Soils Report - WordPress.com

advertisement

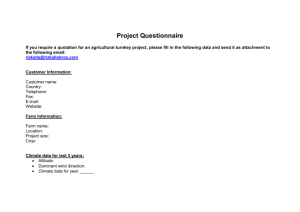

Soil Mechanics Report November 2013 Preston Merrell Abstract Soil Mechanics is a very important part of the engineering world. How soil experiments mentioned in this report help accomplish this goal. Objective reacts under loads, with various water contents, and movement will be critical in how a project should be planned. Students are to use a sieve analysis to help classify two types of soil: a sample from the Teton Dam, and a road base sample. They also measure the ultra-fine particles that cannot be measure in the sieve analysis through a hydrometer test. These values are tabulated and graphed together to show the grain diameter vs. the percent passing. The Plastic Limit, Liquid Limit, and Plastic Index are also found through two types of The objective of these experiments is to acquire data that will allow us to classify the two types of soil being used, as well as the moisture content which will allow us to note the best moisture content to allow the best compaction. Actual compaction tests will not be included in this lab. However, the students will calculate the water content of the soil in its natural state which would be used to know how much water is allowable for safety. A sieve analysis will also be used in this lab to help classify the soil. From the analysis we will tabulate the experiments. percent passing of soil in each sieve. These Introduction The study of soil behavior is a critical values will be used to classify the soil and give it a “name”. The Unified Soil part of construction for any type of project. Classification System is used most widely in Geotechnical engineers are needed in the geotechnical world for classification of almost every project to ensure the safety soils, which is what will be used in this and integrity of a structure by sampling the experiment. Any soil passing the #200 sieve, soil it will rest on to be able to make correct or the .075mm sieve, is then analyzed engineering decisions. Attention to the further by a hydrometer test. The grain minutest details of how the soil being dealt diameter can be calculated from the with reacts to moisture, weight, and distance and time of fall of the particles. movement, will save thousands of dollars and even lives. Various methods used in the The last experiments that will be basis for this test is Stokes’ law for falling included in this report will be the Liquid spheres in a viscous fluid. This law relates Limit and the Plastic Limit tests, which then the terminal velocity of the grains in allows us to calculate the Plastic Index. suspension, their density, and the density of These values, part of the family Atterberg the fluid. The diameter can be found with limits, will be very important to know from this equation: an engineering standpoint because they 𝐷(𝑚𝑚) = 𝐾√ correlate with the engineering properties 𝐿 𝑇 and engineering behavior of fine-grained D = Diameter of soil particles in suspension soils. K = Constant which is a function of specific gravity and temperature Theory The range of particle size distributions in soils is enormous. Soils can L = Effective Depth (found in attached table) T= Time of reading (minutes) You can now compare these grain range from boulders or cobbles several sizes of the particles with the percent of the centimeters in diameter down to ultrafine- soil still remaining in suspension for each grained colloidal materials. Grain sizes reading. The percent finer in suspension is between 5 mm and 0.074 mm are classified calculated by the equation according to U.S. Standard sieve number, which can be directly related to a specific 𝑃= 𝑅ℎ 𝛼 𝑊 × 100 diameter of a soil grain. Since soil particles P = Percent of soil in suspension for a given hydrometer reading are rarely perfect spheres, when we speak Rh = Hydrometer reading + Cm of particle diameters, we really mean an α = Correction factor equivalent particle diameter as determined by the sieve analysis. The sieve analysis is impractical for sieve openings less than about 0.05 to 0.075 mm. Thus for the fine-grained soils the hydrometer analysis can be used. The These found particle sizes can now be treated as if we used a tiny sieve to analyze them. They can now be imposed on a grain-size distribution graph along with the larger sieved particles. The presence of water in the voids increases, the state of the soil changes from of a fine-grained soil, as shown in figure 1, a brittle solid to a plastic solid and then to a can remarkably affect its engineering viscous liquid. Thus we can see how critical behavior. It is not only important to know it is to know these parameters when the water content of the soil, but we need construction projects are underway. to be able to compare or scale this water Methods content against some standard of engineering behavior. In these three experiments there will be two types of soil being tested; one fine-grained and the other a coarse-grained. The fine-grained soil is a sample from the actual Teton Dam site. The course-grained material is a type of road base given to the students to test. Fig. 1-Water Content representation Plasticity is one the most obvious The sieve analysis is performed by obtaining 9 different sieves, cleaning them characteristics of clayey soils. This is what to make sure no extraneous particles are distinguishes between clays and silts, and accounted for, and weighing and recording plasticity is directly related to the water each one. The sieve classification and content. diameters are ¾”, ¼”, #4 (4.75 mm), #10 (2 Albert Atterberg developed the mm), #20 (850 µm), #40 (425 µm), #60 (250 Atterberg limits, 7 limits that describe a µm), #120 (125 µm), #200 (75 µm), and Pan. fine-grained soil, and included in this family Then 1280.9g of the fine-grained material is of soil characteristics are the Plastic Limit, obtained and slowly poured into the Liquid Limit, and the Plasticity Index. These stacked sieves. A cap is placed on the top parameters are required to define the and the entire collection of sieves is set into plasticity of clays. The Plasticity Index a sieve shaker which then mechanically represents the range of water content distributes the soil particles according to where the soil is plastic. As water content their grain diameter. Each sieve is then weighed and the mass of soil retained on off the hydrometer, you can then calculate each sieve is then calculated. These values the percent finer is suspension. are important because the Percent Passing can now be calculated, which we need in order to classify the soil. The same process is then completed with the coarse-grained material, but with 1961.5g of this type. The soil passing the #200 sieve is the The liquid and plastic limits are calculated in a more eccentric way that will require a little more detail. A device developed by Casagrande called the LiquidLimit device as shown in Figure 2, and it allows one to calculate the LL. ultra-fine soil that will be used for the hydrometer to test particle size distribution. Two groups performed these experiments, however, one group failed to complete the experiment of the course-grained material for the hydrometer test. The 152H hydrometer was first calibrated by filling it with a dispersing agent and distilled water Fig. 2 – Casagrande’s LL device up to the 1000mL mark and recording the hydrometer’s value at equilibrium which became the correction factor. 50g of soil passing the #200 sieve was added to the glass cylinder with the hydrometer and distilled water, filling it up to the 1000 mL mark. Readings from the hydrometer were immediately taken starting at 4 seconds. 11 other readings ranging between this and 1450 min were taken. It is important to do this over a relatively large period of time to get a good idea of what is happening to the particles as time goes on. From the readings He defined the LL as that water content at which a standard groove cut in the remolded soil sample by a grooving tool will close over a distance of 13 mm (1/2 in.) at 25 blows of the LL cup falling 10 mm on a hard rubber plastic base. In practice, it is difficult to mix the soil so that the groove closure occurs at exactly 25 blows, so we generally mix and test the soil at 5 to 6 different water contents, each resulting in the ½-in. groove closing at blow counts higher and lower than 25. If you plot the water content versus the logarithm of the weighing them the next day to take the number of blows, you get a slightly curved difference. relationship called the flow curve. Where the flow curve crosses 25 blows, that water content is defined as the liquid limit. The Plastic Limit is a bit more arbitrary, and it requires more practice to get consistent and reproducible results. The PL is defined as the water content at which a thread of soil just crumbles when it is carefully rolled out to a diameter of 3 mm. It should break up into segments about 3 to 10 mm long. If the thread can be rolled to a smaller diameter, then the thread is too wet. If it crumbles before you reach 3 mm diameter, then the soil is too dry and you are below the PL. Properly rolled out PL thread should look like Figure 3. Fig. 3 Plastic Limit test After correctly performing these two experiments, the water contents are found by weighing the wet samples and putting them in an oven overnight to dry and then Results Using the Unified Soil Classification Standard chart in the textbook, a flow type method is used that leads to a specific conclusion on the type of soil. The flow on the chart for the Teton fine-grained soil is as follows: Course Grained->Sands->Clayey Sand. 𝐶𝑢 was calculated to be 4.38. For the coarse-grained soil, the flow is Coarse Grained->Gravel->Clean Gravel->Poorly Graded Gravel with Sand. 𝐶𝑢 for this soil was calculated to be 105.56. Table 1 represents the tabulated values of grain size and percent passing. Grain Size (mm) % Passing 19.050 100.000 6.350 98.800 4.750 98.100 2.000 93.700 0.850 80.800 0.425 64.600 0.250 53.800 0.125 30.900 0.075 8.300 0.075 3.104 0.072 1.103 0.052 0.379 0.039 0.118 0.033 0.033 0.029 0.009 0.020 0.002 0.012 2.036E-04 0.009 2.371E-05 0.006 2.617E-06 0.003 2.406E-07 0.001 1.972E-08 Table 1 – Tabulated Grain Size & % passing Figure 4 represents the fine-grained soil used in the sieve analysis. The specific results for the sieve analysis and the gravity of this soil is 2.698. When touching hydrometer test for percent passing vs. the soil, it feels very powdery and fine. grain diameter. An attempt was made to perform the PL and LL tests on the road base, but it is too course to perform these experiments with it. The instructor gave the students a different type of finer soil for experimental purposes. The Liquid and Plastic Limit tests were performed and then the water Figure 4 - Percent Passing vs. Grain Diameter for fine grained soil content was found. For the LL of the Teton Dam soil the graph is shown in figure 6. Figure 5 represents the course-grained (road base) soil data for percent passing vs. grain diameter. Figure 6 – Graph of LL test for Teton Soil Drawing a line up from 25 blows, then horizontally to the water content, we find the LL to be about 24.75%. For the finer soil Figure 5 – Percent Passing vs. Grain Diameter for course grained soil For the hydrometer analysis, the largest grain size used is just smaller than 75 µm since this was the smallest diameter given to the students, the graph is shown in Figure 7. Drawing the two lines, the LL comes out to be about 83%. types were used; one fine grained soil from the Teton Dam, and another road base material. The sieve analysis helped classify orur Teton Dam and road base soils which were Clayey Sand and Poorly Graded Gravel Figure 7 – Graph of LL test for fine clay There was an error in calculating the PL for the finer soil given to us by the instructor because of the initial weight of the sample, or it was recorded wrong, so the Teton Dam soil was the only one with a PL value calculated. After rolling out this soil with the correct amount of water, the water content came out to be 24.2%. The with Sand. The Hydrometer analysis takes what is not measurable through the sieve analysis and measures the ultra-fine particles in suspension, from which we can find the diameters. The values were tabulated and graphed with the values from the sieve analysis. The PL and LL tests allow us to know Plastic Index can now be calculated using the water content range in which the soil the equation PI=LL-PL. This value came out remains plastic. This range is called the to 0.5 for the fine, Teton Dam soil. The PI Plastic Index. It is important to know these for the other soil could not be calculated values because soil becomes useless when because PL was not available. The natural it is out of the plastic range. Studying Soil water content was calculated in the very Mechanics is extremely useful in beginning and these values are 1.61% for engineering because the integrity of any the fine, Teton Dam soil, and 2.45% for the structure depends on it. road base soil. The percent of the sample retained on the #40 sieve was 35.4%. Conclusion The purpose of these experiments are to help one understand the physical properties and mechanics of a soil. Two soil