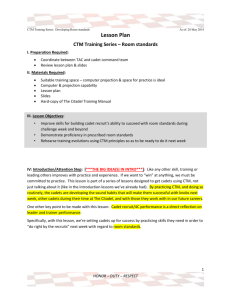

Kim Hotstart Engineering Lab Test Report

advertisement

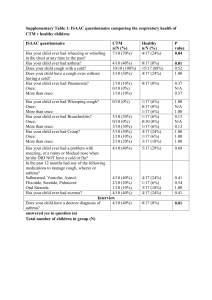

Hotstart Engineering Lab Test Report Test No.: 100826000 Project No.: Report Name: Avista – DDC S60 Deere 6068 Power usage Report Written By: M. Merritt Tested By: R. Delke / D. Fricke Date Started: 04/21/10 Date Completed: 05/27/10 Part No.: 1500W CTM, 1500W TPS, 2500W CTM, 2500W SB Customer: Avista Reason for the Test: Hotstart has been working with Avista to determine the savings in power consumption when going from natural to forced circulation heating systems. Previous testing has been performed showing power savings. The purpose of this test is to finalize the analysis by running the systems in a more controlled atmosphere than the previous tests. Test Goal(s): Determine the power savings of the forced circulation systems for the Detroit Diesel Series 60 engine and John Deer 6068 engines at 0°F, 30°F, 50°F and 80°F. Test Description: Set up a DDC S60 and JD 6068 engine in the environmental chamber. Cold soak the engine and then run the heating systems for 24hrs while monitoring amperage and voltage. Additionally, monitor the temperature of the engine to determine if it is heated effectively. Use both thermocouples and Inferred Images to determine the temperature. Document1 12/8/03 Rev 1 Set-Up: VOLTAGE T-STAT SETTING RUN TIME 120VAC 100-120°F 24HRS FROM COLD SOAK ENVIROMENT HOTSTART COLD CHAMBER, SHROUDED FROM AIR FLOW TEMPERATURE: TC -> FLUKE DATA LOGGER AMPERAGE: OMEGA OM-PLCV VOLTAGE: OMEGA OM-PLCV AVISTA'S IR CAMERA HEATER INLET (FLUID) HEATER OUTLET (FLUID) ENGINE T-STAT (FLUID) OULET FROM ENGINE (FLUID) INLET TO ENGINE (FLUID) HEAD RIGHT REAR (FLUID) HEAD LEFT FRONT (FLUID) BLOCK LEFT REAR (FLUID) BLOCK RIGHT FRONT (FLUID) AMBIENT (AIR) VOLTAGE AMPERAGE DATA RECORDING EQUIPMENT DATA READINGS The heaters used are: DDC S60 – 2500W CTM (forced circulation, CTM251A3-N00) DDC S60 – 2500W SB (natural circulation, SB125210-000) JD 6068 – 1500W CTM (forced circulation, CTM152A3-N00) JD 6068 – 1500W TPS (natural circulation, TPS151GT10-000) Conclusions: The forced circulation system demonstrated 16-64% savings depending on the ambient temperature. At the coldest ambient, both systems were on 100% of the time. Because of this, the forced circulation system consumed more energy because of extra power draw of the pump. However, the natural circulation system did not keep the engine at the desired temperature. Therefore, the results at 0°F should not be factored into the energy savings analysis. Document1 12/8/03 Rev 1 DEERE 6068 yearly usage kW-hrs kW-Hrs in 12hrs % SAVINGS kW-hrs Savings / YR $ SAVINGS / YR CTM 80°F TPS 80°F 1.83 5.16 64% 1339 3769 $ $ 93.76 263.86 2,430 $ 170.09 CTM 50°F TPS 50°F 7.44 10.11 26% 5437 7389 $ $ 380.59 517.21 1,952 $ 136.62 CTM 30°F TPS 30°F 12.58 14.95 16% 9189 10919 $ $ 643.24 764.30 1,729 $ 121.06 CTM 0°F 17.62 -17% 12873 $ 901.08 (1,901) $ (133.10) *TPS 0°F 15.02 10971 $ 767.98 kW-hrs Savings / YR $ SAVINGS / YR x $.07 / hr DDC S60 yearly usage kW-hrs kW-Hrs in 12hrs % SAVINGS CTM 80°F SB 80°F 6.79 10.54 36% 4963 7702 $ $ 347.41 539.13 2,739 $ 191.72 CTM 50°F SB 50°F 16.47 19.77 17% 12028 14443 $ $ 841.95 1,011.03 2,415 $ 169.08 CTM 30°F SB 30°F 22.33 24.21 8% 16309 17686 $ $ 1,141.65 1,238.02 1,377 $ 96.37 CTM 0°F 27.63 -15% 20181 $ 1,412.69 (2,670) $ (186.92) *SB 0°F 23.97 17511 $ 1,225.77 x $.07 / hr *TPS & SB heater did not maintain desired engine temperature at 0°F Document1 12/8/03 Rev 1 It is worth noting that the forced circulation systems did a much better job of maintaining the engine at a consistent temperature. The natural circulation systems had outlet temperatures around 170°F with inlet temperatures around 120°F (figure 1). This excessive outlet temperature results in a large amount of heat being wasted to the ambient leading to increased power consumption. Figure 2 shows the temperature profile of the CTM (forced circulation) on the DDC S60 engine. This shows that the CTM keeps the engine within 40°F where the SB heater has a range of 70°F. The excessive outlet temperature can also be visualized in an IR image (figure 3) Findings: Avista Test #3 60 series DD w/SB125210-200; 240V, 2500W w/100/120 T-stat, 50 degree ambient 200 Temperature in 0F 150 Heater Inlet Heater Outlet 100 Head left rear Head right front 50 Ambient 0 0 180 360 540 720 900 Time in minutes 1080 1260 1440 Figure 1 – DDC60 w/ 2500W SB Document1 12/8/03 Rev 1 Avista Test #12 60 series DD w/2500W, 240V CTM, w/100/120 T-stat @ 50 degrees ambient 200 Temperature in 0F 150 Heater Inlet Heater Outlet 100 Head left rear Head right front 50 Ambient 0 0 180 360 540 720 900 Time in minutes 1080 1260 1440 Figure 1 – DDC60 w/ 2500W CTM Figure 3 – IR Image TPS vs CTM, 30°c ambient Equipment Utilized: Equipment name Calibration Date Equipment name Calibration Date Omege OM-PLCV logger Fluke Data Logger Document1 12/8/03 Rev 1