Chemical Safety Compliance Checklist - OSHA & GHS

advertisement

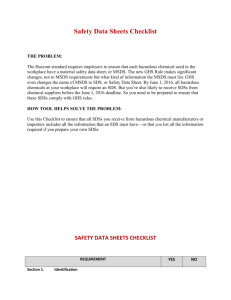

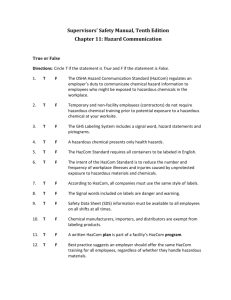

TOOL TYPE CHECKLIST GEOGRAPHY US LAST REVIEWED SOURCE: 011/4/13 CHEMICAL SAFETY COMPLIANCE CHECKLIST THE PROBLEM: Hazardous chemicals are a leading cause of workplace injuries and illnesses. In addition to costly workers’ compensation claims and embarrassing publicity, failure to control chemical hazards at your workplace is a good way to get into deep trouble with OSHA. Here’s a game plan for avoiding these consequences. HOW TOOL HELPS SOLVE THE PROBLEM: Here’s a Checklist you can adapt and use to perform a self-assessment and ensure you comply with OSHA chemical safety requirements, especially under the Hazcom and new GHS standards. Templates and tools from SafetySmart Compliance are provided for members of our service. Members may use this document as is, or as a starting point to customize their own documents. SafetySmart Compliance assumes no responsibility for the effectiveness or enforcement of any of its online templates or tools. Always consult your legal counsel and management before implementing any new policies or procedures at your organization. CHEMICAL SAFETY COMPLIANCE CHECKLIST A. WRITTEN HAZARD COMMUNICATION PROGRAM Item Yes No Comments Company has a written Hazard Communication Program (HCP)? HCP has been read and understood by all affected parties? Person(s) designated to compile chemical inventory and keep it current? Chemical inventory has been compiled? Chemical inventory is kept current? Person(s) designated as having responsibility for obtaining and maintaining MSDS/SDS? Procedure in place for review of MSDS/SDS of new products before they’re purchased to determine presence of hazardous chemicals? Method in place for notifying workers of chemical hazards, including of performing nonroutine tasks? Method in place for notifying onsite contractors of hazardous chemicals used, stored or handled on the site? Procedures in place for working safely with or near hazardous chemicals? HCP includes method for ensuring information related to hazardous materials introduced into work by contractors? HCP includes method for informing building occupants of hazardous materials and usages to which they may be exposed? HCP describes methods of complying with MSDS/SDS, labels, and worker safety information and training requirements? HCP made available to workers and their designated representatives? Schedule in place for modifying HCP to ensure compliance with GHS requirements? B. CHEMICAL LABELS & WARNINGS Person(s) designated to ensure chemical labels are legible, in English and prominently displayed on containers? Audit system in place to periodically check for labels that may have fallen off or become unreadable? Where re-labeling is done, the labeling system clearly conveys the chemical name and hazard warning? All labels and hazard warnings include all information and Templates and tools from SafetySmart Compliance are provided for members of our service. Members may use this document as is, or as a starting point to customize their own documents. SafetySmart Compliance assumes no responsibility for the effectiveness or enforcement of any of its online templates or tools. Always consult your legal counsel and management before implementing any new policies or procedures at your organization. hazard symbols required by Hazcom and/or GHS? All workers informed of hazards associated with chemicals contained in unlabeled pipes in their work areas? Schedule in place for ensuring that all Hazcom labels are replaced with new GHS labels by June 1, 2016? C. MSDSs & SDSs System in place to ensure each hazardous chemical has a proper MSDS or SDS? All MSDSs/SDSs are in English? System in place to review for and remedy missing, incorrect, incomplete or out of date MSDS/SDSs? All labels and hazard warnings include all information and hazard symbols required by Hazcom and/or GHS? MSDSs/SDSs kept in a binder in an area where they are immediately available to all affected workers during all shifts? System in place for auditing compliance with MSDS/SDS compliance? System in place for ensuring MSDSs/SDSs are received with all shipments of hazardous chemicals brought into the workplace? System in place to ensure old MSDSs/SDSs are replaced with new ones? MSDSs/SDSs or key information from them retained for at least 30 years? Schedule in place for ensuring that all MSDSs are replaced with new SDSs by June 1, 2016? D. WORKER TRAINING & SAFETY INFORMATION All exposed workers receive Hazcom training? Training is provided by a person who’s knowledgeable in the Hazcom standard and familiar with the specific chemicals used in the workplace? All exposed workers to receive GHS training by Dec. 1, 2013? Templates and tools from SafetySmart Compliance are provided for members of our service. Members may use this document as is, or as a starting point to customize their own documents. SafetySmart Compliance assumes no responsibility for the effectiveness or enforcement of any of its online templates or tools. Always consult your legal counsel and management before implementing any new policies or procedures at your organization.