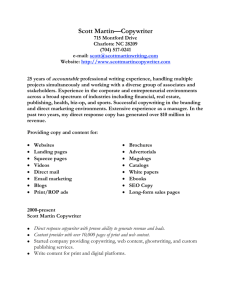

2-page Sample Resume for Experienced

advertisement

WILLIAM J. NINER 123 University Drive, Charlotte, NC 28207 ♦ (704) 555-5555 ♦ wjniner@aol.com ♦ https://www.linkedin.com/in/niner PROFILE: Technically sophisticated Mechanical Engineer with over 15 years of experience in the management, design, and delivery of mechanical systems and devices in numerous industries. Track record of waste and cost reductions, system enhancements, and process improvements arising from expertise in Lean Manufacturing and related techniques. Proven ability to motivate and engage top performance from multidisciplinary teams to consistently surpass company goals. TECHNICAL EXPERTISE: Programming Languages Visual Basic PanelBuilder 32 AutoCAD AB 6200 Oracle SQL and PL/SQL Deflection Calculator RS Logix 500 Device Net Certifications UL Certification ISO Auditor Certification UNIX Programming JavaScript C++ Programming UltraWare EXPERIENCE: SELF EMPLOYED, Charlotte, NC 2010 - present Engineering Consultant Consult with companies in the construction, manufacturing, and aerospace industries to define needs, establish project parameters, and propose technical solutions that meet company objectives. Design, develop, and test prototypes to improve production and comply with product regulation specifications. Key Project Highlights: ABC AEROSPACE CORPORATION, Charlotte, NC (2014 – present) Developed Hydraulic Troubleshooting Procedures to implement into the Vehicle IETM that optimized maintenance protocols. Designed drawings on multimillion-dollar projects including tank line cranes and underhung cranes. Rolled out industry’s first hoist-operated tail dock crane, meeting strict specifications and coming in 10% under budget. DEF MANUFACTURING COMPANY, Richmond, VA (2013 – 2014) Cut production costs by 14% by designing electrical and electro/pneumatic control panels for automation and handling equipment. Improved response time by 10% on QC alert of trending rejects. GHI, INC., Cleveland, OH (2010 – 2011) Lowered steel fabrication cost by 30% annually by developing stricter quality control standards and improved training processes to reduce excessive labor and waste. Consolidated many operational functions into one entity, a result of imposed downsizing, saving 12% on labor cost. JKL COMPANY, Charlotte, NC 2007 - 2010 Senior Project Engineer Led the design and operations management of electrical control panels and servo control systems for automation and handling equipment. Managed daily client relationships with over 25 companies. WILLIAM J. NINER Page 2 JKL COMPANY (continued) Key Accomplishments: Launched and oversaw ISO and UL safety compliance standards and procedures, instructing and monitoring cross-functional teams on protocol adherence. Utilized ERP, Excel, and related software systems to administer product lifecycle production schedules, facilitating smooth operations and increasing efficiency by 22%. Trained dozens of clients by creating client instruction manuals providing/describing BOM, schematics, testing procedures, and operational cycles. MNO COMPANY, Charlotte, NC 2001 - 2007 Mechanical Engineer (2004 – 2007) Assisted in all phases of the product-development lifecycle, from conceptualizing new product lines through sketching, designing models, developing engineering blueprints, prototyping, testing, supporting production, and rolling out new products. Key Accomplishments: Conducted modeling, simulation and analysis of structural components using CAD techniques, Creo Elements/Pro and Abaqus FEA Suite that rolled out product 3 months earlier than target date. Led interdisciplinary teams to resolve production, distribution, and pricing issues. Mechanical Designer (2001 – 2004) Provided mechanical engineering support to the product-development team for one of the country’s fastestgrowing underwater LED lighting manufacturers. Key Accomplishments: Contributed to the successful release of two LED anchor-masthead and three LED underwater lighting products. Ensured safety by defining strict guidelines for prototypes, installation, and consumer use. PRESENTATIONS/PUBLICATIONS: Niner, W. V. “The utilization of ERP to accurately administer and standardize product lifecycle production schedules,” Institution of Mechanical Engineers National Conference, Chicago IL, September 2014. Butananon, L. L., and Niner, W. V. “Heat transfer and stress analysis in LED lighting component structures,” Journal of Mechanical Design, Vol. 1, No. 1, 2008. Jones, J. P., and Niner, W. V. “Effects of moisture exposure on hydrodynamic characteristics of MEMS based heat exchanger with different test fluids,” Journal of Applied Science, Vol. 6, No. 2, 2001. PROFESSIONAL ASSOCIATIONS: American Society of Mechanical Engineers ♦ Institution of Mechanical Engineers EDUCATION: Master of Science, Technological Systems Management Southern Arkansas University, Arkansas, AR 2001 Bachelor of Science, Mechanical Engineering University of North Carolina at Charlotte, Charlotte, NC 1998