L15-03326R SI 0628-1

advertisement

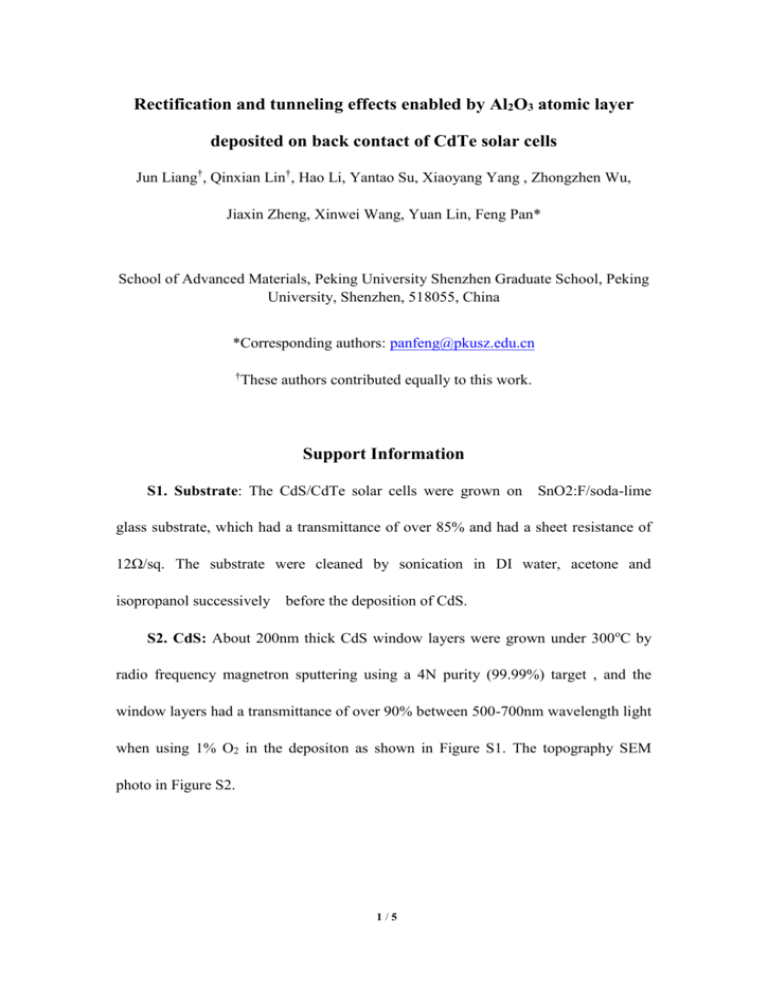

Rectification and tunneling effects enabled by Al2O3 atomic layer deposited on back contact of CdTe solar cells Jun Liang†, Qinxian Lin†, Hao Li, Yantao Su, Xiaoyang Yang , Zhongzhen Wu, Jiaxin Zheng, Xinwei Wang, Yuan Lin, Feng Pan* School of Advanced Materials, Peking University Shenzhen Graduate School, Peking University, Shenzhen, 518055, China *Corresponding authors: panfeng@pkusz.edu.cn † These authors contributed equally to this work. Support Information S1. Substrate: The CdS/CdTe solar cells were grown on SnO2:F/soda-lime glass substrate, which had a transmittance of over 85% and had a sheet resistance of 12Ω/sq. The substrate were cleaned by sonication in DI water, acetone and isopropanol successively before the deposition of CdS. S2. CdS: About 200nm thick CdS window layers were grown under 300 oC by radio frequency magnetron sputtering using a 4N purity (99.99%) target , and the window layers had a transmittance of over 90% between 500-700nm wavelength light when using 1% O2 in the depositon as shown in Figure S1. The topography SEM photo in Figure S2. 1/5 FIG. S1. The transmittance and energy gap of CdS FIG. S2. The CdS film morphology in SEM S3. CdTe: After CdS, 4-5µm CdTe absorber layer was deposited by close space sublimation (CSS) under 550oC and Ar with 15% O2 condition for 20-30 minutes, and the CdTe sources is under 650 oC using 99.999% pure CdTe powder(Alfa Aesar). 2/5 CdCl2 thermal treatment was performed following the CdTe deposition. The CdS/CdTe film was first soaked in a 70%-saturated CdCl2 in methanol solution. The pieces were soaked for 15 min on a hot plate near the boiling point (60-70 oC), then thermal treated under 400 oC for 30minutes in muffle furnace. The CdTe films have a cubic structure and exhibit a strong preferred orientation along the (111) planes parallel to the substrate, as shown in Figure S3. Intensity (a.u.) (111) (220) (311) 10 20 30 40 50 60 deg FIG. S3. XRD patterns of the annealed CdTe thin films The cells were etched in phosphoric acid: nitric-acid: DI-water (NP) to provide a clean, Te-rich surface and then evaporating 3 nm Cu, 150 oC annealing 30 min under N2 atmosphere to form CuxTe (x=1.44~1) intermediate layer.1 The CdTe layer divides into instricstics p and p+ surface parts. The intrinsic carrier density of CdTe is 10 5 cm-3 and increases to 1015 cm-3 after the annealing. 3/5 S4. Al2O3 deposited by ALD: The CdTe sample was transferred into the ALD system for ultrathin Al2O3 deposition. The ALD system is a custom-built, hot-wall stainless steel cylindrical chamber. Ultrahigh purity nitrogen was used as a purge/carrier gas. Al2O3 was grown using Al(CH3)3 (TMA), with water as the oxidant. The substrates were maintained at 120 oC throughout the deposition of Al2O3. The substrate temperature was monitored with a referencethermocouple in the ALD chamber that was previously calibratedagainst an instrumented wafer. Each cycle of Al2O3 growth consisted of a 1 s dose of TMA, a 25 s purge of N2, a 1 s dose of H2O, and a 25 s purge of N2. Finally 40 nm Au layer was thermal evaporated at a rate of 0.2-0.5 Å/s as back electrode. The cell was scribed to 0.5 × 0.5 cm2 area. 1.2 C/Co 0.9 0.6 0.3 0.0 -1.0 Forwards Backwards -0.5 0.0 0.5 1.0 V (V) FIG S4. The C-V curve of Au/1 nm ALD Al2O3/CdTe/FTO 4/5 0.008 0 0.008 0.5 nm 0.008 1 nm 0.000 Imag(U)/V 0.004 90 Hz 0.006 200 Hz Imag(U)/V Imag(U)/V 400 Hz 0.004 0.004 0.002 0.000 0.000 -0.025 -0.020 -0.015 -0.010 -0.005 0.000 -0.025 -0.020 -0.015 -0.010 -0.005 0.000 -0.025 -0.020 -0.015 -0.010 -0.005 0.000 Real(U)/V real(U)/V real(U)/V 0.016 5 nm 3 nm Imag(U)/V Imag(u)/V 0.008 600 Hz 400 Hz 0.012 0.008 0.004 0.004 0.000 0.000 -0.05 -0.04 -0.03 -0.02 -0.01 0.00 real(U)/V -0.03 -0.02 -0.01 0.00 Real(U)/V FIG S5. IMVS response of the samples with AlD-Al2O3 of (a) 0, (b) 0.5 nm, (c) 1 nm, (d) 3 nm, (e) 5 nm . References: 1. T. D. Dzhafarov, S. S. Yesilkaya, N. Y. Canli, M. Caliskan, Solar Energy Materials & Solar Cells 85, 371 (2005). 5/5