Star refrigeration acknowledges that health and safety hazards may

advertisement

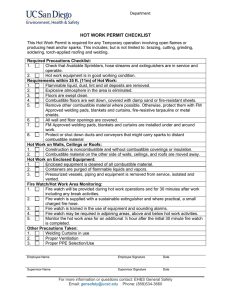

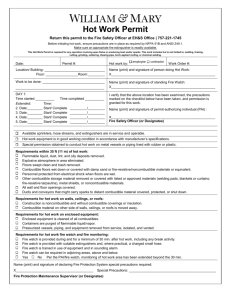

SAFETY GUIDANCE HOT WORK AWAY SG024.01 Page 1 of 2 It is a condition of the Star Refrigeration Group insurance policy that the precautions set out below shall be fully complied with on every occasion where Star Refrigeration Group employees, or subcontractors working for the Star Refrigeration Group, are engaged in Hot Work away from Star Refrigeration Group premises. Managers, supervisors, engineer-in-charge or, where appropriate, the senior sub-contractor representative must ensure that all the rules in this policy are carried out and must either implement the control measures themselves or appoint a suitably qualified individual as the responsible person to implement the control measures. Hot Work includes using a naked flame or other heat source including but not limited to:a. b. c. d. Oxyacetylene and other oxy-fuel; or electric arc or similar welding, cutting, grinding or other spark emitting equipment; or blow lamps; or otherwise applying heat The Hot Work Area shall mean an area of space within a Six (6) metre radius vertically as well as horizontally of any Hot Work. Rules applicable to all Hot Work away from Star premises: a) Before Hot Work is commenced, the occupier of the premises must be informed of the proposed safety precautions and asked for specific authority to proceed. A Hot Work Permit is to be completed by the responsible person either in the Star Standard Form SF.820 or in a similar form provided by the occupier, providing that the completion of the Hot Work Permit does not vary or waive any of the rules below. It is not desirable to issue permits for protracted periods. The maximum duration of a permit shall be one normal shift. b) The Hot Work Area is to be examined and cleared of loose combustible or flammable material or liquids by the responsible person. If such combustible material or liquids cannot be removed they should be protected with flameproof covers such as overlapping fire blankets or sheets of non-combustible material. Floors, walls, insulation panels, pipe insulation, ceilings, roofs, ducts and partitions made of combustible material are also to be protected with flameproof covers. Openings in floors walls ceilings roofs or ducts within the Hot Work Area are to be closed, covered, sealed or otherwise rendered impervious to the passage of fire. c) Before applying heat to metal or other conducting material such as pipework and pipe supports, which is built into or projects through walls, partitions, cavities, ceilings, floors, roofs or ducts, an examination is to be made by the responsible person to ensure that there is no combustible material in hazardous proximity to such metal or conducting material, e.g. on the opposite side from the hot work, which may be ignited by direct or conducted heat. d) No Hot Work is to be carried out i. in atmospheres which are potentially explosive through the presence of vapours or dusts ii. in areas where flammable fluids and/or flammable materials are not totally enclosed or where processes incorporating the same are not shut down Page 2 SG024.01 Hot Work iii. of 2 on metal or other conducting materials in contact with combustible walls partitions cavities ceilings floors roofs or ducts if close enough to cause ignition by conduction or direct heat e) Throughout the period of Hot Work and throughout the period of examination after termination of work referred to in precaution (i) There shall be a hose connected to a source of water supply (which must be turned on) of suitable volume and pressure and with a controllable nozzle at the outlet and of sufficient length to permit a fire at the job location to be tackled from any angle OR two (2) fully charged (9 Litre) water fire extinguishers within a radius of 6 metres.. In addition to water or water extinguishers, occasionally, it may be appropriate to have other types of extinguisher available when specific risks are identified in the area. f) All those engaged in the Hot Work shall be made aware of the location of the site’s fire alarms and fire fighting equipment. g) Accompaniment is a strict requirement during hot work therefore a responsible employee of Star, its sub-contractor or of the occupier of the premises shall be appointed to work alongside the operator of the equipment to look out for an outbreak of fire. h) All fire protection controls must remain effective during the period of Hot Work. Such fire protection controls are to include but not be limited to fire doors being closed sprinkler systems remaining operable and where there is a risk of explosive atmospheres forming, ventilation must be maintained whilst ensuring this does not promote fire spread. i) A thorough examination is to be made in and about the Hot Work Area including behind walls, partitions, ceilings, roofs or floors regularly during operations. The same examination is to continue for a minimum of 60 minutes after any termination (including breaks) of Hot Work before the Hot Work Area can be left unattended. After this period, the issuer should sign off the permit - retain a copy. j) Hot Work equipment when lit or naked flames shall never be left unattended for any period of time. k) Blow lamps and blow torches shall only be filled in the open l) Gas cylinders not required for immediate use shall be kept at least six (6) metres from where the heat is being applied. Leak detectors with naked flames Leak detectors must never be left unattended once lit. They are only to be filled, or their cylinders changed, in the open. General Housekeeping It is unacceptable to have loose combustible material around a working refrigeration plant at any time. Date 09/12/11 Issue 00 01 Changes Revised in accordance with new requirements of QBE heat warranty to include water hose or two fully charged extinguishers Originator CJH CJH