srep02448-s1

advertisement

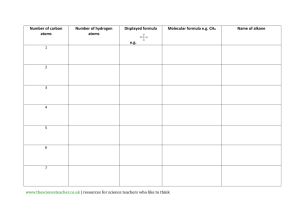

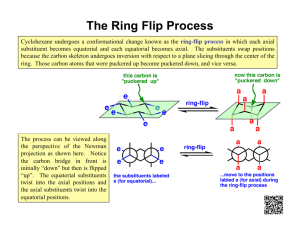

Supplemental Material Spiral Patterns of Dislocations at Nodes in (111) Semi-coherent FCC Interfaces Shuai Shao1, Jian Wang1,, Amit Misra2, Richard G. Hoagland1 1 2 MST-8, Los Alamos National Laboratory, Los Alamos, NM 87545 USA MPA-CINT, Los Alamos National Laboratory, Los Alamos, NM 87545 USA Figure S1. Simulation cell showing mobile region that contains Cu atoms (orange) in the upper crystal and Ni atoms (black) in the lower crystal, and the fixed region (brown). The semi-fixed region acts as a fixed boundary during relaxation once the shear strain is applied. The thickness of semi-fixed region in the y-direction is 1 nm (two times of the cut-off distance of the interatomic potentials) for the two crystals [1]. Both crystals take the same coordinate, x along [112̅], y along [111], and z along [11̅0]. Corresponding author: Dr. Jian Wang, Phone: +1 505 667 1238, E-mail: wangj6@lanl.gov 1 Figure S2. The dependence of dislocation patterns on interface stacking fault energy. By modifying the Cu-Ni cross-pair interaction, interfacial stacking fault energy (ISFE) was varied from -17.6 mJ/m2 to 245 mJ/m2. It is evident that the areal ratio of fcc/hcp increases as ISFE increases. Most importantly, the SP feature at nodes is evident in all cases. 2 Figure S3. The (111) low-angle twist boundaries in Cu, Al [2] and Ag [3]. The calculated stacking fault energies are 45 mJ/m2 for Cu, 146 mJ/m2 for Al, and 18 mJ/m2 for Ag. The twist angle θ =2˚. The distance between adjacent nodes is 7.3 nm in Cu, 8.2 nm in Al, and 8.3 nm in Ag, in consistence with the prediction according to Frank’s formula [4,5]. The dislocations are mostly pure screw in nature and do not twist around the nodes. 3 Figure S4. The Ag-Cu semi-coherent interface. Three pure edge Shockley partials (orange lines) form in the interface. The interface dislocation lines are straight. The distance between the adjacent nodes is 2.2 nm. (b) Atoms around the node experience the displacements towards the center of the node, but no twisting around the node. Atoms are colored according to the excess potential energy. Ag atoms are on the top. References [1] Wang, J., Hoagland, R. G., Hirth, J. P. & Misra, A. Atomistic simulations of the shear strength and sliding mechanisms of copper–niobium interface. Acta Mater. 56, 3109-3119 (2008). [2] Zope, R. R. & Mishin, Y. Interatomic potentials for atomistic simulations of the Ti-Al system. Phys. Rev. B 68, 024102 (2003). [3] Williams, P. L., Mishin, Y. & Hamilton, J. C. An embedded-atom potential for the Cu–Ag system. Modelling Simul. Mater. Sci. Eng. 14, 817-833 (2006). [4] Hirth, J. P., Pond, R. C., Hoagland, R. G., Liu, X. Y. & Wang, J. Interface defects, reference spaces and the Frank–Bilby equation. Prog. Mater. Sci. 58, 749-823 (2013). [5] De Hosson, J. Th. M. & Vitek, V. Atomic structure of (111) twist grain boundaries in f.c.c metals. Phil. Mag. A 61, 305-327 (1990). 4