with up to 8 colors including lacquer coating. This gives users a broad range of options to lend their products an upmarket look and feel and accentuate them at the point of sale. Spotlight Shines on Complete Documentation in IML BFA Solutions Ltd. for the first time ever presents the production data capture for a closed cell (MDE) in packaging for IML Competence. The product information system PiSolutions jointly captures, displays and chronologically logs the process data, data sets, orders, error messages and status information of the exhibited application. This is a forward-looking step toward Industry 4.0 and complete data recording of a variety of components with different controllers. In the case of the exhibited application, the injection molding machine data is recorded by the machine's standardized Euromap63 interface and combined with the automation data received from an OPC interface. This data is then stored and visualized in a central database. This is made possible by the newly created combination of the bundled solutions Pi_Inject and Pi_Assembly, each of PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 4 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa which include the industry-specific features of MES PiSolutions, thereby ensuring a swift and smooth transition from injection molding and automation. This type of data capturing supersedes the installation of several independent BDE/MDE systems within a production environment and can be used as a single, central module which can be linked to a master ERP system. Publication free of charge – specimen copy requested Captions █████████████████████████████████████████ CAP 0 (lead picture): Thin-wall technology molding for IML: Dual-cavity high-performance mold by Glaroform CAP 1: Q-SORT LINE OK/NOK product sorting, stands for quality: Camera inspection Omron / integrated by Beck Automation CAP 2: Image/diagram bfa solutions CAP 3: High-end look at the point of sale: Labels by Viappiani CAP 4: Energy-efficient cooling concepts by ef cooling: "Free cooling" using cold outside air saves up to 60% in energy costs CAP 5: High-performance IML manufacturing cell IML Competence at K 2013 PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 5 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa Beck Automation at K 2013: Hall 10 G77 ███████ Contacts █████████████████████████████████████████████████ Beck Automation AG Neugutstrasse 19 CH - 8102 Oberengstringen Schweiz | Switzerland | Suisse Phone: +41 (0) 44 751 84 44 www.beck-automation.com Management: Nicolas Beck Media relations: Daniel Merki Phone: +41 44 751 84 66 E-mail: d.merki@beck-automation.com Glaroform AG: www.glaroform.ch PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 6 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa Ernst H. Furrer AG – ef cooling: www.efcooling.com Viappiani Printing: www.viappiani.it bfa solutions Ltd.: www.bfa.ch __________________________________________________________________________ About Beck Automation AG Beck Automation AG from Oberengstringen, Switzerland, is a world leading provider of automation solutions for IML (In-Mold Labeling) in injection molding. Beck focuses consistently on decorating and labeling lids, pots, tubs and buckets for various industries. Tailored to exacting customer specifications, process reliable and economic robot systems are built that are deployed around the globe. This consistent focus on IML guarantees that users get the finest state of the art in terms of quality, economic efficiency, effectiveness and durability. Run by the second and third generation of the family, the company establishes and maintains long-term relations to market partners with a forward-looking and sustainable policy. This strategy secures the jobs of committed and experienced staff. A traditional structure, a tried and tested network of partners, and astute adaptation to changes form the basis for ongoing company development and inspiration on behalf of partners, customers and staff. Beck Automation was established in 1934 and celebrated its 75th anniversary in 2009. Over 500 reference systems highlight the company's global significance. Approximately 35-45 system plants are shipped from the Swiss headquarters each year. Beck Automation with 37 staff achieved sales of CHF 9M in 2012. PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 7 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa About Glaroform AG Glaroform AG in Näfels, Switzerland, is a modern tool and die-making company that has been specializing in high-performance plastic injection molds since 1986. Our 40 qualified staff manufacture high-quality state-of-the-art molds. The molds are designed in-house by very experienced and well-trained specialists. Extremely precise manufacturing is done on modern machinery with tight tolerances. The latest surface coating processes guarantee the long service life for which Glaroform molds are renowned. Injection molds and the on site hot runner system are continuously being adapted and developed according to customer specifications and market requirements. In order to keep pace with rapid developments in molding, the company has largely specialized in injection molds for thin-walled articles. The range includes margarine, gourmet foods, ice cream, food and non-food containers, drinking cups, buckets, lids and plant pot. The products can be designed in different formats: round, oval, square or rectangular, with or without a temper evident closure. Today the products are primarily decorated using IML. About Ernst H. Furrer AG – ef cooling ef cooling in Dällikon, Switzerland, is an internationally leading manufacturer of process cooling systems for the industry. Besides standardized equipment for cooling water, oil emulsions and emulsions up to approx. 400kW cooling capacity, it primarily plans and produces complete cooling systems up to 5kW cooling capacity. As part of this type of turn key project, they offer the entire services from planning to delivery to assembly and commissioning. Emphasis is placed on environmentally friendly concepts with energy-saving technologies, meaning outputcontrolled components in the coolant and hydraulic systems. Ventilator and pump motors, compressors and expansion valves are adjusted electronically to the system's current operating points. At the same time, so-called "free cooling" is becoming increasingly more popular. This PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 8 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa means that cooling is achieved with cold outside air, as long as the difference is sufficient to permit the desired medium temperature.The use of compressors is unnecessary in this phase. In this way, power costs can be cut by up to 60%. ef cooling builds on high-quality engineering and system design – worldwide. Custom engineering gives customers environmentally friendly systems with a definite trend toward green technology. Since January 2013 ef cooling is represented by a subsidiary in Germany: Furrer Industriekühlung GmbH in Krukow near Hamburg. This ensures extensive sales and consulting as well as comprehensive services throughout Germany. About Viappiani Printing From its headquarters in Segrate near Milan, Italy, Viappiani Printing supplies the international market with a broad variety of labels, focusing on PP, PE, and PS film-based IML labels. Viappiani Printing is a member of CTI Invest AG, a private holding company specialized in printing, with branches in Europe (Italy, Germany and Spain), North America (Canada) and South America (Colombia, Argentina and Brazil). Innovation and investments into the latest technologies are guaranteed. CTI aspires to a global network of label suppliers, meaning that customers will be able to have local support worldwide. Established in 1929 by Bruno Viappiani, Viappiani quickly became a specialist for labels. In the 1980s Viappiani Printing was one of the first to manufacture IML labels for plastic containers on the European market. Now, 30 years later, Viappiani Printing is a leading IML label manufacturer for injection and blow molding processes with the goal of supplying the finest quality labels for machines. PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 9 of 10 ____________________________________________________ Press Release | Presseinformation | Communiqué de presse | Communicado de prensa | Comunicato stampa | Пресс-релиз | Imprensa | Persbericht | Notatka prasowa About bfa solutions ltd. bfa solutions ltd. in Schwerzenbach, Switzerland, is an engineering company that has been in existence for over 30 years and is highly competent in industrial automation and production processes. It has cross-disciplinary expertise and comprises computer engineering in addition to traditional automation engineering. This enables the design and implementation of solutions at the system control level (PLC) on the production level via data-centered capture of production data up to the interface with ERP systems and mobile applications. The PiSolutions product portfolio in MES ranges from capturing operating data of a few systems of different ages and type (different interfaces, controls, etc) to networking several locations of global companies. Services in automation system engineering are also in high demand. They are not limited to specific industries. Established solutions from bfa solutions ltd. are particularly popular in plastics processing, the packing industry and medical engineering. PR 8-2013 Document1 Words : 1.015 | Characters : 5.487 Page 10 of 10