Hydrothermal Synthesis of Praseodymium Strontium Titanate

advertisement

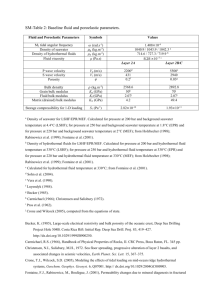

Hydrothermal Synthesis of Praseodymium Strontium Titanate Nanoparticles (El trabajo puede ser redactado en español o en inglés) Alfredo Marquez-Herrera1*, Víctor M. Ovando-Medina2, Miguel A. CoronaRivera2, Eduardo M. Lugo-Morán2 1 Departamento de Ingeniería Mecánica, Coordinación Académica Región Altiplano (COARA), Universidad Autónoma de San Luis Potosí, Carretera a Cedral KM 5+600, San José de las Trojes, Matehuala, San Luis Potosí 78700 México. E-mail: alfredo.marquez@uaslp.mx 2 Departamento de Ingeniería Química, Coordinación Académica Región Altiplano (COARA), Universidad Autónoma de San Luis Potosí, Carretera a Cedral KM 5+600, San José de las Trojes, Matehuala, San Luis Potosí 78700 México. E-mail: victor.ovando@uaslp.mx Hydrothermal synthesis refers to the synthesis by chemical reactions of substances in a sealed heated solution above ambient temperature and pressure. It involves the preparation of new materials, the understanding of mechanisms of hydrothermal reactions, and the development of novel synthetic methods and techniques. It is different from that of solid-state reactions, where the reaction mechanism involves mainly diffusion of atoms or ions at the interface between reactants. Hydrothermal synthesis is advantageous due to the relatively mild conditions required, one-step synthetic procedure and controllable particle size distribution. In 1982, Kudaka et al. synthesized crystalline SrTiO3 powders by the decomposition of oxalic co-precipitate and this coprecipitation method was improved in the 1990s1. Compared to that by the solid state reaction, the SrTiO3 powder by the co-precipitation method has a more homogeneous chemical composition and a finer particle size. However, it is also difficult to prepare an electric device with excellent properties using these powders because high temperature treatment through the above processes readily leads to the agglomeration and inhomogeneity of the particles. In this work, we have used the hydrothermal process to obtain praseodymium strontium titanate (SrxPr1-xTiO3) nanoparticles which were characterized using transmission electron microscopy (TEM), energy dispersive X-ray spectroscopy (EDS) and raman spectroscopy. For the synthesis, a solution A consisting of 0.2683 g of SrCl2 dissolved in 15 ml of methanol was mixed with a solution B consisting of 0.1560 g of metallic potassium dissolved in 15 ml of methanol. The mixture was oxygen degassed with argon (ultra-high purity from Infra ®) under magnetic stirring by 2 hours, precipitating KCl. After that, 0.3659 g of titanium (IV) butoxide was added maintaining the magnetic stirring during 10 minutes. The mixture reaction was poured into a steel-Teflon cylindrical autoclave filled to 2/3 of its capacity. The autoclave was introduced to a pre-heated oven at 200 °C by 24 hours. The product of reaction was filtered and washed with distilled water and a solution of HCl 0.1 N. The obtained particles were dried at 90 °C by 24 hours. Particles with nano and submicron size below 100 nm were observed by TEM. EDS indicates that the main elements (Sr, Ti, Pr) are present but it was also observed the presence of SrCO3 in some samples; however the exact role played by the reactant or conditions on the formation of the SrCO3 is not precisely known. The synthesized powder will allows the potential study of the SrxPr1-xTiO3 host as ferroelectric material. Aknowledgements To FAI UASLP 2011 (C12-FAI-0.-10.10), CONACYT (SEP-80843), SEP/CONACYT No.165968 References 1. S. Feng, R. XU Acc. Chem. Res. 2001, 34, 239-247.