(RO) 500 LPH WATER PURIFYING SYSTEM,WATER DISPENSERS

advertisement

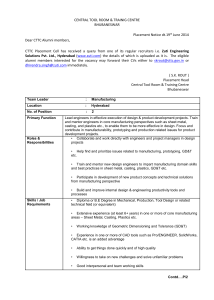

STATE BANK OF HYDERABAD TENDER FOR SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM,WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD TECHNICAL BID Last date for submission of Sealed Tender: 16TH APRIL 2012 Before 3.00 PM on Opening of Sealed Tenders: At 4.00PM on 16TH APRIL 2012 Tender to be submitted to: State Bank of Hyderabad, ESTATES DEPT Head Office, Gunfoundry, Hyderabad – 500 001. Phone – 040 – 23387212/220 Name of the Contractor to whom issued: ________________________________________________ ________________________________________________ ________________________________________________ ____________________________________________ SIGNATURE OF CONTRACTOR -2- NOTICE INVITING TENDER (NIT) Name of the work: SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM, WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD I Sealed tenders are invited FROM REPUTED FIRMS SPECIALISED IN WATER TREATMENT WORKS. 1 Name of the work 2 3 4 5 6 7 8 9. Cost of application/ tender document. Tenders may be downloaded from the banks web site “www.sbhyd.com/tenders.asp” free of cost. Date and Time where tender forms are available for sale. (From_________to_________) Details of web site: Time and last date of Submission of Tender Place & Address for submission of tender/ contact person/telephone no/ Date, Time and Place of opening of tenders (tech.Bid on _____ Price Bid on ____). Contact person details: Name_______. Contact no:__________ Quantum of Earnest Money Deposit (EMD)Rs____ drawn in favour of CHIEF MANAGER ESTATES DEPT., HO_______payable at HYDERABAD. Quantum of Security Deposit Rs______(percentage) drawn in favour of _______payable at ____________. Amount of Bank Guarantee. TENDER FOR SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM, WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD FREE OR TENDER COST WAIVED. UP TO 3.00 PM ON 16/04/2012 Web site details: www.sbhyd.com AVAILABLE IN BANK’S WEBSITE, MAY BE DOWN LOADED DIRECTLY AT FREE OF COST. Up to 4.00 PM 16/04/2012 CHIEF MANAGER, ESTATES DEPARTMENT, , STATE BANK OF HYDERABAD, HEAD OFFICE, 2ND FLOOR, GUNFOUNDRY BUILDING, GUNFOUNDRY, HYDERABAD 500001. 040 23387212/220 Technical Bid AND Price Bid on 15/03/2012 4.00PM. CONTACT PERSON:SRI.B.DHEERENDRA, MANAGER ESTATES DEPARTMENT TEL : 23387220 & 23387212 Rs,15,000/- (RupeesFifteen thousand only) ---- Terms of payment of Bills, if any. Specify the minimum value of work for payment of running account bills. 1)100% payment towards Supply, Delivery, Installation & Commissioning of RO plant, water dispensers & water cans 2)Operation & Maintenance charges (AMC) should be paid on monthly basis 10 (penalty clause)Liquidated Damaged 11 Stipulated time for completion of the work/supply. -NOT APPLICABLE- 12 Estimated Value of the Tender Estimate of RO Plant & other items : Rs.7.15 lacs Estimate of O&M for two years :Rs.7.15 lacs ------- Total Estimate Contract Value:Rs.14.30 lacs 13 Validity period of the tender. 14 Taxes ----Rates quoted should include all Taxes, Octroi vat other charges like Transportation etc. However I.T and WCT will be deducted at source. Electronic payment only be made. All the contractor must furnish details such as 1) Name of the their bank 2) Name of their branch 3) Account number 4) Name of the account holder as in the bank account 5) IFSC code of the branch 6) Sales Tax regn number 7) Pan number. 15 Electronic Payment 15 days The bank reserves the right to cancel or postpone the tenders at any stage without assigning any reason. ASST. GENERAL MANAGER (ESTATES) 4TECHNICAL BID STATE BANK OF HYDERABAD ESTATES DEPARTMENT HEAD OFFICE, HYDERABAD. Sealed tenders are invited from competent contractors/ firms who can SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM, WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD 1.NAME OF THE WORK SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM, WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD 2. DETAILS OF INTENDING CONTRACTOR: A) Name : B) ADDRESS : C) TELEPHONE NO. : D) CONTACT PERSON :_________________________ 3. COST OF TENDER SCHEDULE 4. EMD DETAILS : FREE OF COST. APPLICATION CAN BE DOWN LOADED FROM BANK’S WEBSITE. : 5. LAST DATE FOR SUBMISSION OF TENDER : BEFORE 15.00 HOURS ON 16/04/2012 6. PERIOD OF START OF WORK : Within 5 days from the date of receipt of work order. In case of work not being started within stipulated period the bank reserves the right to cancel the work order duly forfeiting the EMD. 7. PERIOD OF CONTRACT 8. ESTIMATED COST ; TWO YEARS FROM DATE OF ISSUE OF WORK ORDER : Estimate of RO Plant & other items: Rs.7.15 lakhs Estimate of O&M for two years : Rs.7.15 lakhs -- Total Estimate Contract Value: Rs.14.30 lakhs : A) The bank reserves the right to accept or reject any or all applications. 09.Municipal water to be filtered through the plant setup at Head Office (fifth floor- terrace). 10. The validity of the tender is only for three months period. 11. Any claim afterwards will not be accepted by the bank. 12. The vendor should be able to show the technician to the officials of the Bank. 13. Purified/filtered water to be supplied to all user departments (60) at Head Office, five floors and at Prabhat Towers (Opp. To HO) consisting of three floors. 14. PAYMENT SYSTEM: 1)100% payment towards Supply, Delivery, Installation & Commissioning of RO plant, Water dispensers & water cans 2) Operation & Maintenance shall be paid on monthly basis in 24 monthly equated installments on satisfactory certification of competent authority monitoring the AMC. 14. DEDUCTION OF TAX AT SOURCE: As applicable as per Government norms in force such as Income tax, WCT etc. 15. SERVICE TAX: Will be paid over contract value as applicable upon submission of service tax registration details as required. 16. QUALIFICATION OF PERSONS ON DUTY OF SERVICE: I) Supervisor: ITI or equivalent ii) Others : skilled labor. TECHNICAL CONDITIONS: 1. Reverse Osmosis Plant Since the Plants will be designed on the basis of Area Specific and Problem Specific, the Reverse Osmosis Plant can be used for purification of water that contains contamination like Fluoride, Brackish, Salinity, Arsenic, Nitrates, TDS, etc., The Plant comprises of the following suggestive components. However the emphasis should be suggested as per Indian Standards Norms/Specifications for the packaged purified drinking water. There should be no compromise on the quality of water and the IS: 14543-2004 permissible limits should be strictly achieved. SI No Components Purpose 1 Raw water pump To pump raw water into the inlet of multi grade/dual media /sand filter. 2 Multi grade / Dual media / Sand filter This filter is used to remove the physical impurities like turbidity, suspended solids including coarse particles, mud, sediment and sand etc., to suit the raw water quality. This filter reduces turbidity (silt) to less than 5 prescribed units to feed the R.O. Plant. 3 Activated Carbon filter This filter contains activated carbon, which removes color, smell, odor, etc., of the water. It will also remove free chlorine in feed water as it causes serious damage to the R.O. membranes. 4 Anti-scaling Dosing System Scaling accumulation (like Ca & Mg scales) on the membrane will reduce its life and production. Anti-Scaling chemical is dosed to the membrane through feed water to prevent scaling tendency on the membrane. 5 Micron Cartridge filter 6 High pressure pump to suit the plant capacity Volume of chemical added in the feed water varies on the water quality. These filters are used to remove the left over particles passed through the Sand and Carbon filters. It can be filtered up to 5 or 10 micron particle size. For effective filtration of water in the RO membrane a certain level of pressure is essential . 7 R.O Block having membranes of highest quality 8 U.V. System This pump builds up high-pressures (016kg/Cm2) and pumps the feed water to RO membrane for filtering the dissolved solids, bacteria etc. The major quantity of dissolved salts is rejected with rejected stream and almost pure water comes out as separate stream. This UV system is installed to kill the bacteria that are developed in the storage tank (if any). An ultra-violet purifier unit contains one or more germicidal ultraviolet lamps. This lamp produces ultraviolet wavelengths that are lethal to microorganisms. Approximately 95% of the ultravi8olet energy emitted is at the mercury resonance line of 254 nanometers. Their wavelength is in the region of maximum germicidal effectiveness and is highly lethal to virus, bacteria and mold spores. Therefore, the water or air that passes through he chamber is exposed to the germicidal UV light and the genetic material of the microorganism is deactivated, which prevents them form reproducing and renders them harmless. 9 Pure Water Outlet with tap points SI No Contamination To collect the pure water through the taps at the plant Raw Water Contamination Pemissible limts as per IS:14543-2004 Above 500 & Upto 5000 ppm Max 500 ppm Above 1 ppm & Upto 8 ppm 1 ppm Above 200 200 ppm Above 45 and upto 300 ppm 45 ppm Above zero Absent Above 0.05 ppm 0.05ppm Above 8.50 6.5 to 8.5 1 Total Dissolved Solids 2 Fluoride 3 Salinity (Chlorides) 4 Nitrates 5 Microbiological 6 Arsenic 7 PH 8 Turbidity Above 2 NTU 2 NTU 9 Alkalinity as CaCO3 Above 200ppm 200 ppm 10 Nitrites Above 0.05 0.05 Components of different capacities of R.O. Plants and Standards a) SCOPE OF SUPPLY SI Item No (500 LPH) 1 Raw Water pump 1 2 Multi Grade / Dual Media / Sand Filter 1 3 Activated Carbon Filter 1 4 Anti Scalent Dosing System 1 5 SMBS dosing system 1 6 Micron Cartridge Filter 1 7 High Pressure Pump 1 8 R.O.Block 1 9 4” 4040 Membranes 2 10 4” Pressure Tubes (300 psi) 4040 11 UV Unit System 1 12 Water Dispensers 50 13 Water cans 200 14 Product water SS storage tank (2000 liters) 1(2E) 1 b) INSTRUMENTATION SI Item No (500 LPH) 1 Flow Indicators 1 2 Conductivity Meter 1 3 Pressure Switch 1 4 Interconnecting piping SS/CPVC 1 Lot 5 Electric control panel 1 d) MULTI GRADE / DUAL MEDIA / SAND FILTER (500 LPH) 1. Numbers Offered 1 2. Dia (inches) 13” 3. H.O.S. 65” 4. Material of FRP Constru ction 5. Make Wave cyber/ Equivalent 6. Service Flow Rate (Its/hrs) 1500 7. Media Granual sand pebbles/ filter mesh 8. Accessories Top mounted multiport valve e) ACTIVATED CARBON FILTER (500 LPH) 1. Numbers Offered 1 2. Dia (mm) 13” 3. H.O.S. 65” 4. Material of Constr uction of IS standard FRP 5. Make Wave cyber/ Equivalent 6. Service Flow Rate (Its/hrs) 1500 7. Media Granual sand pebbles/ filter mesh 8. Accessories Top mounted multiport valve f) ANTI SCALENT DOSING SYSTEM (500 LPH) 1. Pump to suit Plant Capacity 2. Make 3. Quantity 4. Type 5. Capacity 6. Quantity of chemical tank 1 set Aqua Italy / Equivalent 1 No Electronic Diaphram Type 0 to 6 LPH 100 Litres f) SMBS DOSING SYSTEM (500 LPH) 1. Pump to suit Plant Capacity 1 set 2. Make Aqua Italy / Equivalent 1 No 3. Quantity 4. Type Electronic Diaphram Type 0 to 6 LPH 5. Capacity 6. Quantity of chemical tank 100 Litres h) MICRON CATRIDGE FILTER (500 LPH) 1. Numbers Offered 2. M O C housing 2 (Slim) 2”Dia x 20”Ht PP 3. Cartridge Rating 5 Microns 4. Cartridge Type 5. Make P.P. 0 to 6 LPH 6. Service Flow Rate (m3/hr) i) 1m3/hr HIGH PRESSURE PUMP (CE Certified) (500 LPH) 1. Numbers Offered 2. Type 1 Vertical Multi stage 3. Make 4. Service Flow Rate m3/hr 5. Head (Kg/cm2) Groundfos/ Equivalent 1 12 j) R.O. BLOCK (500 LPH) 1. No. of Blocks Offered 1 2. Product Flow Rate (Its/hr) 500 3. Feed flow (Its/hr) 1000 4. Array Structure 1:1 k) MEMBRANES (500 LPH) 1. Nos. offered (4040) 2 2. Make Trisep/ filmtecDOW-USA /Equivalent l) PRESSURE TUBES (500 LPH) 1. Nos. offered (4040) 1(2E) 2. Material of Construction FRP 3. Make Coldline/ Equivalent n) U.V. STERILISER (500 LPH) 1. Make Aquion/ Equivalent 2. Flow (Its/hr) 500 3. MOC SS o) INTER CONNECTING PIPINGS (500 LPH) 1. Pipings SS/CPCV 1 lot q) PRODUCT WATER STORAGE TANK (500 LPH) 1. Capacity 2. MOC 2000 liters SS 304 q) WATER DISPENSERS 1.Quantity 2.Make 50 No’s Blue star/ equivalant q) WATER CANS 1.Capacity 20 liters each 2.Quantity 200 No’s 2.Make Blue star/ equivalent -6- QUESTIONNAIRE TO BE FILLED IN BY THE VENDOR 1. ARE YOU HAVING A MANUFACTURING : YES/NO UNIT 2. IF YES, GIVE THE ADDRESS : 3. HAVE YOU EVER MAINTAINED : R.O. SYSTEMS IN ANY INSTITUTION : YES/NO 4. IF YES, GIVE ADDRESSES OF THE INSTITUTIONS & CERTIFICATE USER. : : 5. ARE YOU HAVING TECHNICAL MAN : YES/NO POWER TO SERVICE/REPAIR THE : R.O. PLANT. : 6.IF YES, GIVE THE NAME & DETAILS OF THE MAN POWER INCLUDING THAT OF THE SUPERVISOR TO BE CONTACTED IN CASE OF REPAIRS INCLUDING TELEPHONE NUMBER. 7.ARE YOU HAVING ISO CERTIFIED : : : : : : YES/NO 8.IF YES, GIVE THE CERTIFICATE NO : 9. ARE YOU REGISTERED COMPANY IN NSIC/SSI : YES/NO 10. IF YES, GIVE THE CERTIFICATE NO : -7- IMPORTANT TERMS AND CONDITIONS: 1. Bidders should be Manufacture Company, certificate is to be enclosed 2. Valid Registration of Name of Company with the Register of companies. 3. Valid VAT/sales tax REGISTRATION copy 4. The copy of the PAN Card of the firm. 5. Registration of Change of Name of Company with the Register of Companies, if any. 6. The Applicant must be a bonafied, technically qualified company, having experience in Engineer, Design, Manufacture, Supply, Delivery, Installation, commissioning and operation & Maintenance of water treatment plants with Reverse Osmosis technology capacity of 500 LPH and having 5 No’s of plants in a year, satisfactory performance certified by Executive Engineer an officer public sector/ sate government/Central government. 7. The applicant must be financially sound with a minimum of yearly turn over of Rs.50.00 lakhs in water treatment plants. 8. The ISO 9001 certificate is to be enclosed. 9. A self declaration certificate that the company has highly qualified & experienced technical and chemical experts handling similar type of plants. 1. If any REVERSE OSMOSIS (R.O.) WATER PURIFYING SYSTEM is not working for more than one-day amount will be deducted on pro-rata basis for the period of un serviceability. 2. The maintenance of the R.O PLANT AND WATER DISPENSERS./, is the responsibility of the vendor including replacement of spares. 3. Two work staff & one Technician should be present at the bank premises every day from 08:00 hours to 17:00 hours on all working days. They should supply water cans to all the 50 dispensers in four buildings at SBH head office premises. and report to Estates Department. 4. The application should be sent on properly sealed envelope duly enclosing all required documents and should be submitted to the Chief Manager, Estates Department, Head Office, State Bank of Hyderabad, Gun foundry, Hyderabad. 5. The firm should ensure that their quotations should reach us before the last date and time of receipt of tender. Any application received after this time for any reason what so ever may not be considered for evaluation. 6. The application should be free from overwriting, correction, additions, etc. 7. State Bank of Hyderabad reserves the right to accept or reject any application without assigning any reason whatsoever. The lowest tender may not necessarily be accepted. 8. The tender amount should be separately given for RO plant cost and two years operation & maintenance. ASST. GENERAL MANAGER (ESTATES) -8- PRICE BID SCHEDULE OF WORK TENDER FOR SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM, WATER DISPENSERS, WATER CANS AND OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD (Amt in Rs.) -----------------------------------------------------------------------------------------------------------S.NO. PARTICULARS QUANTITY RATE AMOUNT -----------------------------------------------------------------------1.SUPPLY, DELIVERY, INSTALLATION, COMMISSIONING OF REVERSE OSMOSIS (R.O.) 500 LPH WATER PURIFYING SYSTEM-1NO WATER DISPENSERS-50 NO’S AND WATER CANS-200 NO’S –ONE UNIT-2. OPERATION & MAINTENANCE, DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS IN FOUR BUILDINGS, AT SBH HEAD OFFICE, GUNFOUNDRY, HYDERABAD FOR TWO YEARS. –TWO YEARS-- ------------------------------------------------------TOTAL: ============================================================ SIGNATURE OF THE CONTRACTOR. SCHEMATIC DIAGRAM FOR RO PLANT Dosing DOSING SBH scope MICRON FILTER RAW WATER TANK RAW P S F A C F Panel BOX RO System E Pouc h M R system HIGH PR. UV U u v V PUMP REJECT WATER RAW WATERPUMP STORAGE TANK TAPS STATE BANK OF HYDERABAD ESTATE DEPARTMENT HEAD OFFICE; HYDERABAD. PH.NO. 23387220,23387212 FAX: 23387569 NO.F/TEN/ DATE : 29/02/2012 THE DEPUTY GENERAL MANAGER ITS DEPARTMENT, HEAD OFFICE, HYDERABAD. RE: DISPLAY OF TENDER NOTICE ON BANK’S WEBSITE - INSTALLATION OF REVESE OSMOSIS WATER PURIFYING PLANT AT HEAD OFFICE AND DISTRIBUTION OF POTABLE WATER TO USER DEPARTMENTS AT HEAD OFFICE, GUNFIUNDRY, HYDERABAD. -----------------------------------------------------------------------------------------------*** Please find enclosed the floppy containing the files/folders in respect of “tender notice for installation of water purifying plant and man power for water supply to user departments, at HEAD OFFICE, HYDERABAD .. We request you to arrange for uploading of the same on the BANK’S website. Please arrange accordingly. ASST.GENERAL MANAGER, (ESTATES) Encl.: As above.