Toxic and corrosive chemicals

advertisement

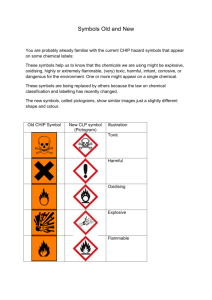

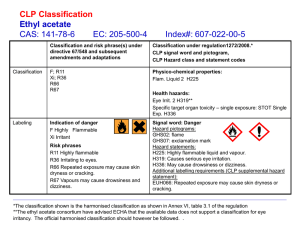

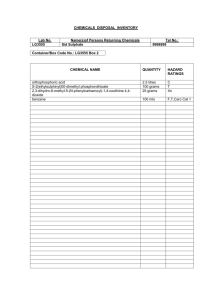

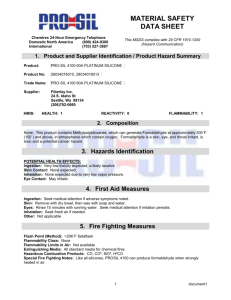

Assessment Procedure for Significant Risks This form is to be used to record significant risks not covered by any of your departmental generic risk assessments. (If all the work is covered by generic assessments there is no need to continue any further with this document.) The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) (B) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (almost never, not expected at all) (foreseeable, but only occurring rarely) (could occur, but uncommon) (recurrent but not frequent) (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Moderate Serious Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 generic-RA-toxic-corrosive-chemicals-2013-v1 Fatal LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but review periodically to ensure controls remain effective Continue, but implement additional reasonably practicable controls where possible and monitor regularly STOP THE ACTIVITY Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Page 1 Generic Risk Assessment for toxic or corrosive chemicals Drafted by Pete Jewell Location of activity: July 2013 Policy and guidance for various aspects of work with hazardous chemicals is available at the UHS&E website (http://www.bath.ac.uk/hr/stayingsafewell/index.html) and the ‘1st Stop for Health & Safety’ wiki at https://wiki.bath.ac.uk/pages/viewpage.action?pageId=73829286. This risk assessment only covers work with toxic and corrosive chemicals. Any other significant hazards involved in the work activity must also be assessed in more detail using one of the more specialised generic, or specific, risk assessments available on the wiki. Once complete, all relevant workers must be informed, and their supervisor/manager must record their agreed ‘competence’ level (e.g. using a ‘supervision level’ of ‘low’, ‘medium’ or ‘high’) and get them to sign below. Date when will the activity is to start: Date when it is likely to finish: Assessor(s) names(s): Supervisor(s): Signatures of Date: Date of drafting assessment: Safety Coordinator: Date: Roughly how often will it be performed? Review date: Head of Department; Date: Supervision level. (Complete this after assessment is printed.) Supervisors and workers must jointly agree worker’s supervision level, defined as follows; 'LOW' - Workers are deemed to be adequately 'MEDIUM' - Activity cannot commence 'HIGH' - Activity cannot commence or proceed without direct senior supervision. trained and competent to perform this activity. without supervisor’s advice and approval. Worker’s name Worker’s signature generic-RA-toxic-corrosive-chemicals-2013-v1 Supervision level Supervisor’s name Supervisor’s signature Date Page 2 For help with the management of hazardous chemicals contact the relevant specialist via UHSE@lists.bath.ac.uk. . Specific risk assessments must be made for; work with chemicals of extreme acute toxicity (eg those with o LD50 (oral) rat < 5mg/Kg, LC50 (rat) (4 hour), < 0.1mg/litre, o Workplace Exposure Limit (WEL) (equating to OES [occupational exposure standard], MEL [maximum exposure limit] or TLV [threshold limit value]) of < 10ppm or < 0.5mg/m3 (refer to relevant material safety data sheets – MSDS) o Hazard Statements (or Risk phrases) H300 (R28), H310 (R27), H314 (R35), H318 (R41), H330 (R26), H362 (R64), H370 (R39), H372 and H373 (R48)) work with substances where exposure is likely to cause carcinogenic, mutagenic or teratogenic effects in humans. Such compounds have been assigned Hazard Statements (or Risk phrases) H340 (R46, R47), H350 (R45, R49), H360 (R61), H361 (R62 and R63). work involving the large-scale manipulation or processing of more than 1 Kg or 2.5 litres of any toxic or corrosive chemical. chemical agents on the list of ‘dual-use’ materials (ask for guidance from UHS&E Service) for which labs must have an up-to-date inventory. General Risk Control Measures. Completion of departmental safety induction is mandatory for lab workers. Lab coats must be worn by all workers in “wet” laboratories. Food or drink must not be consumed or stored in “wet” labs. Good standards of personal hygiene must be maintained at all times. Hand-toface operations must be avoided. Hands must be washed when leaving lab. Mouth pipetting or the use of mouth-operated suction devices is prohibited. POWDERED LATEX GLOVES ARE PROHIBITED IN THE UNIVERSITY. Lowprotein, non-powdered latex and nitrile disposable gloves (to EN374-2 and EN3743 Standard) should be available for use in laboratories. To avoid contaminating door handles and light switches lab gloves should not be worn outside labs. If necessary use one glove to carry lab items. All laboratories must maintain an inventory of any ‘dual-use’ materials to help with audits. This inventory must be checked at least annually. Spillages should be dealt with as soon as possible. Neutralise, if appropriate, and clear up. Hazardous chemical spillages may need specialised disposal and if you are not sure how to dispose of any hazardous waste please contact your Technical Manager or email waste@lists.bath.ac.uk. It may be appropriate to dispose of some spills to the drains or to the general “red-label” waste bins. If you are not sure SEEK ADVICE. In the case of volatile liquids, use tissues and consider removing them as soon as possible (to enable the vapours to dissipate) either to a ducted fume cupboard or outside the building. First aid. For chemical spillages on body surfaces (exposed skin and eyes) the main aim must be to remove contaminating material as soon as possible. This is almost invariably achieved by flushing the affected area with cold tap water for up to 15 minutes. Each “wet” lab should have a hand-held emergency shower by each hand-wash basin adjacent to exit doors. (Additional advice on first aid treatment should be included in any specific risk assessment.) Where specific first aid treatment should be considered (e.g. when using cyanides or phenol) it must be detailed in the specific risk assessment involving those agents. For needlestick injuries, encourage the wound to bleed, rinse the wound site under cold water and follow any guidance given in specific risk assessments. Minor cuts can be treated locally. Basic first aid materials (adhesive wound dressings) should be readily available. For any injury at work, if irritation persists then you should seek medical attention. If your injury cannot be controlled then you should report to your GP, the University Medical Centre (200 metres to the west of the Building 2 South), the NHS Walk-in Centre in Bath or the Accident and Emergency unit at the Royal United Hospital in Bath. For emergency help the University internal telephone number 666 should be used. University Security staff are trained first aiders. A list of departmental or building first aiders should be displayed in departments. Incident reporting mechanisms. Injuries (even minor ones) dangerous incidents, and hazards should be reported on the A4 Incident report forms, available online at http://www.bath.ac.uk/hr/stayingsafewell/accidents-emergency/docsaccidentsandemergencies/Incident_report_form_V2.docx. generic-RA-toxic-corrosive-chemicals-2013-v1 Page 3 Changes to chemical classification and labelling are being phased in. Refer to important information from page 8 of this assessment. Be aware of the new regime when reviewing catalogues, container labels and Material Safety Data Sheets (MSDS). Particularly vulnerable groups at risk How could they be harmed? Risk before controls implemented A B Control measures needed to minimise risk A AxB By skin/eye contact, inhalation, ingestion. 5 4 20 People working for prolonged periods with chemicals having a recognised cumulative or irreversible effect By skin/eye contact, inhalation, ingestion. 5 3 15 Pregnant, or breast-feeding, women By being exposed to teratogenic and toxic chemicals. 5 3 15 Woman must inform supervisor or HR manager of her pregnancy Supervisor must perform specific risk assessment. 5 3 15 If worker is aware of a particular sensitivity they must declare this to their supervisor or HR manager. Supervisors must identify work with known sensitisers, compile a risk assessment and request HR refer workers to the OH provider. Supervisor must perform specific risk assessment. 5 3 15 Supervisor must ensure a PEEP (personal emergency evacuation plan) is provided. Volume of personal music player must not be set too loud to mask emergency alarm or verbal warnings from others in the vicinity. By exposure to some agents capable of sensitising workers or exacerbating their condition. People who might be less mobile or have a hearing or sight impediment or are listening to music with earphones (during an emergency evacuation of either building) By being isolated in a burning building and unable to escape. By not hearing warnings from other people in the vicinity. B Supervisors must ensure all lab workers are provided with – a. Pertinent information. b. Competent instruction. c. Basic safety induction training. d. Relevant training for specialised tasks. e. Appropriate supervision. f. Suitable and sufficient risk assessments. The precautions adopted must prevent significant exposures as indicated by environmental or personal monitoring. Health surveillance may be required for those (other than pregnant women) at special risk Inexperienced workers (including undergraduate students, school pupils on “work experience” schemes and visitors). Persons with a history of particular medical conditions such as allergies to latex, respiratory disorders, or those with skin conditions such as eczema Risk after controls implemented Toxic chemicals can cause ill-health (even death) following exposure by inhalation, ingestion or skin contact. generic-RA-toxic-corrosive-chemicals-2013-v1 Page 4 AxB Toxic chemicals may cause specific diseases or affect particular organs or body functions. These effects may follow from exposure to a single large dose or to small doses repeated over a prolonged time period (cumulative effects). Effects may be immediate (acute) or long term (chronic). A combination of toxic chemicals may have a greater effect than each individually (a synergistic effect). Corrosive chemicals destroy living tissue at the point of contact and so cause severe burns, perhaps with permanent scarring or tissue changes. Corrosive chemicals will also damage or affect inanimate objects by chemical action. Hazard, due to working with; gases, aerosols, volatile liquids or dusty solids which readily become airborne. (The risk from inhaling hazardous dust while weighing and dissolving it is likely to be greater than working with a concentrated solution of it.) chemicals of high lipid solubility which are readily absorbed (along with any solute) through the skin, mucous membranes or conjunctiva. highly concentrated solutions or mixtures of toxic or corrosive chemicals. highly toxic chemicals as determined by LD50 or defined occupational exposure limits (WELs, TLVs, MELs or OESs), or those where there is a danger of irreversible effects (carcinogens, mutagens or teratogens) or cumulative effects (e.g. heavy metals). Who could be harmed? How could they be harmed? Inhalation (then ingestion) Risk before controls implemented A A AxB 5 3 15 5 3 15 Workers and those in the vicinity Skin/eye contact (by splashing) 5 3 15 Skin/eye contact, inhalation, ingestion generic-RA-toxic-corrosive-chemicals-2013-v1 Control measures needed to minimise risk Risk after controls implemented A B AxB 5 3 15 All laboratories must maintain an inventory of any ‘dual-use’ materials (contact UHS&E for details). This inventory must be checked at least annually. This will be invaluable in managing their use. Identify the hazards of all chemicals and mixtures from suppliers’ data, container labels or standard reference texts. Then evaluate the risks of using them. Ensure that appropriate storage, use, disposal and emergency procedures are established before ordering any chemical. (Flushing spills from exposed skin with water is invariably the best initial first-aid procedure.) Wear protective clothing (properly fastened laboratory coat and safety spectacles). Suitable gloves (e.g. non-powdered latex for basic protection, PVC for acids and bases, nitrile for organic solvents) and/or additional eye/face protection may also be necessary. Examine all personal protective clothing and equipment before use and replace any that are damaged. Thoroughly wash your hands after working with toxic or corrosive chemicals. Page 5 any toxic or corrosive chemical in open vessels or apparatus or where dilution or extraction of the airborne chemical by ventilation (e.g. fume cupboard) is not practicable or effective in reducing exposures below a defined occupational exposure limit. any chemical or chemical mixture likely to form toxic or corrosive by-products or intermediates, or which results in the generation of toxic or corrosive waste residues. 5 3 15 5 3 15 any chemical of unknown purity or composition. Continuous, prolonged or frequent work with large quantities of chemicals where exposures may exceed 50% of any defined occupational exposure limit or where accidental exposures through spillage or contamination may have serious health consequences. Work involving the mixing or reaction of toxic or corrosive chemical reagents or the formation of toxic or corrosive intermediates or products in such a way that the reaction conditions (order and rate of mixing, reaction temperature and pressure) are not effectively controlled and monitored. 5 3 15 Workers and those in the vicinity Skin/eye contact, inhalation, ingestion generic-RA-toxic-corrosive-chemicals-2013-v1 5 3 15 5 3 15 Do not eat, drink, smoke, apply cosmetics or manipulate contact lenses in any “wet” laboratories or store-room where chemicals are kept or used. Mouth pipetting or the use of mouth-operated suction devices is prohibited. Carry out all procedures and manipulations involving hazardous gases, aerosols, volatile substances or dusts in enclosed apparatus or equipment or in an effective fume cupboard, glove box or equivalent containment device. Note that carbon-filtered recirculating cabinets may not give adequate protection from the hazardous components. Check the operation of fume cupboards, glove boxes and equivalent containment devices used to prevent or control exposures by observing any fitted anemometer. All containers must be clearly labelled to show the chemical name and hazards. For solutions and preparations made in the lab, the composition and concentration of each component as well as the name of the person who made it and the date of preparation should also be on the label. Store according to the suppliers’ instructions and ensure that incompatible chemicals are stored so that accidental mixing cannot occur. Dispose of toxic or corrosive chemical waste and residues according to suppliers’ instructions or collect in suitable labelled containers for removal and disposal as Special waste via your Departmental procedures. Advice on waste disposal can be sought from waste@lists.bath.ac.uk. 5 3 15 Page 6 Action Plan for additional control measures needed. Do any stated control measures need to be implemented before this activity can take place? Action Plan in respect of actions: Ref no. Prepared by: Action to be taken, including cost By whom Target date Responsible manager’s signature: Print name: Review date Outcome at review date Responsible manager’s signature: Date: Print name: Date: Assessment must be reviewed annually by responsible manager. generic-RA-toxic-corrosive-chemicals-2013-v1 Page 7 Changes to chemical classification and labelling Please be aware of the new regime when reviewing catalogues, container labels and Material Safety Data Sheets (MSDS). The CHIP scheme. Risk and Safety phrases (also known as R/S statements, R/S numbers, R/S phrases, and R/S sentences) and hazard warning pictograms, are part of a system for labeling dangerous chemicals and compounds in the European Union. In the UK the Chemicals (Hazard Information and Packaging for Supply) Regulations 2009 - known as CHIP 4 or CHIP, is the set of Regulations controlling this. The HSE produce a web page (refer to http://www.hse.gov.uk/chip/phrases.htm) describing the pictograms and R/S statements in use up until 2016 when they must be phased out. The CLP scheme. Both the CHIP risk and safety phrases are being phased out in favour of Hazard Statements and Precautionary Statements under the EU's implementation of the worldwide Globally Harmonized System (GHS) of Classification and Labelling of Chemicals. In adopting GHS the EU implemented European Regulation (EC) No 1272/2008 on Classification, Labelling and Packaging of Substances and Mixtures (CLP Regulation). Pictograms will also be changing. The GHS/CLP Hazard statements are intended to form a set of standardized phrases about the hazards of chemical substances and mixtures that can be translated into different languages. As such, they serve the same purpose as the well-known R-phrases, which they are intended to replace. Hazard statements are separated into H200 series (Physical hazards); H300s (Health hazards); and H400s (Environmental hazards). There is a more comprehensive coverage of hazardous properties and although many of the phrases have a similar meaning they are worded differently, for example (CHIP CLP): R28 Toxic if swallowed H300 Fatal if swallowed R 34 Causes burns H314 Skin corrosive R 45 May cause cancer H350 Carcinogen R42 May cause sensitisation by inhalation H334 May cause allergy or asthma symptoms or breathing difficulties if inhaled. Conversion tables are given on the following pages. Hazard statements are one of the key elements for the labeling of containers under the GHS, along with: an identification of the product; one or more hazard pictograms (where necessary) a signal word – either DANGER or WARNING – where necessary precautionary statements, indicating how the product should be handled to minimize risks to the user (as well as to other people and the general environment). These are similar to the safety (S) phrases under the CHIP system. the identity of the supplier (who might be a manufacturer or importer) Each hazard statement is designated a code, starting with the letter H and followed by three digits. Statements which correspond to related hazards are grouped together by code number, so the numbering is not consecutive. The code is used for reference purposes, for example to help with translations, but it is the actual phrase which should appear on labels and safety data sheets. The HSE have produced a “CLP Regulation: Implications and guidance” web page at http://www.hse.gov.uk/ghs/implications.htm#chip-hse-approved. Examples of pictogram changes (CHIP CLP) – │ generic-RA-toxic-corrosive-chemicals-2013-v1 │ Page 8 Transition period. The CLP Regulation provides a transitional period to allow a gradual migration from the existing CHIP system to the new regime. This is a summary of the obligations on chemical substance suppliers throughout the transitional period: 1st December 2010 – 1st June 2015 Suppliers must classify substances according to both CHIP and CLP. They must label and package according to CLP. 1st June 2015 onwards Suppliers must classify, label and package according to CLP. Please be aware of the new regime when reviewing catalogues, container labels and Material Safety Data Sheets (MSDS). For more information on the changes please refer also to these suppliers’ web pages - VWR, Fisher and Sigma-Aldrich. Hazard Statements (CLP) and comparable R-Phrases (CHIP) EUH0** Special EU Supplementary General Physical Hazard Statements Code Statement EUH001 EUH006 EUH014 Explosive when dry Explosive with or without contact with air Reacts violently with water In use, may form flammable/explosive vapour-air mixture EUH019 EUH029 EUH030 EUH018 Comparable R phrase Comparable R phrase Code Statement R1 R6 R14 EUH031 EUH032 EUH044 Contact with acids liberates toxic gas Contact with acids liberates very toxic gas Risk of explosion if heated under confinement R31 R32 R44 R18 EUH059 Hazardous to the ozone layer R59 May for explosive peroxides R19 EUH066 Contact with water liberates toxic gas Can become highly flammable in use R29 R30 EUH070 EUH071 Repeated exposure may cause skin dryness or cracking Toxic by eye contact Corrosive to the respiratory tract R66 R39-41 EUH2** Special EU rules for supplemental label elements for certain substances or mixtures Code EUH201 EUH202 EUH203 EUH204 EUH205 Statement Contains lead. Should not be used on surfaces liable to be chewed or sucked by children Cyanoacrylate. Danger. Bonds skin and eyes in seconds. Keep out of the reach of children Contains Chromium (VI). May produce an allergic reaction Contains isocyanates. See information supplied by the manufacturer Contains epoxy constituents. See information supplied by the manufacturer generic-RA-toxic-corrosive-chemicals-2013-v1 Comparable R phrase Code R1 EUH206 R6 EUH207 R14 EUH208 R18 EUH209 R19 EUH210 Statement Warning! Do not use together with other products. May release dangerous gases (chlorine) Warning! Contains cadmium. Dangerous fumes are formed during use. See information supplied by the manufacturer. Comply with the safety instructions Contains (name of sensitizing substance). May produce an allergic reaction Can become highly flammable in use or Can become flammable in use Safety data sheet available on request Comparable R phrase R31 R32 R44 R59 R66 Page 9 H2** Physical Hazard Statements Code H200 H201 H202 H203 H204 H 205 H220 H221 H222 H223 H224 H225 H226 H228 Statement Comparable R phrase H240 H241 H242 H250 H251 H252 Unstable explosives Explosive; mass explosion hazard Explosive, severe projection hazard Explosive; fire, blast or projection hazard Fire or projection hazard May mass explode in fire Extremely flammable gas Flammable gas Extremely flammable aerosol Flammable aerosol Extremely flammable liquid and vapour Highly flammable liquid and vapour Flammable liquid and vapour Flammable solid Code R12 H260 R10 R12 R10 R12 R11 H261 H270 H271 H272 H280 R10 H281 R10 H290 Statement Heating may cause an explosion Heating may cause fire or explosion Heating may cause a fire Catches fire spontaneously if exposed to air Self heating: may catch fire Self heating in large quantities: may catch fire In contact with water releases flammable gases which may ignite spontaneously In contact with water releases flammable gas May cause or intensify fire; oxidizer May cause fire or explosion; strong oxidizer May intensify fire; oxidizer Contains gas under pressure; may explode if heated Contains refrigerated gas; may cause cryogenic burns or injury May be corrosive to metals Comparable R phrase R5 R5, R7 R7, R12 R17 R15-17 R15 R8 R9 H3** Health Hazard Statements Code Statement Comparable R phrase Code Statement Comparable R phrase H300 Fatal if swallowed R28 H330 Fatal if inhaled R26 H301 H302 H304 Toxic if swallowed Harmful if swallowed May be fatal if swallowed and enters airways R25 R22 R65 H331 H332 Toxic if inhaled Harmful if inhaled R23 R20 H310 H311 H312 H314 Fatal in contact with skin Toxic in contact with skin Harmful in contact with skin Causes severe skin burns and eye damage R27 R24 R21 R34, R35 H334 May cause allergy or asthma symptoms or breathing difficulties if inhaled R42 H335 H336 May cause respiratory irritation May cause drowsiness or dizziness R37 R67 H315 H317 Causes skin irritation May cause an allergic skin reaction R38 R43 H340 May cause genetic defects (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) R46 H318 H319 Causes serious eye damage Causes serious eye irritation R41 R36 H341 Suspected of causing genetic effects (state route of exposure if it is conclusively proven that no other routes of exposure can cause the hazard) R68 generic-RA-toxic-corrosive-chemicals-2013-v1 Page 10 H350 H350i H351 H360 H361 H362 May cause cancer (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) R45 May cause cancer by inhalation R49 Suspected of causing cancer (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) May damage fertility (H360F) or the unborn child (H360D) (state specific effect if known) (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) Suspected of damaging fertility (H361f) or the unborn child (361f) (state specific effect if known) (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) May cause harm to breast fed children H4** Environmental Hazard Statements H400 Very toxic to aquatic life To avoid risks to human health and the environment, H401 comply with the instructions for use H410 Very toxic to aquatic life with long lasting effects H411 Toxic to aquatic life with long lasting effects H412 Harmful to aquatic life with long lasting effects H413 May cause long lasting harmful effects to aquatic life generic-RA-toxic-corrosive-chemicals-2013-v1 H370 R40 H371 R60 (H360F), R61 (H360D) H372 R62 (H361f), R63 (H361d) R64 H373 Causes damage to organs (or state all organs affected, if known) (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) May cause damage to organs (or state all organs affected, if known) (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) Cases damage to organs (or state all organs affected, if known) through prolonged or repeated exposure (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) May cause damage to organs (or state all organs affected, if known) through prolonged or repeated exposure (state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard) R39/23, R39/24, R39/25, R39/26, R39/27, R39/28 R68/20, R68/21, R68/22 R48/23, R48/24, R48/25 R48/20, R48/21R48/22 R50 R53 R51-53 R52-53 R53 Page 11 Safety Phrases (CHIP) S1 Keep locked up S2 Keep out of reach of children S3 Keep in a cool place S4 Keep away from living quarters S5 Keep contents under….. (appropriate liquid to be specified by manufacturer) S6 Keep under….. (inert gas to be specified by manufacturer) S7 Keep container tightly closed S8 Keep container dry S9 Keep container in a well ventilated place S12 Do not keep container sealed S13 Keep away from food, drink and animal feedstuffs S14 Keep away from ….. (incompatible materials to be indicated by the manufacturer) S14a Keep away from acids, alkalis, heavy metal salts and reducing substances S14b Keep away from reducing substances (e.g. amines), acids, alkalis and heavy metal compounds (e.g. activators, drying agents, metallic soaps) S15 Keep away from heat S16 Keep away from sources of ignition – no smoking S17 Keep away from combustible material S18 Handle and open container with care S20 When using do not eat or drink S21 When using do not smoke S22 Do not breathe dust S23 Do not breathe gas/fumes/vapour/spray (appropriate wording to be specified by the manufacturer) S23a Do not breathe vapour/aerosol S23b Do not breathe gas/vapour S23c Do not breathe gas/vapour/aerosol S23d Do not breathe vapour S23e Do not breathe aerosol S23f Do not breathe gas S23g Do not breathe smoke S24 Avoid contact with skin generic-RA-toxic-corrosive-chemicals-2013-v1 S25 S26 S27 S28 S28a S28b S28c S28d S28e S28f S28g S28h S28i S28j S29 S30 S33 S35 S36 S37 S38 S39 S40 Avoid contact with eyes In case of contact with eyes, rinse immediately with plenty of water and seek medical advice Take off all contaminated clothing immediately After contact with skin, wash immediately with plenty of….. (to be specified by the manufacturer) After contact with skin, wash immediately with plenty of water After contact with skin, wash immediately with plenty of water and soap After contact with skin, wash immediately with acetic acid 3% and plenty of water After contact with skin, wash immediately with polyethylene glycol, followed by plenty of water After contact with skin, wash immediately with polyethylene glycol, followed by plenty of water After contact with skin, wash immediately with plenty of a 1:1 solution of polyethylene glycol:ethanol After contact with skin, wash immediately with plenty of cuprous sulphate solution, 2% After contact with skin, wash immediately with plenty of lutrol After contact with skin, wash immediately with plenty of propylene glycol After contact with skin, wash immediately with plenty of propylene glycol 400 (Roticlean) Do not empty into drains Never add water to this product Take precautionary measures against static discharges This material and its container must be disposed of in a safe way Wear suitable protective clothing Wear suitable gloves In case of insufficient ventilation wear suitable respiratory equipment Wear eye/face protection To clean the floor and all objects contaminated by this material, use….. (to be specified by the S40a S40b S40c S41 S42 S42a S42b S43 S43a S43b S45 S46 S47 S48 S48a S49 S50 S50a S50b S50c S50d manufacturer) To clean the floor and all objects contaminated by this material, use plenty of water To clean the floor and all objects contaminated by this material, use diluted alkaline solution To clean the floor and all objects contaminated by this material, use iodized active carbon In case of fire or explosion do not breathe fumes During fumigation/spraying wear suitable respiratory protective equipment (appropriate wording to be specified by the manufacturer). During fumigation wear suitable respiratory equipment During spraying use suitable respiratory equipment In case of fire, use….. (in the space indicate the precise type of fire fighting equipment. If water increases the risk, add ‘Never use water’) For extinguishing, use sand, earth, powder or foam Never use water In case of accident or if you feel unwell, seek medical advice immediately (show the label where possible) If swallowed, seek medical advice immediately and show this container or label Keep at a temperature not exceeding…oC (to be specified by the manufacturer) Keep wet with….. (appropriate material to be specified by manufacturer) Keep wet with water Keep only in the original container Do not mix with….. (to be specified by manufacturer) Do not mix with peroxide activators and reducing agents Do not mix with acids Do not mix with alkali Do not mix with other chemicals Page 12 S51 S52 S53 S56 S57 Use in only well ventilated areas Not recommended for interior use on large surface areas Avoid exposure – obtain special instructions before use Dispose of this material and its container to hazardous or special waste collection point Use appropriate container to avoid environmental contamination S59 S60 S61 S62 Refer to manufacturer/supplier for information on recovery/recycling This material and its container must be disposed of as hazardous waste Avoid release to the environment. Refer to special instructions/safety data sheets If swallowed, do not induce vomiting; seek medical advice immediately and show this container or label S63 S64 In case of accident by inhalation; remove casualty to fresh air and keep at rest If swallowed, and person is conscious, rinse mouth with water Precautionary Statements (CLP) and comparable S-Phrases (CHIP) Code Statement P1** General Precautionary Statements If medical advice is needed, have product container or label P101 at hand P102 Keep out of reach of children P103 Read label before use P2** Prevention Precautionary Statements P201 Obtain special instructions before use Do not handle until all safety precautions have been read P202 and understood Keep away from heat / sparks / open flames / hot surfaces P210 No Smoking P211 Do not spray on an open flame or other ignition source P220 Keep / Store away from clothing/…/combustible materials P221 Take any precaution to avoid mixing with combustibles/.. P222 Do not allow contact with air. Keep away from possible contact with water, because of P223 violent reaction and possible flash fire P230 Keep wetted with… P231 Handle under inert gas P232 Protect from moisture P233 Keep container tightly closed P234 Keep only in original container P235 Keep cool P240 Ground / bond container and receiving equipment Use explosion-proof electrical / ventilating / lighting P241 equipment P242 Use only non-sparking tools P243 Take precautionary measures against static discharge generic-RA-toxic-corrosive-chemicals-2013-v1 Comparable S Phrase S45 P244 P250 P251 P260 P261 P262 P263 P264 P270 P271 P272 P273 P280 P281 P282 P283 P284 P285 S5 S6 S8 S7 S3 Keep reduction valves free from grease or oil Do not subject to grinding / shock / friction Pressurized container: Do nor pierce or burn, even after use Do not breathe dust / fume / gas / mist / vapour / spray Avoid breathing dust / fume / gas / mist / vapour / spray Do not get in eyes, on skin, or on clothing Avoid contact during pregnancy / while nursing Wash thoroughly after handling Do not eat, drink or smoke when using this product Use only outdoors or in a well-ventilated area Contaminated work clothing should not be allowed out of the work-place Avoid release to the environment Wear protective gloves / protective clothing / eye protection / face protection Use personal protective equipment as required Wear cold insulating gloves / face shield / eye protection Wear fire / flame resistant / retardant clothing Wear respiratory protection In case of inadequate ventilation wear respiratory protection S23 S24 S25 S28 S20-21 S36 S38 P3** Response Precautionary Statements P301 If swallowed: P302 If on skin: P303 If on skin (or hair) P304 If inhaled: P305 If in eyes: P306 If on clothing: P307 If exposed: P308 If exposed or concerned: S33 Page 13 P309 P310 P311 P312 P313 P314 P315 P320 P321 P322 P330 P331 P332 P333 P334 P335 P336 P337 P338 P340 P341 P342 P350 P351 P352 P353 P360 P361 P362 P363 P370 If exposed or if you feel unwell: Immediately call a POISON CENTRE or doctor / physician Call a POISON CENTRE or doctor / physician Call a POISON CENTRE or doctor / physician if you feel unwell Get medical advice / attention Get medical advice / attention if you feel unwell Get immediate medical advice / attention Specific treatment is urgent (see … on this label) Specific treatment (see … on this label) Specific measures (see … on this label) Rinse mouth Do not induce vomiting If skin irritation occurs: If skin irritation or rash occurs: Immerse in cool water / wrap in wet bandages Brush off loose particles from skin Thaw frosted parts with lukewarm water. Do not rub affected area. If eye irritation persists: Remove contact lenses, if present and easy to do so. Continue rinsing Remove to fresh air and keep at rest in a position comfortable for breathing If breathing is difficult, remove to fresh air and keep at rest in a position comfortable for breathing If experiencing respiratory symptoms: Gently wash with plenty of soap and water Rinse cautiously with water for several minutes Wash with plenty of soap and water Rinse skin with water / shower Rinse immediately contaminated clothing and skin with plenty of water before removing clothes Remove / take off immediately all contaminated clothing Take off all contaminated clothing and wash before reuse Wash contaminated clothing before reuse In case of fire: generic-RA-toxic-corrosive-chemicals-2013-v1 P371 P372 P373 P374 S45 P375 P376 P377 S64 S63 S28 S27 P378 P380 P381 P390 P391 In case of major fire and large quantities: Explosion risk in case of fire DO NOT fight fire when fire reached explosives Fight fire with normal precautions from a reasonable distance Fight fire remotely due to the risk of explosion Stop leak if safe to do so Leaking gas fire: do not extinguish, unless leak can be stopped safely Use … for extinction Evacuate area Eliminate all ignition sources if safe to do so Absorb spillage to prevent material damage Collect spillage P4-- Storage Precautionary Statements P401 Store … P402 Store in a dry place P403 Store in a well ventilated place P404 Store in a closed container P405 Store locked up Store in corrosive resistant / … container with a resistant P406 inner liner P407 Maintain air gap between stacks / pallets P410 Protect from sunlight P411 Store at a temperature not exceeding … oC/ ..oF P412 Do not expose to temperatures exceeding 50 oC / 122 oF Store bulk masses greater than …kg/ …lbs at temperatures P413 not exceeding ..oC / oF P420 Store away from other materials P422 Store contents under … S8 S9 S7 S1 P5-- Disposal Precautionary Statements P501 Dispose of contents / container to … Page 14