Supporting information

advertisement

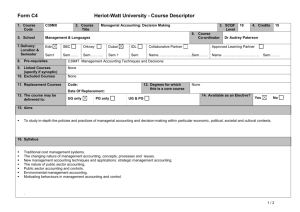

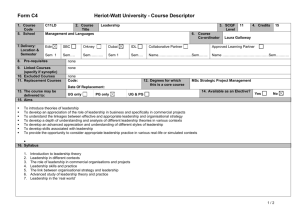

Supporting information for: Low temperature electrical and photo-responsive properties of MoSe2 1. SEM and TEM images 2. Optical photography of the device 3. Photo-responsive phenomenon 4. Experimental details 5. Process of device fabrication 1. SEM AND TEM IMAGES Figure S1| (a) Typical SEM image of the as prepared MoSe2. (b) Topography taken on the edge of the as prepared MoSe2, scanned by TEM. (c) HR-TEM image of marked circular area. Fig. S1 shows typical SEM and TEM images of the as prepared MoSe2. The as prepared MoSe2 were assembled with Nanosheets and formed MoSe2 flower-like nanostructure. The average diameter of the as prepared MoSe2 is about 500 nm. The fringes of the as prepared crimped and the detail HR-TEM image is shown in Fig. S1c. the planes of crystal lattices are obviously observed and the distance between two (002) planes is 0.689 nm, as labeled in Fig. S1c. 2. OPTICAL PHOTOGRAPHY OF THE DEVICE Figure S2| Top view optical photography of the fabricated device with the as prepared MoSe2 The top view optical photography of the device is presented in Figure S2. White parts of two sides in Figure S2 are ITO and the middle part is the as prepared MoSe2. The distance of the gap between two sides is about 121 μm. 3. PR PHENOMENON Figure S3| (a) I-T curve measured using red illumination wavelengths of 650 nm at different temperatures from 300 to 43 K. (b) PR curves under red illumination repeatedly turned on and off. Single cycle and sum of cycles are shown in Figure S3a and S3b. Electrical conductivity reduced as temperatures went down and the shapes of PR current became different at temperatures below 183K. 4. EXPERIMENT DETAILS The method to fabricated MoSe2 were described in our previous work and crystalline structure of the as prepared products was characterized by powder X-ray diffraction (XRD) with 2θ ranging from 10° to 70° at room temperature, using Cu Ka radiation(λ = 0.15406 nm). The surface morphologies and element content of the products was detected by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDX) and high resolution transmission electron microscope (HR-TEM). A Raman spectrum was measured from 100 to 400 cm-1 using a He-Ne laser with a 532 nm wavelength. Ultraviolet visible (UV-Vis) absorption spectroscopy was tested with AvaSpec 2048 UV-VIS-NIR spectrophotometer. First-principles calculations are performed using the Vienna ab initio simulation package (VASP) on the basis of density-functional theory (DFT). The exchange-correction interaction is treated by the generalized gradient approximation (GGA) with Perdew-Burke-Ernzerhof (PBE) functional. The cutoff energy is set to be 500 eV. The Monkhorst-Pack grids of 12121 and 12126 are used for monolayer and bulk MoSe2, respectively. In order to eliminate the interaction between two adjacent monolayer of MoSe2, a vacuum layer larger than 12 Å is adopted. The geometric structures are fully relaxed until the Hellmann-Feynman force on each atom is less than 0.02 eV/Å. In the calculations, the experimental lattice constants of bulk MoSe2 (a=3.288Å, c=12.900Å). 5. PROCESS OF DEVICE FABRICATION Figure S4| Diagram of the fabrication process of device with the as prepared MoSe2. Figure S4 shows a diagram of device fabrication with the as prepared MoSe2. The as prepared MoSe2 were firstly re-dispersed in ethanol by ultrasonic for 30min. The drips containing the as prepared MoSe2 were dropped onto the gap between two ITO electrodes, and then the device was dried in vacuum at 60ºC for 10 minutes. The two steps were repeated for several times. Two copper leads were adhered with silver glue on surfaces of two ITO electrodes.