chemical hygiene plan (chp) - Southern Connecticut State University

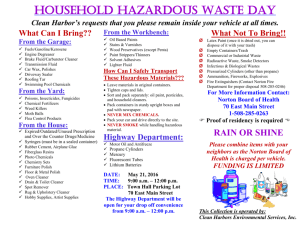

advertisement