ME444-Assignment #4-Sol

advertisement

ME444-Assignment #4-Sol

1.

October 16, 2014

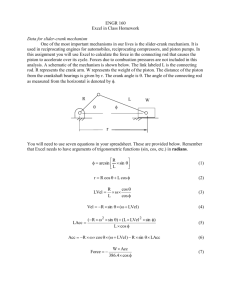

Considering below picture with a connecting rod length of 𝑙, crank shaft radius of r and a

piston pin offset of d, one can derive the expression for “Displacement”, “Velocity” and

“Acceleration”.

𝑥 = 𝑟 cos(𝜃) + √𝑙 2 − (𝑟 sin(𝜃) − 𝑑)2

𝑙

𝑟 2

𝑑 2

√

= 𝑟 [cos(𝜃) +

1 − ( ) (sin(𝜃) − ) ]

𝑟

𝑙

𝑟

Taking a derivation from 𝑥 respecting 𝑡, we can get:

𝑣=

𝑑𝑥 𝑑𝑥 𝑑𝜃

=

𝑑𝑡 𝑑𝜃 𝑑𝑡

1

ME444-Assignment #4-Sol

October 16, 2014

𝑟

𝑑

( ) cos(𝜃) (sin(𝜃) − 𝑟 )

𝑙

= −𝑟𝑤 sin(𝜃) +

2

2

√1 − (𝑟) (sin(𝜃) − 𝑑 )

[

𝑟 ]

𝑙

And finally taking a derivation from 𝑣 respecting 𝑡, we can get:

𝑎=

𝑑𝑣 𝑑𝑣 𝑑𝜃

=

𝑑𝑡 𝑑𝜃 𝑑𝑡

𝑟

𝑑

𝑟 3

𝑑 2

( ) [(cos(𝜃)2 − sin(𝜃)2 ) + 𝑟 sin(𝜃)] ( ) cos(𝜃)2 (sin(𝜃) − 𝑟 )

cos(𝜃) + 𝑙

+ 𝑙

= −𝑟𝑤 2

[

2

2

√1 − (𝑟) (sin(𝜃) − 𝑑 )

𝑟

𝑙

2

2

√(1 − (𝑟) (sin(𝜃) − 𝑑 ) )3

]

𝑟

𝑙

Results of calculations regarding the assumptions of the problem have been plotted using

a MATLAB Code (the code has been brought I the appendix).

Displacement-Crank angle

2

ME444-Assignment #4-Sol

October 16, 2014

Velocity-Crank angle

Acceleration-Crank angle

3

ME444-Assignment #4-Sol

October 16, 2014

Why might one design an offset?

The piston and its half of the connecting rod stops twice per crankshaft revolution, even

though the crankshaft continues to turn. This means the piston and top of the rod also start

back up twice. This stopping and starting imposes stresses on all three of the parts, stresses

that increase with crankshaft rpm. To reduce these loads, the piston is mounted to the

connecting rod slightly offset. This causes the piston to reach top dead center at a different

time than the connecting rod, effectively spreading the shock loading over a greater number

of crankshaft degrees. In short, the real reason for piston pin offset is that it softens reciprocal

loading, permitting lighter more power-efficient parts to be used, and the engines to be

capable of higher rpm.

However, there is another phenomenon at work also, a kind of side benefit. Because the

connecting rod spends most of its time in the engine at an angle, the piston engine has what

is called minor and major thrust. Major thrust refers to the downward-stroking piston's force

against the cylinder wall during combustion, due to the rod being angled in that direction.

Minor thrust is the piston's thrust against the opposite cylinder wall during compression,

because the rod's angle is opposite also. These thrust forces push the piston firmly against

the cylinder wall. The important thing is that at TDC, they flip-flop. Major thrust turns into

minor thrust, and visa-versa. In older engines, this flip-flop caused the piston smack the

cylinder, resulting in a noise. Fortunately, the piston pin offset in today's engines, besides

reducing inertia stresses, does two things that reduce this noise. First, because the piston is

mounted off center, the transition from major to minor thrust is less sudden. There is less

impact. Second, instead of a sudden lateral shift, the piston actually rolls from major to minor

thrust. That is, the piston shifts first at the skirt, then gradually the rest of the piston makes

contact, instead of all of the piston at once.

To summarize, piston pin offset is the manufacturer's way of reducing stress on reciprocating

parts. It permits these parts to be lighter, which results in more efficient manufacture and

less power loss in the engine, as well as higher rpm. A complementary result of piston pin

offset is reduced piston slap due to the more gradual shift from major to minor thrust [1].

4

ME444-Assignment #4-Sol

2.

October 16, 2014

Cam-phasing VVT is the simplest, cheapest and most commonly used mechanism at this

moment. However, its performance gain is also the least, very fair indeed.

Basically, it varies the valve timing by shifting the phase angle of camshafts. For example,

at high rev, the inlet camshaft will be rotated in advance by 30° so to enable earlier intake.

This movement is controlled by engine management system according to need, and

actuated by hydraulic valve gears.

Note that cam-phasing VVT cannot vary the duration of valve opening. It just allows earlier

or later valve opening. Earlier opening results in earlier closing, of course. It also cannot vary

valve lift, unlike cam-changing VVT. However, cam-phasing VVT is the simplest and cheapest

form of VVT because each camshaft needs only one hydraulic phasing actuator, unlike other

systems that employ individual mechanism for every cylinder.

Continuous or Discrete:

Simpler cam-phasing VVT systems offer just 2 or 3 fixed phasing angles, such as either 0° or

30°. Better systems can vary phase angle continuously. Obviously, this provides the most

suitable valve timing at any rev, thus greatly enhance engine flexiblility. Moreover, the

transition is seamless and hardly noticeable, contributing to refinement. Today, continuous

systems have put discrete systems in extinction.

Intake and exhaust:

Some designs, such as BMW's Double-Vanos system, has cam-phasing VVT at both intake and

exhaust camshafts. This enables more overlapping, hence higher efficiency. This explain why

BMW M3 3.2 (100hp/litre) is more efficient than its predecessor, M3 3.0 (95hp/litre) whose

5

ME444-Assignment #4-Sol

October 16, 2014

VVT is bounded at the inlet valves. In the E46 3-series, the Double-Vanos shifts the intake and

exhaust camshaft within a range of 40° and 25° respectively [2].

The effect of “Cam Phasing” in the PV diagram:

6

ME444-Assignment #4-Sol

October 16, 2014

Reference:

[1] http://www.motorcycleproject.com/motorcycle/text/cows-offset.html

[2] http://www.autozine.org/technical_school/engine/vvt_3.htm

7

ME444-Assignment #4-Sol

October 16, 2014

Appendix A

clc

clear all

prompt = {'Enter the Piston Stroke (mm):','Enter the Connection Rod Length

(mm):',...

'Enter the first Piston Pin Offset:','Enter the second Piston Pin

Offset:','Enter the Crank Rotational Speed (RPM):'};

dlg_title = 'Input1-Family Sedan';

num_lines = 1;

def = {'85','130','2','10','2200'};

answer = inputdlg(prompt,dlg_title,num_lines,def);

PSt=str2num(answer{1});

L=str2num(answer{2});

D1=str2num(answer{3});

D2=str2num(answer{4});

N=str2num(answer{5});

r=(PSt*0.001)/2;

l=L*0.001;

d1=D1*0.001;

d2=D2*0.001;

N=N/60;

d=d1;

[ teta , x , v , a ] = cal( r , l , d , N )

x1=x;

v1=v;

a1=a;

d=d2;

[ teta , x , v , a ] = cal( r , l , d , N )

x2=x;

v2=v;

a2=a;

plot((teta*180)/pi,x1,'--b',(teta*180)/pi,x2','r','LineWidth',2);

grid on

xlabel('teta(degree)');

ylabel('Displacement (m)');

legend('offset = 2 mm','offset = 10 mm)')

figure

plot((teta*180)/pi,v1,'--b',(teta*180)/pi,v2','r','LineWidth',2);

grid on

xlabel('teta(degree)');

ylabel('Velocity (m/s)');

legend('offset = 2 mm','offset = 10 mm)')

figure

plot((teta*180)/pi,a1,'--b',(teta*180)/pi,a2','r','LineWidth',2);

grid on

xlabel('teta(degree)');

ylabel('Accelaration (m/s^2)');

8

ME444-Assignment #4-Sol

October 16, 2014

legend('offset = 2 mm','offset = 10 mm)')

function [ teta , x , v , a ] = cal( r , l , d , N )

teta=0:(10*pi)/180:(2*pi);

A=sqrt(1-(r/l)^2*(sin(teta)-d/r).^2);

w=2*pi*N;

x=r*(cos(teta)+(l/r)*A);

v=-r*w*(sin(teta)+((r/l)*cos(teta).*(sin(teta)-d/r))./A);

a=-r*w^2*(cos(teta)+(r/l)*((cos(teta).^2sin(teta).^2)+(d/r)*sin(teta))./A+(r/l)^3*cos(teta).^2.*(sin(teta)d/r).^2./A.^3);

end

9