Environmental Compliance Checklist

advertisement

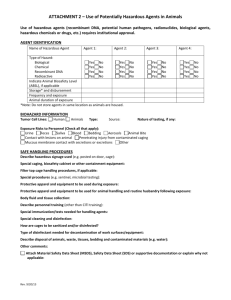

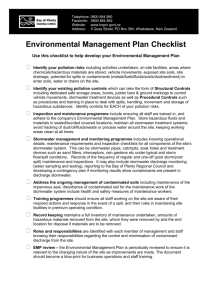

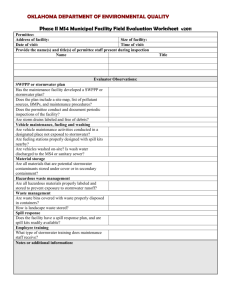

ENVIRONMENTAL COMPLIANCE CHECKLIST TRADING NAME: FILE NO.: PREMISES ADDRESS: PRIMARY ACTIVITY: PERSON INTERVIEWED: OFFICER: 1 POSITION/TITLE: DATE: RISK ASSESSMENT Are there any hazardous substances onsite? < 50 litres > 50 litres > 500 litres TIME: 17 Employees are aware of what to do in the event of both small and large spills 18 Batteries and liquids are stored in a bunded area, undercover and on an impervious surface. Mobile operators have secondary bunding containment inside the vehicle. WASTE MANAGEMENT Approved EPA licensed waste contractor details provided and records available for disposal □ Waste oil (liquid waste) □ Other liquid waste ie: oil water separator □ Used tyres (special waste) □ Batteries (hazardous waste) □ Used filters and rags (general waste) Wastes are stored in sealed containers which are undercover and in a correctly bunded area. 19 2 SITE LAYOUT Indoor work areas are covered and sealed. 3 Outdoor storage areas are covered and sealed. 4 Liquid chemicals are stored away from trafficable area and stormwater drains. 20 21 5 6 7 8 9 10 11 12 13 14 15 16 WATER QUALITY External stormwater drains are clean, clear rubbish and waste material All waste water is either collected for disposal or passed through an oil water separator Bunding is in good repair and adequate size around interceptor Interceptor/pit is cleaned out annually (minimum) Sydney Water trade waste permit sighted Wash bay/retention pit is undercover Panel preparation area Dry sanders are fitted with dust extraction or Wet sanding sludge drains to oil water separator CHEMICAL STORAGE Are the Safety Data Sheets up to date and in an easily accessible location? Bulk storage tanks stored indoors are fitted with double taps or non-spill/no drip nozzles Chemical stores that emit volatile gases are adequately ventilated Chemical storage areas are secured against unauthorised entry Spill kits containment adequate for amount of material on-site Compliance Checklist 1.2 Compliant Non-compliant INSPECTION RESULT Non-compliances 22 – Not applicable BEYOND BASIC COMPLIANCE Clear, measurable targets have been set to improve environmental performance. 23 Targets have been reviewed and re-set to further improve environmental performance. 24 Targets have been exceeded and all practical opportunities to improve environmental performance have been exhausted. Date: Owner/employee signature: Officer’s signature: Guide to Interpreting: What is Compliant 1. Hazardous Substances includes: automotive oils, paints, 13. (cont.) You must consider all liquid handling such as adhesives and solvents, waste water from car detailing, bulk delivery loading and movement of liquids on pallets. fuels and diesel, kitchen fats and oils, concrete run off, any All tanks should be fitted with a dual taps and drip trade waste, pesticides and fertilisers, cleaners and collectors detergents, food products. 14. Paint storerooms need to be adequately ventilated to Quantities refer to holding capacity ie: a 44 gallon drum has prevent a build-up of volatile organic compounds (VOC) the capacity to hold 200 litres. within an enclosed space by either natural or mechanical 2. Rainwater can carry away residual pollutants that have means. Underground storage tanks must be fitted with spilled on outdoor hardstand or unsealed areas. All work vapour recovery systems where necessary. with hazardous substances must be carried out in an 15. Hazardous goods must be stored in a lockable area undercover area where any unexpected spills can be accessible only by those trained in the correct handling contained. The containment area can be either a bunded procedures. area OR an area that is either graded to an isolated pit or 16. The premises must have adequate equipment in place drained to a sealed wall-floor section within the building. to prevent any spills or leaks from entering the stormwater A bund is a raised, impermeable barrier that forms a system or otherwise escaping to the environment. Spill kit containment area eg: a wall, speed hump, gutter, flexible contents must meet both normal operation and unexpected rubber barrier. It is acceptable to store a container within situation such as major leaks, spills and fire. Kit must be a larger container. The volume of the containment area is compatible with substances on-site; ie: water or oil based either: 100% volume of the largest container or 25% of the liquids, oxidisers, acids or alkalis. total volume of all products stored within the area. 17. Spills should be preventing from leaving the site and 3. Bunded outdoor storage areas should be covered to cleaned up immediately. All employees need to know what prevent rainwater from filling up the containment volume. to do in the event of an environmental incident and which All outdoor containment area should include an extra 10% authorities need to be notified. allowance for rainwater. Outdoor pits must not overflow to 18. Anything that has the potential to leak must be stored stormwater. on a sealed surface and covered to exclude rainwater. If it is 4. Bulk liquid storage areas must be separated from vehicle not possible to store goods inside, contaminated rainwater thoroughfares. must be collected by a licenced waste transporter. 5. Stormwater drains should be inspected and cleared as 19. Containment measures are the same whether liquid required to prevent leaf litter, sediment, or any other substances are being used or stored at a single location or pollutants entering the system. Some sites may be fitted as part of a mobile service. with first flush devices that contain and direct surface run20. Records must be maintained to prove that the waste off to sewer. has been disposed of properly. Some solid wastes may need 6. Any dirty wash water must not go to storm-water, it to be disposed of by a waste collection service that is must be directed to sewer. The waste may require prelicensed to collect wastes that are classified as hazardous or treatment before it can be accepted to the sewer. industrial. Operator must be able to show collection 7. The oil water separator itself is a source of pollution, it dockets which include contactors Environment Protection must be bunded to prevent run-off during overflow or Licence (EPL) number. failure. The size of the bund must match the holding 21. Empty containers should be washed, rinsed or sealed capacity of the separator. before disposal or storage. Empty containers used to hold 8. There are no strict guidelines outlining when the device hazardous goods still contain small amount of products and must be cleaned out. At a minimum, inspection and clean must be disposed of through a licensed waste facility. out is required once a year. Premises must be able to 22. Businesses are encouraged to further reduce their produce receipts to prove who transported away separator environmental impact by setting goals to correct and waste and when. improve their performance. Targets must relevant and 9. Proof by way of current Sydney Water bill must be meaningful to the operation. Examples include reducing produced. This is a separate change usually highlighted in hazardous materials inventory, improving site layout, red text. reducing waste, energy and water consumption. 10. Wash bays or detailing bays must be located to prevent 23. Environmental performance has been re-assessed. rainwater filling up containment pits. Targets from the previous environmental reviews have 11. Premises set up to sand and spray vehicles must been met. New targets have been set to further reduce prevent dust from entering stormwater by either collecting environmental impacts. the sandings either wet or dry. 24. All environmental impacts have been assessed. The 12. Must be current: Safety Data Sheets are reviewed every business has integrated best practice initiatives throughout 5 years. Dangerous goods kept in manifest quantities must the operation. The organisation is an industry leader in their be kept in a cabinet at the entrance/exit of the premises. field, actively promoting and engaging external 13. Bulk tanks should be designed so that any rupture, stakeholders to help drive sustainability within the sector overflow or break can be contained. Secondary and/or community. containment areas must be sized for either: 100% volume of the largest container or 25% of the total volume of all products stored within the facility. Information derived from: Department Environment and Climate Change NSW (2007) Storing and handling liquids: environmental protection. Department of Environment and Climate Change NSW (2009) Waste Classification Guidelines NSW Workcover (2005) Storage and Handling of Dangerous Goods: Code of Practice