Week 11 Lab Handout--Separations

advertisement

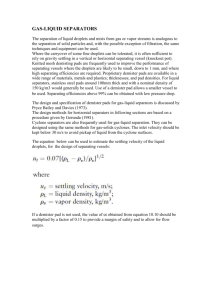

PETE 325 PETROLEUM PRODUCTION SYSTEMS LAB Lab Week 11: Three-Phase Separator Performance Lab Safety: The separator work stations each have two centrifugal pumps driven by 110 volt electric motors as well as a 110 volt air compressor. Since we will be priming the pumps and pumping hydraulic oil, water and air through the system (from storage tanks under the workbench, through the pumps and lines and back to the storage tanks) there is risk of parts of the equipment getting wet. Do not touch any part of the equipment that is wet. We will disconnect from power and dry the equipment before proceeding. Again because of possible oil or water spillage, the floor could become slippery. Please be aware and let the TA know if the floor becomes wet. The hydraulic oil used in this equipment is of very low toxicity (see MSDS), but even so, if you suspect contact with the oil, be sure to wash affected areas with soap and water immediately after contact. Parts of the experiments will call for changing flow rates and ratios of oil, water and/or air. Please do not let the pump(s) run with either the suction side or discharge side valve completely closed. Fluid passing through the pumps helps to cool and lubricate them; operation without flow can damage the pumps. Be careful to control throughput to avoid carrying oil over with the water phase and vice versa. Read and understand the operator instructions for this experiment. Objectives: Learn basic principles of operation of a three-phase separator Determine effects of varying operating conditions on separation process Determine expected vs. actual performance of the laboratory separator, including importance of o Separator volume o Fluid properties o Fluid rates o Residence time Learn how to operate and control the laboratory separator o start up, o operate under different flow conditions, o avoid process upset (carryover of fluid to wrong compartment in the separator) o shut down Resources and Equipment: eCampus Week 11 Lab Folder—Horizontal Three-Phase Separator Performance. o DarbyTech – Separator Video (two formats of same video) Be sure to watch this o Darby Three-Phase Separator—Student Exercise Manual o PGFP ch 4 and Oilfield-Oil-Water-Solids Separation Equipment and Theory Horizontal three-phase separator bench Procedure: 1. Before lab watch the demonstration video on eCampus. 2. Follow the procedures described in the DarbyTech Three-Phase Separator—Student Exercise Manual to start up, operate and shut down the separator. Be familiar with this before lab. This is critical for appropriate operation of the equipment. 3. Operate the separator under a variety of flow conditions. Note changes in separator functioning as oil rate is increased and as water rate is increased. 4. Attempt to set up conditions where an emulsion layer forms and note qualitatively differences in required residence time when emulsion is present vs. when no emulsion is formed. (Variations in air flow rate may be helpful here to set up emulsion with low enough liquid flow rates to allow enough residence time for separation to occur.) (NOTE: In Spring 2014 (1) we have had problems with too much emulsion formation. Unless we have a different oil that is not prone to emulsification, this step should be omitted. (2) Oil and water outlet sonic flow meters. Lines need to be full for meters to work. Thus only partially open the drain valves downstream of the meters. You may have to tinker a bit to get drainage rates right. 1. 2. 3. 4. 5. 6. 7. 8. Required for Report Calculate a mass balance for the separator in lab and discuss any discrepancies. Describe the function of each component of the horizontal three-phase separator (diverter, mist extractor and the two weirs and their relationship to each other. Describe effectiveness of separation and qualitatively the conditions that cause water carryover in the oil and oil carryover in the water (including effects of emulsion). Describe operating conditions where emulsion formation is likely to occur. Discuss factors that affect separation quality. Discuss the difference between onshore and offshore separation and the challenges encountered in both environments. List advantages and disadvantages of horizontal and vertical separators. Given the following flow rates and three-phase separator specifications, ignoring the volume at the two elliptical heads, calculate: a. Volume of the separator (in bbl) b. Produced water rate (bbl/day) c. Liquid residence time in the separator (in minutes) Courtesy of DarbyTech Crude oil (total fluid) mass stream entering separator = 808,593 lb/hr of gas, oil, and water Oil sold = 58,634 bbl/day Gas sold (mass stream) = 144,735 lb/hr Oil Gravity = 57 °API Separator diameter = 11 ft Separator length = 24 ft tangent to tangent Normal operating conditions = half full