transport refrigeration system

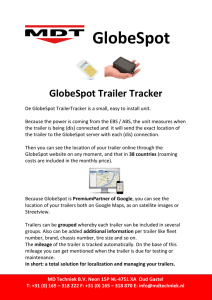

advertisement

New Project 2015 General problem description The problem we will work on will be an assessment of the relative values of both existing transport refrigeration systems and a new system. The systems to be assessed are: 1. Standard mechanical systems (Diesel/HCFC)-Thermo-king and Carrier systems for Tractor trailer and trucks 2. Liquid Nitrogen Systems (LIN)-Direct and indirect systems 3. Liquid Natural Gas Systems for Tractor trailer and trucks operating in conjuction with each of the above The values to be assessed are: Economic Efficiency Carbon reduction Use system referred to in (1) above as the basis for comparison. Operating conditions In all cases LNG is used to operate the vehicle. Refrigerated produce (fruit) maintained at 380F. Ambient temperature 800F Vehicle walls and floor preconditioned to 380F at start up Produce at 380F at start up Cargo stored on standard wooden pallets 3 ½ x 4 (each pallet is stacked with 3’ of cargo and stacked 2 high) Truck size 18lx82 Trailer size 48lx82 Three trip conditions o Trip one - 400 miles with one stop for refueling (engine off and door closed) for tractortrailer. All cargo unloaded at final stop. o Trip two -80 miles with 4 stops 45 minutes (engine off and rear door open) for tractortrailer. 25% of cargo unloaded at each stop. o Trip three - 80 miles with 4 stops 45 minutes (engine off and rear door open) for truck. 25% of cargo unloaded at each stop. Functional description of each system Mechanical system Select a system as described by one of the above manufacturers; one for a tractor trailer and one for a truck. The mechanical system will operate in following manner: Mechanical system alone - System operates continually Mechanical system with LNG system – operating with engine on. LIN systems Consider an indirect system – LIN in liquid state passing over cold plate. Fans circulating air across plate and then throughout the cargo volume Consider a direct system – LIN in liquid state injected directly into the cargo area. Each system will operate continually when required LIN system in line with LNG system. LNG system will be prime. LIN will operate only when engine off or when LNG system cannot cool adequately. LNG system LNG is prime with engine on in all cases when configured for cooling. Attachment 1 Attached is description of the LNG cooled tractor trailer system. A key feature is the two heat exchanger cooling system. Liquid natural gas (LNG) to Glycol (salt solution) heat exchanger. Glycol freezes at -32C. Piping from heat exchanger over a fluid connector (must be specified and put in place) for glycol transfer into trailer interior. Select pipe insulation which will maintain minimum temperature losses over distance. Trailer is 53 feet long. Interior heat exchanger (glycol to air) would be placed in center ceiling of container (approximately 35 feet from front. Assume electric pump will circulate glycol through system when system on. Mechanical system will be standard Carrier trailer system. Again look at catalogue specifications. Assume there will be a sharing as there was in last year’s project. Assume trailer container meets insulation specifications for refrigerated product K>=4 Assume cost of system $8,000. Operating costs $0 (no fuel; no service). Mechanical system cost $20,000, diesel consumption 8 l/hr;maintenance and service about $5,000 per year Attachment 2 Assumption Impact Reasoning For the first driving phase, the truck’s cargo is cooled entirely by the LNG system (if supported by calculation later) The mechanical system energy requirements only begin after the door is first opened; a significant amount of energy is saved The truck is assumed to be pre-cooled as it is, and the LNG consumption is only given The mechanical system begins cooling only after the temperature has fallen out of spec after the first stop 38 OF for the fridge) Minimize energy consumption via the mechanical system More realistic application of the mechanical system. Also, the fact that it will minimize energy consumption was a reason in making this assumption Assumption Impact Reasoning The cargo was pre-cooled to the specified temperatures 38 OF for the fridge) Simplifies the process and minimizes energy requirements of the mechanical system Instructions per sponsor LNG is always on when truck is running Minimizes energy requirements of the mechanical system Maximizes use of the LNG system (whose sole purpose is to reduce the use of the mechanical system) Both mechanical heat exchangers have constant cooling loads equal to the maximum ambient heat experienced by each compartment with the door closed. The ambient heat was calculated based on full exposure to ambient on each compartment except for the partition, which bleeds heat into the freezer. Calculated heat gains for compartment is 1135 W (based on 26K difference) for the fridge Simplifies the calculations made for transient air temperature within the freezer. With these values the mechanical system should be barely able to sustain the specified temperatures and thus require more use of the LNG system Walls maintain constant temperature (within each compartment Simplifies the process/reduces calculations Instructions per sponsor Pallets are 40” x 48” Volume occupation of the produce within the trailer Standard size of pallets Pallets are pushed against the wall farthest from the trailer door and span the length of the compartment Simplifies area exposure for temperature calculations Instructions per sponsor The temperatures of the cargo are non-changing Simplifies heat profiles With the heat capacities being at least 3 times that of air, we assume the temperature of each cargo will not change drastically Assumption Impact Reasoning The fridge air temperature remains constant (assuming our controller for the LNG can ensure this) Simplifies term dependence From calculations so far, the temperature of the fridge will not change drastically from the opening and closing of the door pallets are removed instantaneously (fork lifts) Removes transient calculations Instructions per sponsor All heat exchangers within the trailer are 100% efficient Simplification Expectations are that the heat exchangers should not vary greatly from 100% / instructions per sponsor Start-up after each stop is ignored; the glycol flow initiation is instantaneous Removes transient calculations Assumption that the transient time of operation will be insignificantly small relative to the overall operation time Opening and closing the door is instantaneous Removes transient calculations Again, assumption that the time to open and close the door are small relative to overall operation The fridge door is perfectly sealed in that they possess the same insulation as the rest of the trailer when closed Simplifies the ambient heat gain Assumption that existent leaks will be relatively insignificant When the door is opened, the extra heat transfer is treated as solely conduction; the “thickness” of the air boundary layer is 0.051m (2”) Affects temperature gain of the freezer air Instructions per sponsor / two inches was arbitrarily seen as reasonable in the thickness of the rest of the trailer walls, so the same thickness was applied here Average speed of travel is 55 mph for long trip 30 mph for short trip Fuel consumption of LNG Made based on highway speeds with many stops (stoplights, stop signs, turns, etc.) Attachment 3-European performance test for Direct Injection LIN Calculations for: K 0.4 W / m 2 deg , temperature in trailer Tin 20 C , outside temperature Tout 30 C , trailer total surface area F 155 m 2 . The heat influx into trailer through its heat insulation is: Qin K F T 0.4 155 50 3100 W . The heat influx to liquid nitrogen in the pipe, supplying it into trailer, is: Qtu = 133 W. So, the total heat, which is to be absorbed by our system, is: Q Qin Qtu 3100 W 133 W 3233 W . 1 gram of liquid nitrogen absorbs during vaporization q 1 190 J ; 1 gram of generated vapor, under condition that it is heated in trailer to temperature by 10 degree less than Tin , absorbs q2 174 J . So 1 gram of liquid nitrogen absorbs totally in the trailer q q1 q2 190 174 364 J . The total liquid nitrogen consumption is: G Q / q 3233 / 364 8.88 g / s 32 kg / hour . The following table shows time of operation of different systems depending on the amount of liquid nitrogen stored in the system vessel (or vessels): Volume of nitrogen, l 650 1000 1300 Mass of nitrogen, kg 520 800 1040 Time of operation, h 25 32 16 These results were obtained under condition, that heat influx into trailer from its surrounding, during filling the system vessels with liquid nitrogen, was taken into account. And we remind that consumption of liquid nitrogen is equal to 32 kg/h. Calculations for: K 0.36 W / m 2 deg , the other of initial data being the same. This time the table of results is as follows: Volume of nitrogen, l 650 1000 1300 Mass of nitrogen, kg 520 800 1040 Time of operation, h 27 35 17 The consumption of liquid nitrogen this time is equal to 29 kg/h. Attachment 4 LNG Truck configuration with mechanical system Attachment 5 LNG Truck configuration with LIN system Attachment 6 LNG tractor-trailer configuration with mechanical system