DOC - Cyrus Energy

Cyrus

Eradicate

Product Analysis

Report

Dr Eve Bird

Cyrus Eradicate Product Analysis Report

Overview of Project

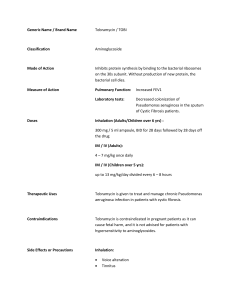

Cyrus Energy Ltd. market a number of fuel additives, one of which is the diesel biocide Cyrus

Eradicate. Microbial contamination of diesel storage tanks and pipework is a widespread and potentially costly issue, prevention (and intervention) of infection can be achieved by routine use of a fuel biocide.

Pseudomonas aeruginosa ATCC 33988, originally isolated from a fuel storage tank (Ponca City,

Oklahoma) was chosen to test the efficacy of Cyrus Eradicate, as P. aeruginosa is one of the microorganisms most often implicated in founding the multi-species biofilms associated with severe diesel contamination (Rossmoore, et al., 1988). The normal pattern of fuel tank colonisation begins with a founder species such as P. aeruginosa, an aerobic bacteria, that alters the pH and oxygen level of the microenvironment to such an extent that other species (such as anaerobic sulphate reducing bacteria or pH sensitive fungi) may flourish. Additionally P. aeruginosa ATCC 33988 is utilised by the

US Department of Defence as the organism of choice for biocide challenge testing (Interim Report

MIL-S-53021, 1993).

Cyrus Energy Ltd. were aware that Cyrus Eradicate worked but did not have the test data to confirm:

The concentration of Cyrus Eradicate required to exterminate P. aeruginosa contamination in diesel.

The time Cyrus Eradicate takes to reduce / eliminate viable P. aeruginosa in diesel.

Obtaining this information would enable product validation, consumer confidence in the product and product development.

Assessment of the background microflora in diesel

Preceding biocide efficacy testing, an assessment of the background microflora present in the unsterile diesel sample was conducted. This assessment was done to ascertain the degree of background microflora and whether a sterilisation pretreatment was required to ensure consistent results.

A selection of agar plates: Nutrient agar (NA), Malt extract agar (MEA), Clostridial agar (CA) and

Pseudomonas agar (PA) were prepared according to the manufacturer’s (Oxoid, Hampshire, UK) instructions, and sterilised by autoclave at 121°C for 15 minutes.

Neat diesel (200 μl) was spread onto five of each variety of agar plate (NA, MEA, CA & PA). The sets of plates were then incubated under five different conditions and checked periodically over 14 days to observe if any microbial growth was present. The conditions the plates were incubated under were: aerobically at 17°C, ambient room temperature, 37°C and 50°C and anaerobically at 30°C.

Table 1: Assessment of the background microflora in diesel aerobic

17°C aerobic

Room aerobic

37°C aerobic

50°C anaerobic

30°C

NA

1 white fungi (green / brown underside), filiform margin

3 small white circular colonies, raised elevation, entire margin

2 small white circular colonies, raised elevation, entire margin

No visible growth

No visible growth

MEA

1 large white fungi (black in the centre), dark underside, filiform margin

1 large white fungi (green / brown underside), filiform margin

No visible growth

CA

No visible growth

No visible growth

No visible growth

No visible growth

No visible growth

No visible growth

No visible growth

PA

No visible growth

1 small white / pink small circular colony, raised elevation, entire margin

4 small white / pink small circular colonies, raised elevation, entire margin

No visible growth

No visible growth

Conclusion:

Due to the negligible background microbial contamination of the diesel sample, it was decided that the diesel did not require any pre-treatment to remove background organisms, as the minimal microflora present would not significantly interfere with the biocide efficacy testing. All glassware will be sterilised prior to addition of diesel to ensure any contamination is introduced to the test via the diesel can or diesel.

Determination of the efficacy of Cyrus Eradicate against Pseudomonas aeruginosa

The recommended dosage of Cyrus Eradicate is 1:2000. An overnight culture of P. aeruginosa was prepared and washed as described below and used to inoculate (low, 100 μl; high 400 μl) eight test bottles of diesel (100 ml).

Materials

Glass bottles (250 ml with PTFE-lined screw caps)

Magnetic stirrers *1 for each bottle*

Nutrient agar (NA) plates *8 per test bottle/per sample point*

Nutrient broth (NB)

Buffer

Microcentrifuge tubes

Beaker (250 ml)

Measuring cylinder (250 ml)

Vortex mixer

Magnetic stirrer plate

Plate counter

Method

0.

Prepare media and materials.

A) Make up buffer, NB and NA plates.

B) Sterilise beaker, buffer, microcentrifuge tubes, measuring cylinder, glass bottles

(containing magnetic stirrer).

C) Aseptically aliquot 900 µl of buffer into individual centrifuge tubes (for dilution series).

D) Aseptically add 100 ml of diesel to sterile glass bottles.

1.

Revive culture and grow on NA plates.

2.

Subculture isolated colony on a NA plate.

3.

Subculture into NB incubate overnight.

4.

Wash cells.

A) Aliquot 45 ml of overnight culture into sterile centrifuge tubes.

B) Centrifuge at 12,000 rpm for 10 minutes.

C) Discard supernatant.

D) Add 5 ml of sterile buffer.

5.

Inoculate washed cells into diesel (low = 100 μl / high = 400 μl).

Take plate count (Day 1, pre-biocide).

A) Shake bottle vigorously for 5 seconds, place on magnetic stirrer plate.

B) Remove a 100 µl sample and pipette into 900 µl of buffer vortex.

C) Perform dilution series plate out relevant dilutions onto NA plates.

6.

Add biocide to relevant bottles.

7.

Take plate count (Day 2, post-biocide).

8.

Day 3 plate count.

9.

Day 7 plate count.

10.

Record results and determine the CFU/ml.

Results

Table 2: The efficacy of Cyrus Eradicate in diesel inoculated with P. aeruginosa (CFU/ml)

1

P. aeruginosa low inoculum + biocide

2

P. aeruginosa

High

3

P. aeruginosa low

4

P. aeruginosa high

5

P. aeruginosa low

6

P. aeruginosa

+ high

7

P. aeruginosa low inoculum

8

P. aeruginosa high inoculum

1 in 1000 inoculum + biocide

1 in 1000 inoculum + biocide

1 in 2000 inoculum + biocide

1 in 2000 inoculum +

biocide

1 in 4000 inoculum + biocide

1 in 4000

1.72E+04 2.32E+04 2.31E+04 1.26E+05 1.34E+05 1.22E+05 1.52E+05 2.48E+05 Prebiocide

24 hours 0.00E+00 0.00E+00 0.00E+00 2.00E+01 3.50E+01 8.00E+01 1.25E+05 9.45E+05

48 hours 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 2.30E+05 1.71E+06

144 hours

0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 3.05E+06 1.31E+07

Chart 1: The efficacy of Cyrus Eradicate on P. aeruginosa in diesel (CFU/ml)

1,00E+08

1,00E+07

1,00E+06

1,00E+05

1,00E+04

1,00E+03

1,00E+02

1,00E+01

Biocide 1 in 1000

Biocide 1 in 1000

Biocide 1 in 2000

Biocide 1 in 2000

Biocide 1 in 4000

Biocide 1 in 4000

No biocide

No biocide

1,00E+00

Day 2 Day 3 Day 4

Hours

Day 6 Day 7

Conclusions and future work:

Cyrus eradicate is active against P. aeruginosa at half the recommended dosage (1 in 4000).

At high concentrations (1 in 1000) Cyrus Eradicate eliminates all microorganisms from the test flasks within 24 hours. At lower concentrations (1 in 2000, 1 in 4000) complete eradication of viable P.

aeruginosa was not seen until 48 hours later.

Future work recommended for this project would involve co-contamination of diesel with a consortium of diesel degrading organisms, to ensure that the biocide has the ability to remove established contamination consisting of a multi-species biofilm at low concentrations. There does not appear to be a consensus standard method published for enumerating filamentous fungi, which are known to join the consortium of organisms which can infect diesel. Unlike with bacterial species, methods relying on direct counts of colony forming units have been found to be unacceptable, as the estimation does not correlate well to the actual contamination present (Gaylarde et al., 1999). A potential future project the Biofuel Research Centre could undertake would be to develop a new method for enumerating a multi-species contamination within diesel.

Gaylarde, C. C., F. M. Bento & J. Kelley (1999) Microbial contamination of stored hydrocarbon fuels and its control. Revista de Microbiologia 30:1-10.

Interim Report MIL-S-53021 (1993) Compatibility and efficacy of biocides qualified under military specification MIL-S-53021. Interim Report BFLRF No. 282. S.R. Westbrook, Belvoir Fuels and

Lubricants Research Facility (SwRI), Southwest Research Institute, San Antonio, Texas and M.L.

Alexander, Southwest Research Institute, San Antonio, Texas.

Rossmoore, H. W., J. W. Wireman, L. A. Rossmoore & V. F. Riha (1988) Factors to consider in testing biocides for distillate fuels. Distillate Fuel: Contamination, Storage and Handling. ASTM STP 1005, H.

L. Chesneau and M. M. Dorris, Eds., American Society for Testing and Materials, Philidelphia, pp.95-

104.

Glossary of scientific terms

Pseudomonas aeruginosa

Pseudomonas aeruginosa is a Gram negative aerobic (oxygen utilising) bacteria. P. aeruginosa is ubiquitous in the environment; it is an extremely metabolically diverse organism which can adapt to live in many different environments (ranging from the human body to diesel tanks).

Inoculum

Inoculum is the starting bacterial suspension introduced into the test media.

Biofilm

Biofilms are complex structures adhering to a surface consisting of colonies of bacteria (and usually other secondary microorganisms such as yeasts, fungi, and protozoa) that secrete a mucilaginous protective coating in which they are encased.